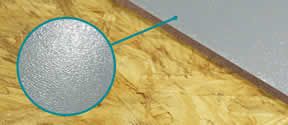

Upgrade Your Mezzanine Flooring While Avoiding Timely and Costly Replacement

Mezzanine floors are important in many facilities. They provide extra space for storage or work without taking up more ground space. However, they often face heavy use from equipment and people. Over time, this can cause the floor to wear down.

How Product Catalog Management Supports Circular Supply Chains in Manufacturing

Most ERP and PLM systems track products only through production and sale, not reuse, refurbishment, or recycling. This fragmentation causes material loss, inefficient remanufacturing, slow reverse logistics, and compliance failures.

The Role of Conveyor Systems in Warehouse Logistics

In many warehouses there is still a reliance on manual labour and heavy lifting which can put workers at risk, as well as compromise on efficiency. This is where conveyor systems can completely revolutionise a warehouse operation.

The Interplay Between Robotics and Artificial Intelligence in Manufacturing

AI and robotics make the factories of the future smarter and more efficient. Manufacturers need to use these exponential technologies to gain a competitive advantage.

Best Practices for Safer Factories in 2024: How to Improve Material Handling Applications

This article outlines the top tips to apply in the year ahead and improve cart safety through proper caster selection, maintenance, replacement, and training.

Tompkins Industries Reaches New Heights with its Vertical Lift Automation System

The automated vertical lift project kicked off in January 2022 and relied heavily on technical assistance from the team at PathGuide to incorporate the automated vertical lift into Latitude.

Smart Technology Developer Optimizes Processes With RFID-enabled Workforce Tracking

Caron Engineering needed a smart, secure RFID reader that would allow them to add operator authentication and log-in to their solutions for US and international CNC machining market customers and to enable those customers to use their current employee badge system.

Improving Materials Processing With Robotics

End users are looking to machine builders to provide innovative solutions that improve upon the speed and accuracy of manual-based applications while maintaining the same level of flexibility.

Is Motion Waste Hurting Your Warehouse Productivity?

Warehouses are complex operations with a lot of functions and moving parts happening simultaneously. While there are ample opportunities to improve productivity, it's not always clear where your efforts will bear the most fruit.

Material Handling Trends Require the Need for Speed

Increased demand for quick and reliable fulfillment is putting added pressure onto warehouses and distribution centers to prevent supply chain disruptions from lag in data, equipment failure, and design processes.

Automating Materials Handling - Automation to Support Supply Chain Woes

Unpredictable markets, an unstable procurement chain and impatient customers are just a few challenges your supply chain deals with. Balancing supply, demand and capacity has reached such a level of complexity that automation is increasingly sought after.

Optimizing Warehouse Cold Storage Capacity and Longevity

Freezer and cooler storage pallet rack must withstand some of the greatest forklift abuse in warehouse material handling. This can be attributed to a number of factors including confined space, slick surfaces, and the cold temperatures.

Automatic Photo Portal for the Documentation of Intralogistics Processes

Due to digitalization in Industry 4.0, internal logistics is subject to constant change. Internal traceability, i.e. the tracking of goods in the warehouse or production facility, is increasingly playing a key role.

Reaching New Levels of Operational Efficiency With Just-in-time Manufacturing

As we move further down the road to the full digitalization of business, this idea of maximizing outputs while minimizing operational costs is essential to keep manufacturing efficient and match market demand.

Material Handling Guidance for Additive Manufacturers from Essentium

Here's some guidance on best practices for material handling and advice on the proper equipment to implement a material handling workflow at your facility.

Records 1 to 15 of 20

Featured Product

Improve productivity and achieve consistent, high-quality welds with mechanized welding solutions.

We have the right welding system for every application. Our solutions are the ultimate in precision and efficiency, meeting the full scope of requirements for quality and reliability in tank, vessel, and pipeline construction in particular. We also offer custom solutions that stand up to any challenge. Working with our mechanized circumferential welding systems, you can weld components of very different sizes and weight classes-thanks to systems ranging from compact welding cells for smaller components through to robust systems for heavy workpieces. Cutting-edge technology and premium materials deliver top results, making our welding systems incredibly versatile, simple to use, and easy to maintain. Even welds, high process stability, and less rework are just a few of the advantages-and you can benefit too.

Manufacturing and Automation - Featured Company

EMERSON

Emerson's industry-leading portfolio enables us to identify and confront the challenges of an increasingly complex and unpredictable marketplace from a position of strength, driving near- and long-term value as a trusted partner for our customers.