Computers for Edge AI, Machine Vision, and Industrial Automation Applications

The market demand for solutions that combine high performance, compact size, and high reliability is rapidly increasing, especially in harsh environments such as smart manufacturing.

Overcoming the pilot-to-production cost barrier with Edge AI

During pilots, you have all the resources-engineers, servers, hardware-and you'll make it work because you're putting your utmost attention on it. But when you try to replicate that across 100, 200, or 500 locations, it falls on its face.

Energy Efficiency in Manufacturing and Data Management

Energy consumption is growing exponentially, while energy creation is increasing only incrementally. This imbalance requires innovative solutions. At Delta, we tackle this challenge from both sides-enhancing energy creation while optimizing energy consumption.

Edge Computing and AI in Manufacturing

With Tacton we wanted to give users the flexibility and configuration options they need to outfit their facility, while ensuring the system was reliable, secure, and easy to install.

How AI is reshaping the edge computing landscape

How much computing power is needed at the edge? How much memory and storage are enough for AI at the edge? Minimum requirements are growing as AI opens the door to innovative applications that need more and faster processing, storage, and memory.

Embrace the edge to avoid unscheduled downtime

One of the key metrics for process efficiency is overall equipment efficiency (OEE). This KPI is related to the availability, performance and quality of the production process. High OEE often means good revenue.

Sustainable manufacturing at the edge

In the wake of landmark climate event, COP26, manufacturers are striving to align their activities with the global net zero targets. But the sector has a long way to go. It currently produces more than 16 gigatons of carbon dioxide (CO2) each year.

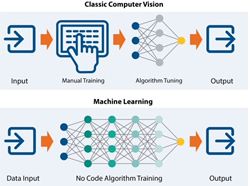

AI for End-to-End Quality

Artificial intelligence (AI) is gaining favor as a solution for quality problems, but many manufacturers struggle with the perceived cost and complexity of implementing new technology.

AIoT and Edge Analytics: a Powerful Combination

Swedish philosopher Nick Bostrom once said, "machine intelligence is the last invention that humanity will ever need to make". AI decision making, with real time communication and data analytics, has the ability to transform the way manufacturers understand machines.

Leverage the Edge - the Benefits of Processing Data at the Edge, Not the Cloud

The edge is an essential layer of the manufacturing technology stack. Machines on the factory floor collect vast amounts of raw data from various sources using numerous protocols, which all needs to be processed quickly to gain actionable insight.

How to manage a complex network of new and legacy equipment

With rapid advancement in automated and connected technologies, managing both new and old equipment simultaneously can be a challenging balancing act.

Securing the OT edge with SASE

Manufacturers have become increasingly reliant on cloud-based resources, such as Software-as-a-Service (SaaS) applications and data migrating from the data center to multi-cloud environments. This requires a new model for secure network access.

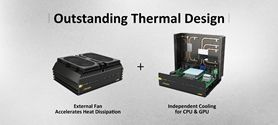

10 Fundamental Computer Hardware Needs For Edge Computing

To cope with increasing amount of data, edge computing hardware is being deployed to alleviate the burdens placed on the cloud and data centers. So, what are the computer hardware needs for edge computing? We will answer this question in much detail.

Edge AI technology In Manufacturing Operations

A downside of so much automation is that there is now a heavier dependence on machinery/robots to perform action. For some lines, if one of robot goes down, the entire line does.

What's in Store for Edge Computing Deployments in 2020

During POC projects in the last few years, many organizations have confirmed the benefits that IIoT can bring to a wide variety of industries - and IoT spending is expected to reach $1.1 trillion by 2025, according to IDC.

Records 1 to 15 of 18

Featured Product

Datanomix Production Monitoring

Datanomix Production Monitoring delivers instant visibility into your shop floor performance. Through real-time alerts, simple machine connectivity, and our kick-ass coaching, you'll catch inefficiencies early, align your team with meaningful metrics, and respond faster to issues before they escalate. The software adapts without operator input and works out of the box with purpose-built Tracks (Efficiency, Delivery, Tooling, and more). Production Monitoring arms you with the data to make more, waste less, and lead with confidence. And while real-time visibility keeps you sharp in the moment, historical insights ensure you're learning from the past to drive ongoing continuous improvement.

Manufacturing and Automation - Featured Company

EMERSON

Emerson's industry-leading portfolio enables us to identify and confront the challenges of an increasingly complex and unpredictable marketplace from a position of strength, driving near- and long-term value as a trusted partner for our customers.