How Aerospace Precision Can Modernize American Manufacturing

One of the biggest obstacles to modernization, he notes, is cultural rather than technical. The main barriers are organizational silos, he says. Design, production, and IT often operate separately, and without shared data, digital transformation stalls.

Closing Europe's aerospace production gap - EDM automation as part of the answer

EDM removes material using controlled electrical sparks between an electrode and the workpiece submerged in dielectric fluid. This makes it possible to cut extremely hard metals into complex shapes with micrometre accuracy.

3D Printing Produces Engine Covers To Accelerate Aircraft Maintenance

How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds.

Why 3D Metal Printing Is Key to the Future of Aerospace Engineering

The aerospace industry constantly pushes the boundaries of what's possible, and the demand for advanced manufacturing techniques has never been more critical. This pursuit of innovation has led to a significant shift toward 3D metal printing.

The Sky's the Limit: Additive Manufacturing in Aerospace Will Soar with Parts Certification

The introduction of a wide range of materials, including high-temperature materials, is enabling production of flightworthy parts capable of withstanding extreme conditions, like temperatures over 350F.

Relativity Space Maps Path to Terran R Production at Scale With Unveil of Stargate 4th Generation Metal 3D Printers

Relativity Space's Stargate 4th Generation 3D metal printers, capable of horizontally printing objects up to 120ft long and 24ft wide at as much as 12x faster than its predecessor.

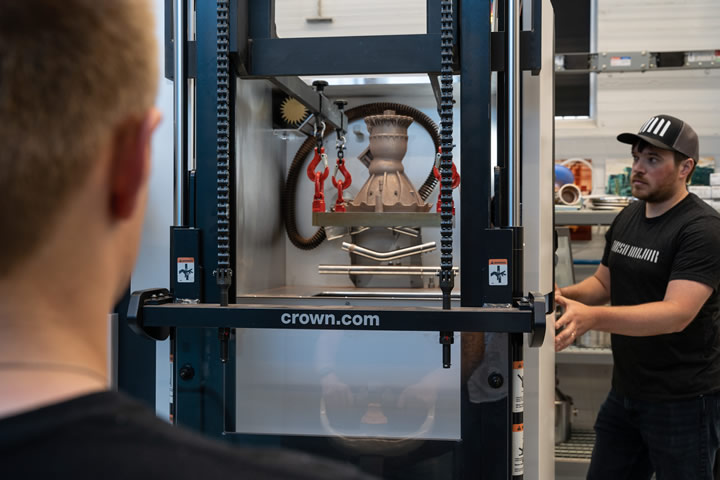

Rocket Propulsion Company's 3D-Printing Lab Delivers First Rocket Engine Components

Ursa Major's Advanced Manufacturing Lab in Youngstown, Ohio Cuts Time to Produce Rocket Engine Components from 6 Months to 1 Month

2021 Top Article - Additive in Space - Cost Reduction in Aerospace Through Additive Manufacturing

The elements needed for space travel do not have to meet the high launch requirements, but can be tailored precisely to the mission requirements. The process is being researched on parabolic flights in zero gravity - supported by a uEye CP industrial camera from IDS.

When Products Fail

Spectacular failures tend to attract much attention. It is simple curiosity as to why it happened and why something was not done to prevent it. One such event was the engine fire on a Boeing 777 flight over Denver in February 2021.

MAKING FASTER FLIGHT MAINTENANCE POSSIBLE

Satair, an Airbus services company, wanted to expedite aircraft maintenance through on-demand tools manufacturing. Fast Radius worked with Satair to deliver an innovative multi-process manufacturing solution that has the potential to transform the aerospace market.

ADDERE REDUCES THE PART COUNT IN LARGE SCALE ASSEMBLIES

"It's so rare that we get to show some of the capabilities we have, especially one that has gone through finish machining, says Scott Woida, President ADDere, "I think it gives a new perspective to what is possible with the technology."

Successful Mission of TuPOD, 3D Printed Innovative CubeSat

There is no doubt that 3D Printing is shaping our societies. Its future is evolving very fast and, although its impact on different sectors is still to be defined, many industries are leveraging 3D Printing technologies for their goals.

Success: 3D Bioprinter in Space Prints With Human Heart Cells

A 3D bioprinter privately owned by an American company has successfully printed with a large volume of human heart cells aboard the International Space Station (ISS) U.S. National Laboratory.

Automating Assessments in A&D for Improved Quality

Using digital twin and digital thread technology, A&D manufacturers can conduct automated assessments to analyze the performance of aircraft components - an advancement that has significant implications for the industry.

Building Optical Assemblies for Commercial Space Applications - Key Supplier Selection Criteria

The requirement for reliability and precision is especially the case when looking at space/earth imaging devices, which must be rugged, produce exceptional results, while at the same time being competitively priced.

Records 1 to 15 of 32

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Manufacturing and Automation - Featured Company

Fronius Perfect Welding

We aspire to produce more than just welding systems, which is why we are the innovation leader for arc welding and are constantly developing welding processes further. In addition to welding technology for robot applications, we offer solutions for manual gas shielded arc welding, for MIG/MAG, TIG, and MMA welding processes. We also implement automated, complete welding solutions tailored to customer requirements in the field of welding automation. After all, welding creates connections - between metals, between industries, and between people. Connected by the arc, by passion, by the beat of welding.

.jpg)