Meshy Unveils AI Creative Lab at CES 2026, Turning AI-Generated 3D Creations into Physical Products With One Click

The leader in 3D generative AI, Meshy introduces the industry's first imagination-to-reality engine, bridging digital creativity and reality

A researcher's long quest leads to a smart composite breakthrough

Yu's team has used an advanced manufacturing technique called additive friction stir deposition to embed functional ceramic particles into metal. The result? A strong, defect-free material that can phase-shift under stress to dissipate energy and, unlike normally brittle ceramics, can be 3D-printed in bulk with full density in the as-printed state, opening up possibilities for practical applications in defense, infrastructure, aerospace, and even high-performance sporting equipment.

AMufacture to Host Industry Showcase Open Day Featuring HP Technology

AMufacture is throwing open the doors of its Portsmouth base for an Open House and Demo Day in collaboration with HP Additive Manufacturing Solutions in the new year.

Momentus Develops Additive Manufactured Fuel Tank with Strategic Partner Velo3D to be flight tested on Vigoride-7 Mission

This milestone demonstrates the potential of additive manufacturing to accelerate innovation in spacecraft design, reduce production timelines, and enable complex geometries that improve performance in demanding space environments.

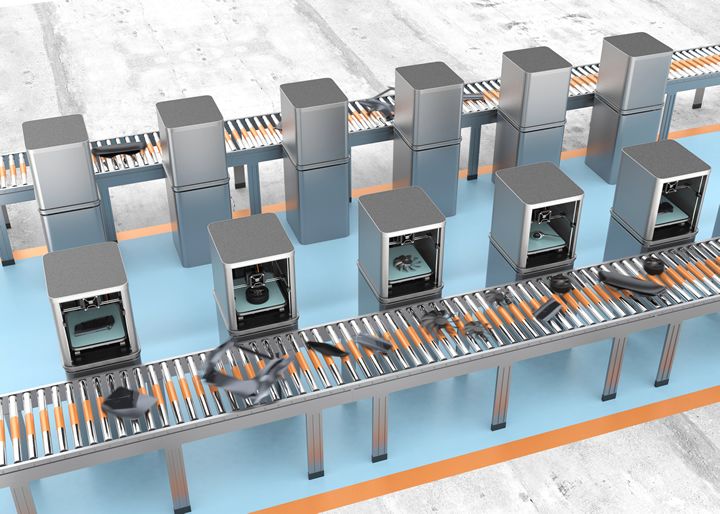

2025 Top Article - AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

Anycubic Opens Deposits for Kobra X, Following Formnext Debut of Its Next-Generation Entry-Level Multicolor FDM Printer

Unveiled alongside the company's latest product lineup in Frankfurt, Kobra X reflects Anycubic's continued focus on simplifying advanced desktop manufacturing workflows.

2025 Top Article - How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

Stratasys Partners with Novineer to Integrate NoviPath FDM Performance Simulation with GrabCAD Print Pro, Reducing Physical Testing Time, and Cost for Load-Bearing Parts

Engineers now able to optimize FDM parts for real applications with dramatically reduced trial-and-error testing, allowing manufacturers to design lighter, stronger FDM parts with greater confidence

Carfulan Group announces record £22.3m year as demand for advanced manufacturing solutions grows

Industry's desire for greater precision, control and additive manufacturing has helped an advanced manufacturing specialist post its best-ever year.

Meltio confirms 2025 as an inflection point for Wire-Laser Metal Deposition adoption across several industries' supply chains

Meltio consolidates during 2025 its leading industrial metal AM case studies and its increasing participation in international events by regularly exhibiting at major trade shows across different industries, such as MilAm, Rapid TCT, EMO Hannover and Formnext during this year for manufacturing technology

Make3D Launches Pratham 3 Rapid High-Speed FDM 3D Printer for Industrial Applications

• Make3D launched Pratham 3 Rapid high-speed FDM 3D printer delivering 500 mm/sec print speeds within 300 × 300 × 300 mm build volume for industrial research and manufacturing applications

• System integrates Klipper firmware with dual control chips, high-flow 30 mm³/s hotend, 300°C hardened nozzle, and ball screw Z-axis with LM guideway XY-axis for velocity-stable printing

Inbolt Unveils Human-Like Bin Picking Solution Powered by On-Arm AI Vision

The new real-time robot guidance system enables flexible and low-cost bin picking for unstructured environments, achieving 95% success rates and sub-1-second pick cycles in live automotive production.

Creality Unveils Scan-to-CAD Workflow Through New QUICKSURFACE Partnership

The collaboration introduces an integrated workflow that streamlines the entire process from 3D scanning to CAD reconstruction for engineering, product design, and manufacturing applications.

Closing Europe's aerospace production gap - EDM automation as part of the answer

EDM removes material using controlled electrical sparks between an electrode and the workpiece submerged in dielectric fluid. This makes it possible to cut extremely hard metals into complex shapes with micrometre accuracy.

Stratasys Supercharges Airbus Production: More Than 25,000 Parts 3D-Printed this Year; 200,000+ Already in Flight

Certified parts printed from Stratasys' ULTEM™ 9085 filament CG reduce aircraft downtime, cut supply chain risk, and lower warehousing costs through distributed manufacturing

Records 1 to 15 of 5012

Additive & 3D Printing - Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Manufacturing and Automation - Featured Company

CSP US Inc.

As a software manufacturer, CSP GmbH & Co. KG offers its customers bespoke solutions for the discrete manufacturing applications. This makes it easy to secure and document the quality of production processes - from development to delivery!