Honeywell faced growing demands for their high-precision manufacturing processes, coupled with labor shortages and strict quality standards. Their manual processes were becoming the limiting factor-causing bottlenecks, inconsistent quality, and increased scrap.

Transforming High-Precision Manufacturing through Advanced Automation

Transforming High-Precision Manufacturing through Advanced Automation

Case Study from | Acieta

The Challenge: Increasing Precision and Capacity

Honeywell faced growing demands for their high-precision manufacturing processes, coupled with labor shortages and strict quality standards. Their manual processes, which once served their needs, were becoming the limiting factor—causing bottlenecks, inconsistent quality, and increased scrap.

They needed a solution capable of handling higher volumes reliably while improving quality and workforce safety.

The Acieta Approach: Building a High-Volume, Integrated Robotic Cell

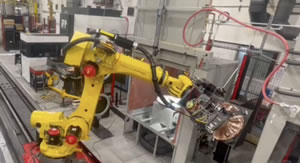

Acieta collaborated with Honeywell Spokane to design and implement a fully integrated robotic system implementing FANUC robots. The process involved detailed engineering and system integration to ensure reliability, precision, and scalability.

Acieta collaborated with Honeywell Spokane to design and implement a fully integrated robotic system implementing FANUC robots. The process involved detailed engineering and system integration to ensure reliability, precision, and scalability.

Core Robotics Operations:

A FANUC R-2000iC/210F on an RTU supported critical handling and transfer functions, complemented by vision systems for precise part location and verification. Two FANUC M20iD/25 robots performed polishing and bead blasting, delivering high-precision finishes with parts-per-billion accuracy.

Component Integration:

The system architecture brought together equipment from different suppliers, including German-built machine tools, Italian wash systems, and Japanese material scanners. Using a SCADA platform for system output monitoring, these devices were integrated into a unified, reliable process.

Custom Tooling Development:

Specialized EOAT tooling was engineered to delicately handle 130 lb fragile components, incorporating polyurethane touchpoints and precise actuators. This development reduced manual intervention steps from twenty-one to just two, enabling operators to concentrate on higher-value tasks.

Results Achieved: Measurable and Impactful

Acieta’s engineering and system integration produced clear results:

Acieta’s engineering and system integration produced clear results:

Quality Improvement:

Yield rose from 85% to over 95%, significantly cutting scrap and rework costs and boosting product consistency.

Labor and Safety Improvements:

The automation replaced 21 manual process steps down to two, reducing the need to hire additional manual labor. Ergonomic risks were eliminated, creating a safer work environment.

Operational Efficiency and Sustainability:

Streamlined workflows utilizing Ignition SCADA provided real-time system performance data, resulting in lower per-unit costs and supporting long-term growth and environmental sustainability.

Investing in Skills: Workforce Development

An important part of this project was training operators to work with the new system. Operators like Darren Fry – Lead Manufacturing Technician, were trained to became in-house automation specialists—learning robot programming, vision system calibration, and digital twin techniques. This fostered a culture of continuous learning, leadership, and technical growth across the organization.

A New Standard in High-Precision Manufacturing

Honeywell Spokane Valley’s project showcases how integrated engineering, advanced robotics, and strategic planning lead to measurable improvements in capacity, quality, and safety. It’s a clear example of modern manufacturing done right—where precision, productivity, and people come together to produce reliable, scalable results.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product