6 Salesforce capabilities for manufacturing sales enablement

This solution complements the core capabilities of Sales Cloud and Service Cloud with a set of industry-specific functionalities and provides advanced automation capabilities for workflows specific to manufacturing sales and customer service.

How Remote Industrial Operators Will Dominate the AI Race

Companies that secure data ownership today are the ones who will lead tomorrow or, in Olympic terms, will earn gold in the AI race.

Mid-size manufacturers and ERP: Striking a balance of cost and guidance

At the end of the day, mid-size organizations face the same operational challenges as their larger counterparts, and should experience the same high level of service, optimized for their budget and needs.

Revolutionizing Machining Operations with Artificial Intelligence

The synergy between AI and CNC machining is set to reshape the future of manufacturing. Embracing these innovations will empower industries to achieve new levels of excellence, driving growth and success in an increasingly complex market.

Understanding What Makes Warehouse Workers Happy

This groundbreaking survey gathered insights from warehouse workers across the United States, exploring their daily challenges, what makes them happy, and what employers can do to improve working conditions.

Integrating the loading process for 100% end-of-line automation

Stubborn organisational silos - both within the company and in partnerships with third-party logistics (3PL) providers - can prevent the automation of important cross-functional processes, such as the loading and unloading of trailers

Implementing AI for Energy Efficiency in Manufacturing

AI for energy efficiency gains requires dedication, but the effort yields an optimized, self-sufficient machine. Early AI adopters using it to progress corporate social responsibility and lower building emissions garner favor among client bases for their initiative.

ENGINEERING THE AMERICAN DREAM

Building the American Dream: Marcus Schneck, CEO at norelem explains how the company's US expansion will support American design engineers in creating exciting new products.

Making Digital Commerce Work for B2B Manufacturing

Digital commerce promises to make B2B manufacturers more efficient while improving customer satisfaction and growing sales. Do work with a partner who has been through this process before to guide your company through the options that are right for you.

Can Stage 3 FSA Confirm Your Safety Instrumented System Is Ready for Operational Use?

The deliverable for a Stage 3 FSA includes a comprehensive report with a Stage 3 FSA checklist derived from a site visit and independent assessment. This report will present findings, including serious deficiencies, recommendations, and general observations.

ISO 9001: What's in it for you?

The decision to implement ISO 9001 is a business decision; and like all business decisions, you have to weigh the costs against the benefits. Also, you can implement ISO 9001 internally and stop there, or you can push ahead to seek certification.

The Role of Automation in Supply Chain Resilience

While automation offers significant benefits for enhancing supply chain resilience, it also comes with challenges and considerations that businesses must address to ensure successful implementation.

Learning From Visionaries: The Stages at IMTS 2024 Feature Technology, Manufacturing, and Industry Leaders

The Stages throughout IMTS feature executive conversations and presentations on AI transformation and empowerment, innovation and change management, digital transformation, growing the defense industrial base, manufacturing infrastructure, and much more.

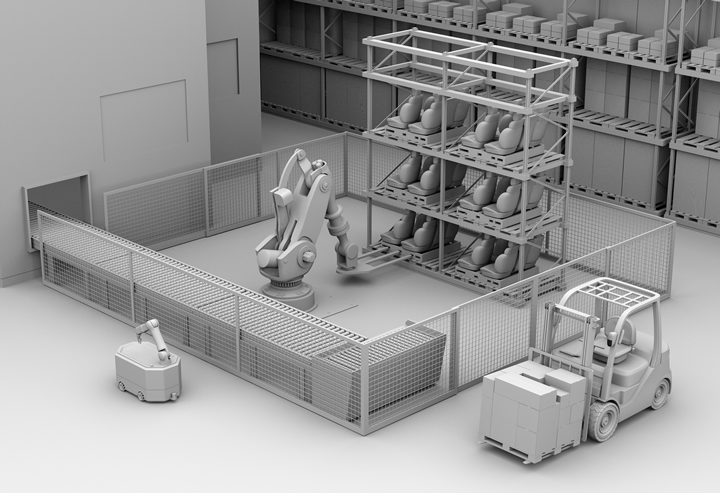

Automation isn't a one-size-fits-all: 5 key considerations for your warehouse

From AI-vision systems revolutionizing inventory management to advanced depalletization solutions streamlining logistics, we'll explore five critical considerations that can make or break your journey toward integrating robotics into warehouse operations.

Error-Proofing: The Key to Modern Manufacturing Success

For manufacturing engineers, a large part of the job is managing and eliminating risks. This process is called error-proofing, or poka-yoke in the industry.

Records 1 to 15 of 1129

Featured Product

Quickbase: The first application platform built for dynamic work

By connecting everything through a single source of truth, the Quickbase platform helps businesses mitigate risk, reduce waste, and cut down on unexpected costs. With automated workflows and granular permissions, the right people will have access to the right information.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)