The Next Evolution of Configure-to-Order in Manufacturing

Static bills of materials, disconnected tools, and manual workflows limit scalability. They slow timelines, erode margins, and make it harder to manage increasing product complexity across the lifecycle.

5 Signs it's Time to Hire a Fractional CFO

For many small to mid-sized manufacturers, hiring a full-time CFO isn't economically feasible. That's where a fractional CFO-a part-time, high-level financial expert-can step in to transform the business.

Top 4 Complaint Management Challenges and How To Solve Them

Not only is effective complaints management good business practice, complaints management is also a compliance requirement for companies that adhere to ISO standards or are regulated by the FDA.

Leading with Limits

Through diligent education and awareness of this evolving landscape, businesses and their partners can thrive by using emerging technologies and position themselves competitively.

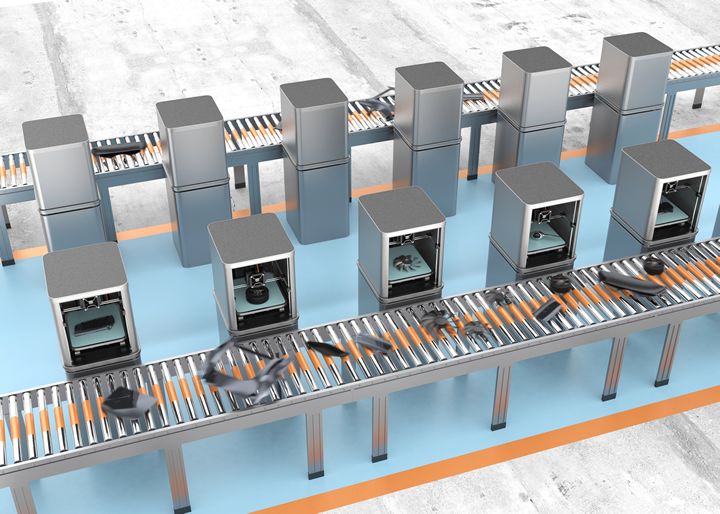

Overcoming the pilot-to-production cost barrier with Edge AI

During pilots, you have all the resources-engineers, servers, hardware-and you'll make it work because you're putting your utmost attention on it. But when you try to replicate that across 100, 200, or 500 locations, it falls on its face.

COMPOSITE CONDUCTOR CORES ENABLE AMERICAN POWER MODERNIZATION

Surging electrical demand from AI-enabling data centers and increased urban power consumption, as well as vast renewable energy production, require upgraded electrical infrastructure.

Rewriting the Rules of Scalable Manufacturing

The project, which fused AM-driven computational design with production-grade investment casting, successfully scaled an intricately engineered part from tens to thousands per day - all without compromising performance, cost-efficiency, or sustainability.

Laying the groundwork for smarter manufacturing - Enhancing factory foundations for reduced downtime, more efficient production

As factories get smarter, they become capable of producing more efficiently, often triggering the need for expansion. This expansion includes better space utilisation, the adoption of newer, larger systems, and an increase in physical footprint.

DFAM: WHY PURPOSEFUL GEOMETRY MUST REPLACE PASSIVE OPTIMISATION

Rather than embracing the full potential of AM, many engineers merely adapt existing designs or lean heavily on software-driven outputs, confusing automation with optimisation.

Upgrade Your Mezzanine Flooring While Avoiding Timely and Costly Replacement

Mezzanine floors are important in many facilities. They provide extra space for storage or work without taking up more ground space. However, they often face heavy use from equipment and people. Over time, this can cause the floor to wear down.

Barriers to investing in CNC automation in 2025 - Transforming CNC automation obstacles into pathways for growth

Here Hakan Aydogdu, CEO at Tezmaksan Robot Technologies delves into these critical obstacles and reveals how innovative technologies and forward-thinking strategies are breaking down barriers, paving the way for a transformative shift in manufacturing.

Battery Manufacturer Cuts Scrap by 90% and Streamlines Prototyping

Lithos has now built a repeatable system through PICO to speed up prototyping, minimize losses, and ensure every change is intentional, traceable, and scalable.

3D Printing Revolution: How Localized Manufacturing Is Reshaping Global Trade

In the realm of advanced manufacturing, robotic large-format additive manufacturing (LFAM) is rapidly emerging as a strategic tool for businesses seeking to bypass traditional trade constraints and build more resilient operations.

From Legacy to Leading: How Manufacturers Can Bridge the Integration Gap

Despite big bets on AI, IoT and cloud platforms, many manufacturers are stuck at the starting line. Why? Because they're trying to race ahead while dragging decades-old systems behind them - and, those systems won't talk to each other.

From Legacy to Leadership: Building the Manufacturing Company of Today

While the idea of a greenfield smart factory is appealing, it's simply not the reality for most companies. What they need isn't a futuristic leap-but a practical step forward. That means modernizing existing operations to build a factory of today.

Records 1 to 15 of 2955

Featured Product

The Wire Association International (WAI), Inc.

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry. WAI hosts trade expositions, technical conferences, and educational programs.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)