Beyond the Device: The Real Drivers of Industrial Mobility

Accessories don't just complement rugged devices, they complete them. They turn durability into productivity, resilience into results, and hardware into workflow platforms.

Reducing Waste in Manufacturing for Safer, More Reliable Production

As the hardware of the future continues to evolve to become more complex and technologically advanced, so too are the ways in which we manufacture. Innovation requires adaptation, and new processes are needed for compliance, reliability and most of all - less waste.

Is Motion Waste Hurting Your Warehouse Productivity?

Warehouses are complex operations with a lot of functions and moving parts happening simultaneously. While there are ample opportunities to improve productivity, it's not always clear where your efforts will bear the most fruit.

Variable speed drives: the dark side

According to ABB, the power and automation company, the addition of a VSD can reduce energy consumption by as much as 60 per cent. This means that, if a 90-kW motor in continuous operation is combined with a VSD, financial savings can amass to over £9,000 per year.

The Earth's environment is in code-red status, but new digital solutions can meet the challenge.

Plant controller systems based on static models are not responsive enough to adapt to changes and prescribe actions to insure optimal outcomes. As a result, set points are adjusted every now and then by operators who hunt for good conditions.

Readers Choice 2020: Strategic Approaches for Implementing Automation in Industrial Manufacturing

The adoption of automated systems should be based on a clearheaded commercial and technical analysis to strike the right balance between speed, cost, quality and value.

Warehouse Efficiency Improves Operations

According to supply chain and logistics consulting firm MWPVL International, when the storage capacity of a warehouse distribution center surpasses the 85% utilization level, there is also a reduction in productivity.

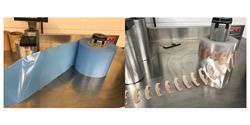

How to Increase Run Rates, Reduce Waste and Maximize Profitability

When you are looking for greater efficiency, higher run rates or less waste in your production, dont forget to look at the little things.

Records 1 to 8 of 8

Featured Product

Datanomix Production Monitoring

Datanomix Production Monitoring delivers instant visibility into your shop floor performance. Through real-time alerts, simple machine connectivity, and our kick-ass coaching, you'll catch inefficiencies early, align your team with meaningful metrics, and respond faster to issues before they escalate. The software adapts without operator input and works out of the box with purpose-built Tracks (Efficiency, Delivery, Tooling, and more). Production Monitoring arms you with the data to make more, waste less, and lead with confidence. And while real-time visibility keeps you sharp in the moment, historical insights ensure you're learning from the past to drive ongoing continuous improvement.

Manufacturing and Automation - Featured Company

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

.jpg)