Engineering - Articles, Stories & Interviews

AI for Product Data Management: A Key Component for Smarter Manufacturing

AI improves data quality by reducing errors and inconsistencies introduced by manual intervention. Manual errors may not seem like a huge deal, but they can easily disrupt time-to-market or channel accuracy.

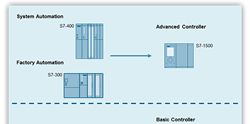

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can't Afford to Wait

This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, "I need parts, not charts." And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what's happening on their shop floor.

Rugged Surface Pro xCase with Badge Readers Elevates Workforce Safety & Mustering for Umicore

When global materials technology and recycling leader Umicore set out to modernize employee tracking and emergency mustering processes, they turned to Savance Workplace for a customized digital workforce management solution.

2025 Top Article - Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

2025 Top Article - AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

2025 Top Article - Monitoring Tools for Manufacturing Plant Maintenance

Electrical power delivery systems are usually the most impactful on plant operation. The cost of failure of certain pieces of equipment can quickly escalate into multi-millions of dollars of equipment replacement costs and production downtime.

Engineering - Featured Stories

Discovering Manufacturing Bottlenecks Through AI and Machine Learning Analysis

.jpg)

Manufacturing slowdowns come from many sources. That diversity makes it challenging for executives to identify the top causes without help. Well-trained AI and machine learning algorithms can analyze the data and recommend suggestions for improvement.

How private 5G empowers manufacturers to maximize AI use cases

While Wi-Fi networks have historically met the basic wireless connectivity needs of some manufacturing operations, they increasingly fall short in more complex, high-demand industrial environments.

Why B2B IAM Is Essential for Modern Manufacturing

VPN access is widely used without strong safeguards regarding whether those users should be trusted or what they're entitled to access. Cybercriminals are increasingly targeting VPN setups.

Engineering - News Headlines

Challenging Weather and Lighting Conditions Prove No Problem for the New Flir FCB-Series AI Infrared Analytics Camera

New Thermal Sensor with Deep-Learning Video Analytics Safeguards Locations by Detecting, Tracking and Analyzing All Perimeter Breaches.

Altech Announces Tough, IP67 Enclosures With Unique Seal System for Harsh Environments

These rugged, UL- and CSA-approved units are made from high-quality, lightweight polycarbonate and feature a unique "Drain Protect" seal system to protect against most environmental influences.

IDS enters 2026 with strong momentum

Clear growth targets and a 3-year manufacturer's warranty

Engineering - Featured Product

Improve productivity and achieve consistent, high-quality welds with mechanized welding solutions.

Improve productivity and achieve consistent, high-quality welds with mechanized welding solutions.

We have the right welding system for every application. Our solutions are the ultimate in precision and efficiency, meeting the full scope of requirements for quality and reliability in tank, vessel, and pipeline construction in particular. We also offer custom solutions that stand up to any challenge. Working with our mechanized circumferential welding systems, you can weld components of very different sizes and weight classes-thanks to systems ranging from compact welding cells for smaller components through to robust systems for heavy workpieces. Cutting-edge technology and premium materials deliver top results, making our welding systems incredibly versatile, simple to use, and easy to maintain. Even welds, high process stability, and less rework are just a few of the advantages-and you can benefit too.

Engineering - Featured Company

Fronius Perfect Welding

We aspire to produce more than just welding systems, which is why we are the innovation leader for arc welding and are constantly developing welding processes further. In addition to welding technology for robot applications, we offer solutions for manual gas shielded arc welding, for MIG/MAG, TIG, and MMA welding processes. We also implement automated, complete welding solutions tailored to customer requirements in the field of welding automation. After all, welding creates connections - between metals, between industries, and between people. Connected by the arc, by passion, by the beat of welding.

.jpg)