How Were Manufacturing Best Practices Disrupted by the Pandemic?

The pandemic and ensuing disruption have revealed weaknesses in common manufacturing practices. It's become clear that what many organizations believed to be best practices weren't the best when facing events like COVID-19.

2021 Top Article - Quality in the Era of COVID-19

Every day in 2020 has been somewhat of a surprise, but probably the biggest surprise of all has been how well manufacturers and quality teams have navigated all of the new rules, restrictions, PPE requirements and product mix changes that emerged.

Four Lessons Manufacturers Learned from the Pandemic

Many investments made by manufacturers over the past two years delivered new capabilities and efficiencies that should be carried forward as manufacturers look to the future in search of new business growth.

Accelerating Digital Transformation to Support Post-Pandemic Growth

We have reached a tipping point to reengineer our end-to-end supply chains. Resilience across the entire value chain is critical. You must have the systems in place and ensure there is no over-dependence on any one partner, country, or region.

Manufacturing's Role in Mass COVID-19 Vaccination

But just as important as having a vaccine is having enough personal protective equipment (PPE) to aid in the vaccination of nearly 330 million people across the country. This importance will be a critical turning point for America's manufacturers

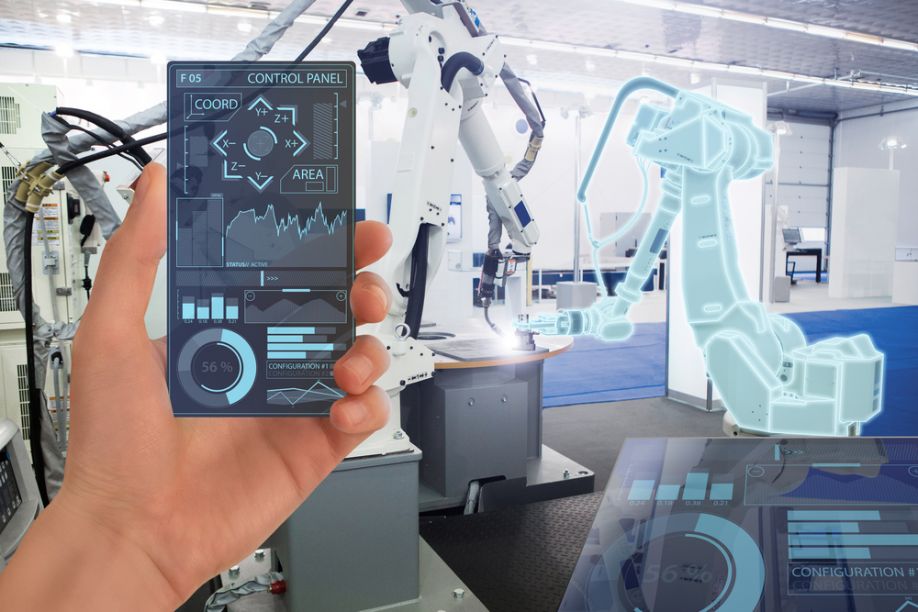

Automation Improving Warehouse Safety Conditions During a Pandemic

Amid rising demand, warehouses have had to increase productivity, but keeping too many workers in a facility can be a health risk. By implementing more robotics, warehouses could artificially expand their workforce.

Case Study: A Task Force Uses Rapid Prototyping to Evaluate an Emergency Medical Device

A team of engineers and medical experts joined forces during the first wave of COVID-19 to rapidly prototype a medical device. Xometry manufactured 9 prototypes in under 3 weeks, providing advice and rapid production for critical decision making.

Automation, IoT technologies help manufacturers weather COVID-19

The manufacturing industry has been heavily impacted by COVID-19 and manufacturers are taking stock of the lessons learned, solutions identified, and technologies available to help weather the pandemic.

Readers Choice 2020: Impact of COVID-19 on the Process Manufacturing Industry; 2020

Read to know how the many process manufacturing businesses around the world impacted by COVID-19 can bounce back.

3D Printing and Printed Materials in 2020: A Challenging Year But Fascinating Times Ahead, Reports IDTechEx

Although the COVID-19 pandemic has interrupted the 3D printing sector and its end users (such as printing bureaus), new directions of travel have nonetheless emerged. Some opportunities have even been directly prompted by the pandemic.

Readers Choice 2020: How to Accelerate Manufacturing Coming out of COVID-19

COVID-19 is still a problem, but with a little luck and a lot of hope, industries are close to reopening. While we see a break in the clouds, no one is quite sure what the road to recovery really means.

Getting used to the new normal with the IoT

As the country faces yet another surge of cases, manufacturers must do everything in their power to prevent outbreaks, keep their people safe and maintain operations. And the Internet of Things (IoT) can help manufacturers accomplish this lofty goal.

How COVID is Expediting Digital Transformation in the Manufacturing Sector

Senior executives seek answers to questions like - Can I make my supply chain agile; Can I do online RFPs and supplier management. Can I run my factories remotely? Can I ensure social distancing on the factory floor by reducing the number of people on the factory floor?

Reshoring or"¦rightshoring? - Why a successful reshoring strategy must focus on quality

The COVID-19 pandemic has exposed the fragility of long, complex supply chains. It has also shown how reliant many US and European companies are on the overseas supply of critical items, bringing to the fore a long-debated issue-are we ready to reshore?

ManufacturingTomorrow - - Fall Product Special

It has been over 6 months without any in person events. With that in mind we are putting together a special feature article for the fall to highlight some of the new products and services our partners have rolled out during that time.

Records 1 to 15 of 31

Featured Product

NORD Delivers Powerful, Reliable Drive Solutions for Demanding Packaging Applications

When you need quality, flexibility and high efficiency, NORD has you covered with complete drive solutions for primary and secondary packaging, end-of-line packaging, and higher-level applications. NORD supports you through the entire life cycle of your drive systems with pre-sales engineering support, online tools, and a global service network. Drive systems for both vertically and horizontally networked technology with all the options for sensor incorporation and integration into the higher-level control system.

Manufacturing and Automation - Featured Company

PI USA (Physik Instrumente)

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1700 people worldwide. PI's customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors and aerospace.

.jpg)