Maximizing Operation Efficiency through Manufacturing Processes

Cross-functional collaboration isn't just helpful, it's the backbone of a smooth new product introduction. You can have the best design on paper, but if engineering, operations and supply chain aren't aligned from day one, you're setting yourself up for late-stage surprises.

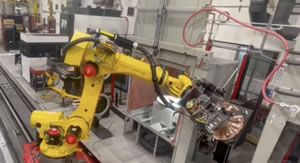

Transforming High-Precision Manufacturing through Advanced Automation

Honeywell faced growing demands for their high-precision manufacturing processes, coupled with labor shortages and strict quality standards. Their manual processes were becoming the limiting factor-causing bottlenecks, inconsistent quality, and increased scrap.

Reducing Waste in Manufacturing for Safer, More Reliable Production

As the hardware of the future continues to evolve to become more complex and technologically advanced, so too are the ways in which we manufacture. Innovation requires adaptation, and new processes are needed for compliance, reliability and most of all - less waste.

6 Steps to Build a Continuous Improvement Culture in American SMEs

This blog outlines 5 practical, proven steps that leaders in American SMEs can use to build a culture where improvement isn't a project-it's just how work gets done.

Are Errors Eating Your Profits? Unlocking Lost Manufacturing Capacity and Profits

The Practical Playbook for Agile Manufacturing Executives. Are errors eating into your capacity and profits? This question resonates with manufacturing leaders across North America who are grappling with an increasingly challenging production environment.

Why Cloud-Based EDI Is Imperative for Manufacturing

An effective EDI in manufacturing must be as agile, accurate and secure as leading manufacturers themselves. The only way to achieve that is to use a cloud-based alternative to conventional solutions.

A Packaging Look-Ahead for 2024 and Beyond

As packaging converters and their brand/retailer clients look to the future, there are four key areas of focus that are getting a lot of attention: Artificial Intelligence, Sustainability, Automation, and Hiring and Retaining talent.

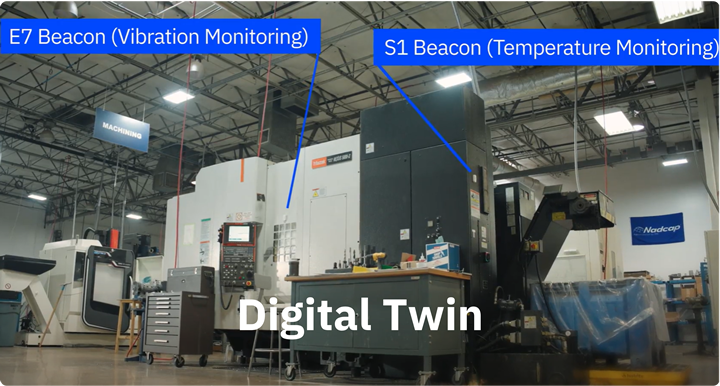

Using AI to Fill Blind Spots and Revolutionize Manufacturing Processes

One of the biggest pain points in the manufacturing industry is that most processes are not instrumented, resulting in upwards of 75% of digital blind spots. This lack of visibility on the shop floor leaves manufacturers without a complete data picture.

More assembly processes in a smaller space and using less energy

The market for electronic controllers for vehicles is growing. The driving forces are electrification and the increasing number of assistant systems. However, this does not change the competitive pressure to which manufacturers are exposed.

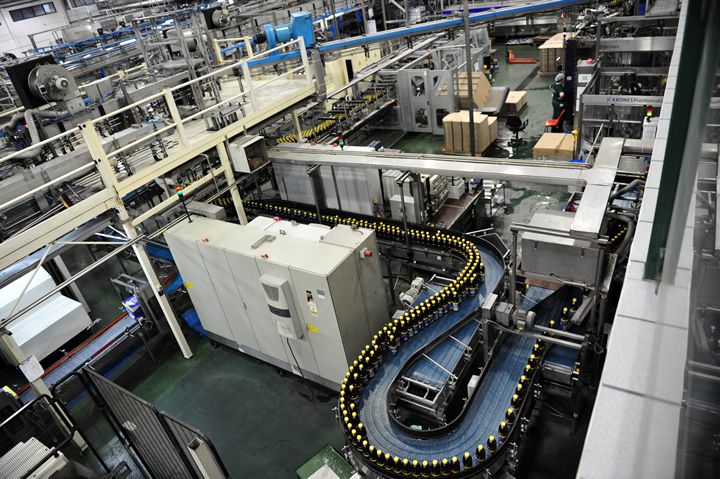

The secret to success in food & beverage manufacturing

OEE takes into account machine availability, performance, and quality to provide a holistic view of a production line's efficiency. By capturing and analysing real-time data, LineView helps manufacturers improve OEE, thereby maximising the utilisation of existing resources.

Mastering Configurable BOM Complexity

Products have become more complex with additional software and configuration options to meet customization demands; simultaneously, BOMs have also become more complex.

Induction Seal vs Heat Seal: What's the difference?

The main difference between an induction seal and a heat seal is the way in which the seal is created. Induction sealing uses electromagnetic induction to generate heat and create a tamper-evident seal, while heat sealing uses heat to bond two materials together.

Zebra Survey Shows Eight-in-10 Millennials Expect More Transparency in Automotive Manufacturing

Study reveals high demand for knowing the origin and sustainability level of materials and automotive parts as well as receiving an end-to-end view of the manufacturing process

Fulfillment Optimization is Not an Impossible Task

Part of optimizing any logistics operation is to make sure that you are not incurring additional and lasting costs on the path to speeding up your rate of fulfillment. The goal is to move more product through your system and out the door - but you also must watch expenses.

Variability Reduction: Why Important To Manufacturers?

A routine issue faced by most manufacturers is their process variation. Variability in the process can wreak havoc on product quality and customer satisfaction. Also, it has a severe impact on revenue, cost, and margins.

Records 1 to 15 of 15

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

EMERSON

Emerson's industry-leading portfolio enables us to identify and confront the challenges of an increasingly complex and unpredictable marketplace from a position of strength, driving near- and long-term value as a trusted partner for our customers.

.jpg)