Challenging Weather and Lighting Conditions Prove No Problem for the New Flir FCB-Series AI Infrared Analytics Camera

New Thermal Sensor with Deep-Learning Video Analytics Safeguards Locations by Detecting, Tracking and Analyzing All Perimeter Breaches.

Altech Announces Tough, IP67 Enclosures With Unique Seal System for Harsh Environments

These rugged, UL- and CSA-approved units are made from high-quality, lightweight polycarbonate and feature a unique "Drain Protect" seal system to protect against most environmental influences.

IDS enters 2026 with strong momentum

Clear growth targets and a 3-year manufacturer's warranty

Youngstown Innovation Hub Solicits White Papers on IP Generation & Technology Development

Funded through the Youngstown Innovation Hub, the project call makes a total of $300,000 available to support regional innovation, accelerate the transition of technologies to market-ready solutions, and foster collaboration among industry, academia, and government stakeholders. Up to three awards are anticipated.

ACCUMOLD BRINGS MICRO MOLDING PRECISION TO PHOTONICS WEST 2026 AS OPTICAL INNOVATION ACCELERATES

Visit Accumold at Booth #1848 to explore how micro molding is enabling photonics innovation through miniature plastic components that demand exceptional dimensional control and repeatability. In photonics, performance often comes down to alignment, where even small deviations can affect signal integrity, coupling efficiency, or long-term stability.

Trelleborg Exhibits Innovations and Solutions for Medical Components and Devices at MD&M West

Integrated Solutions simplifies development and manufacturing systems, enhancing supply chains and logistics processes, driving cost savings?through bundled purchasing processes and consolidated audits, shipping and logistics.

Automated Industrial Robotics Inc. Acquires KAON Automation

Transaction Further Strengthens AIR's Presence in Ireland and Expands Global Capabilities in Developing Automated Systems for Medical Device Assembly and Aseptic Filling

AI for Product Data Management: A Key Component for Smarter Manufacturing

AI improves data quality by reducing errors and inconsistencies introduced by manual intervention. Manual errors may not seem like a huge deal, but they can easily disrupt time-to-market or channel accuracy.

New eBook from Mouser Provides an Engineering Guide to RF Design and Applications

The eBook delves into key radio frequency (RF) design topics ranging from signal chain fundamentals and antenna selection to testing, certification, and digital integration.

FUGO Precision 3D and Graphy Forge Strategic Partnership to Accelerate Advanced Material Integration Ahead of LMT 2026 Launch

Spark Factory Goes Live with DeSL's End-to-End PLM Solution

The implementation includes several key DeSL modules: Line Planning, Workspaces, Fast Product Management (FPM), Tech Packs, Fast Tech Pack Management (FTM), and POM Templates, Adobe Illustrator Plug-in, Critical Path/Request for Development (RFD), and Internal Discussion Threads. All designed to connect design, development, and production in one streamlined digital environment.

Packaging Recycling Summit will be held June 15-17, 2026 at the Loews Chicago O'Hare Hotel, Rosemont, Illinois.

Call for Speakers Now Open: Industry Leaders Invited to Share Expertise on Designing the Circular Future

From Idea to Print: Creality SPARKX i7 Debuts at CES 2026 for Everyday Creators

The showcase highlighted Creality's latest progress in intelligent, AI-enabled fabrication, demonstrating how advanced 3D creation technologies are becoming more accessible, intuitive, and closely aligned with everyday creative use cases.

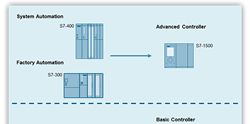

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can't Afford to Wait

This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

HARTING Americas Drives Global Growth with 33% Sales Increase

Global industrial connectivity manufacturer reports 17% worldwide growth and outlines key industry trends for 2026

Records 1 to 15 of 12029

Engineering - Featured Product

Datanomix Production Monitoring

Datanomix Production Monitoring delivers instant visibility into your shop floor performance. Through real-time alerts, simple machine connectivity, and our kick-ass coaching, you'll catch inefficiencies early, align your team with meaningful metrics, and respond faster to issues before they escalate. The software adapts without operator input and works out of the box with purpose-built Tracks (Efficiency, Delivery, Tooling, and more). Production Monitoring arms you with the data to make more, waste less, and lead with confidence. And while real-time visibility keeps you sharp in the moment, historical insights ensure you're learning from the past to drive ongoing continuous improvement.

Manufacturing and Automation - Featured Company

OnLogic

OnLogic is a global industrial computer manufacturer who designs highly-configurable, solution-focused computers engineered for reliability at the IoT edge. Their systems operate in the world's harshest environments, empowering customers to solve their most complex computing challenges, no matter their industry. OnLogic has helped more than 70,000 customers worldwide advance their ideas with computers that are designed to last, built to order and delivered in days.

.jpg)