Raising the Bar for Additive Manufacturing with Expert Service & Delivery - Beyond the Status Quo

Utilising industrial 3D printing for any manufacturing discipline, whether for rapid prototyping, tooling, or, increasingly, production on demand, does not come without its own set of challenges, but deploying AM can also bring great advantages.

Can Stage 3 FSA Confirm Your Safety Instrumented System Is Ready for Operational Use?

The deliverable for a Stage 3 FSA includes a comprehensive report with a Stage 3 FSA checklist derived from a site visit and independent assessment. This report will present findings, including serious deficiencies, recommendations, and general observations.

Interrogating Quality Issues in Polymer 3D Printing

In production settings, maintaining quality control is essential for cost-effectiveness. Inaccurate or inconsistent 3D prints can lead to scrapped materials, increased production time, and costly rework.

Error-Proofing: The Key to Modern Manufacturing Success

For manufacturing engineers, a large part of the job is managing and eliminating risks. This process is called error-proofing, or poka-yoke in the industry.

Why you need to know where Smoke Tests fit in Your QMS

How did QA tell when a product failed its burn-in? The product stops working because its electronic circuits overheat and literally burn up. Everybody could tell where QA was located by the smoke rising above it from smoldering circuit boards.

Three layers of predictive maintenance - New horizons in a world of AI and Big Data

The key difference between preventive maintenance and predictive maintenance is that the latter means completing maintenance only when needed, as opposed to scheduled intervals.

The secret lives of manufacturing defects - How defects pass through the system undetected

Here Zohar Kantor, chief revenue officer at quality inspection pioneer QualiSense, traces how defects enter the manufacturing process and avoid detection.

Enhanced Quality Control and Post Processing for Metal 3D Printing

Metal 3D-printed parts can be produced at higher production rates with impeccable quality by implementing advanced quality control and post-processing techniques.

The Monetary Impact of Quality and Quality Management

Quality is not something that you can add into your product in the last step of your process. Quality is the outcome of all your processes and efforts.

Using Infrared to Ensure Package Seal Integrity

Using infrared inspection as part of a quality control program allows for inspecting all package seals in the production line. Companies can ensure package seal integrity, promote product quality, and elevate customer satisfaction by implementing package line inspection.

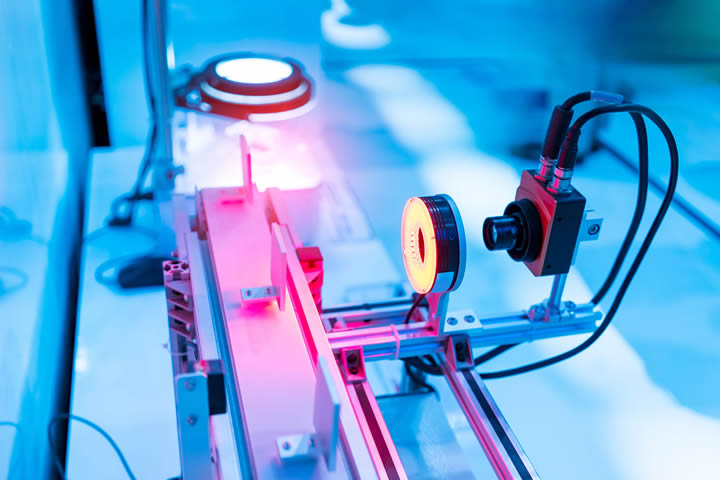

Do quality managers really want fully autonomous visual inspection?

Autonomous quality inspection solutions that are premised on the idea that the human user might make a mistake promise the highest level of automation. However, surely it is better to utilise the user.

Simplified CMM Inspection Provides a Flexible Approach to More Productive Quality Control

The simplified operator menu lists all the available inspection programs and the exact position the part should be placed on the machine table for inspection, giving operators the confidence to perform measurement tasks in just a few clicks.

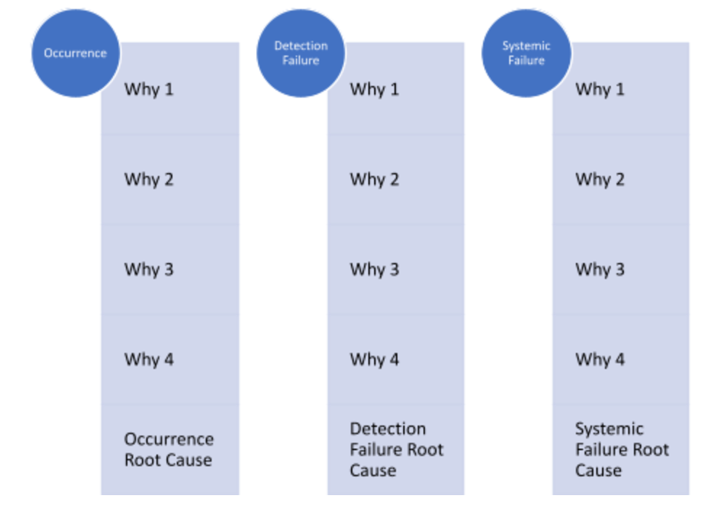

5x5 Why - a Better Way to Resolve Supplier Related Quality Concerns

From my experience, relational governance inevitably creates an atmosphere of loyalty and trust much more easily than one that is adversarial, focusing only on punitive actions when contractual agreements are not met.

Continuous and Exacting Measurements Deliver New Levels of Quality Control

Using continuous measurements reduces or even eliminates the production of faulty products and allows for consistent and repeatable production. This used to be an impossible task for small products.

When Products Fail

Spectacular failures tend to attract much attention. It is simple curiosity as to why it happened and why something was not done to prevent it. One such event was the engine fire on a Boeing 777 flight over Denver in February 2021.

Records 1 to 15 of 22

Featured Product

Super Air Knife Replaces Blowers & Saves Energy

Super Air Knife reduces compressed air usage & noise when compared to other blowoffs. The Super Air Knife offers a more efficient way to clean, dry or cool parts, webs or conveyors. It delivers a uniform sheet of laminar airflow across entire length.

https://exair.co/184_523

Manufacturing and Automation - Featured Company

Teledyne FLIR

Teledyne FLIR designs, develops, manufactures, markets, and distributes technologies that enhance perception and awareness. We bring innovative sensing solutions into daily life through our thermal imaging, visible-light imaging, video analytics, measurement and diagnostic, and advanced threat detection systems. Teledyne FLIR offers a diversified portfolio that serves a number of applications in government & defense, industrial, and commercial markets. Our products help first responders and military personnel protect and save lives, promote efficiency within the trades, and innovate consumer-facing technologies. Teledyne FLIR strives to strengthen public safety and well-being, increase energy and time efficiency, and contribute to healthy and intelligent communities.

.jpg)

.jpg)