Additive & 3D Printing - Articles, Stories & Interviews

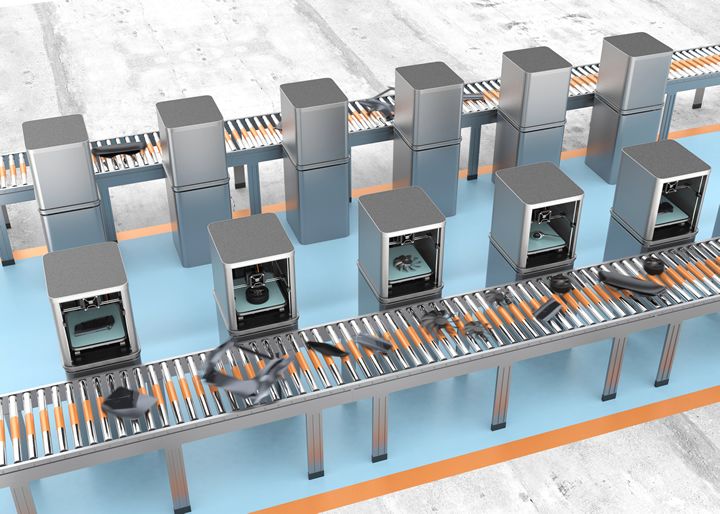

2025 Top Article - AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

2025 Top Article - How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

Closing Europe's aerospace production gap - EDM automation as part of the answer

EDM removes material using controlled electrical sparks between an electrode and the workpiece submerged in dielectric fluid. This makes it possible to cut extremely hard metals into complex shapes with micrometre accuracy.

Designing for Deviation in Additive Manufacturing

To truly realise the potential of AM, we need to embrace a new design philosophy, one that doesn't just work around variation, but works with it. At Metamorphic, we call this approach Designing for Deviation.

NewsFender's 3D Printed Ballistic Fender Charts a New Course in Maritime Defense

Discover how NewsFender's 3D printed customizable, eco-friendly fenders and boat parts are making waves in the maritime defense industry.

When Clean is the Key to Precision

Micro molded parts are often invisible to the naked eye, measured in millimeters or fractions of millimeters, with features that can be smaller than a human hair. In this context, a single dust particle can disrupt form, fit, or function.

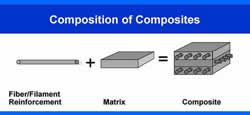

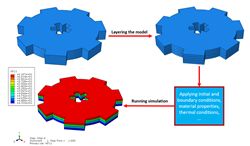

Comprehensive Guide to Composite Materials and Simulation

Composite simulation is crucial because it lets engineers explore designs, optimize performance, and spot failures digitally, saving tons of time and money compared to physical testing. It's challenging due to anisotropy, modeling delamination, and high computational cost.

Additive & 3D Printing - Featured Stories

From Heat to Shock: A Materials Playbook for Gigacasting Automation

.jpg)

Gigacasting automation is the most innovative pathway for creating inexpensive yet structurally sound technologies in some of the most intense industries on the planet.

How Miniaturisation is Reshaping Product Development

Products are shrinking, yet their functionality and complexity are growing exponentially. This shift is rewriting the rules of design, engineering, and manufacturing.

Basics of 3D Printing Simulation: Answering Key Questions

This article provides a comprehensive overview of additive manufacturing simulation, which involves virtually testing and optimizing the 3D printing process.

Additive & 3D Printing - News Headlines

Meshy Unveils AI Creative Lab at CES 2026, Turning AI-Generated 3D Creations into Physical Products With One Click

The leader in 3D generative AI, Meshy introduces the industry's first imagination-to-reality engine, bridging digital creativity and reality

A researcher's long quest leads to a smart composite breakthrough

Yu's team has used an advanced manufacturing technique called additive friction stir deposition to embed functional ceramic particles into metal. The result? A strong, defect-free material that can phase-shift under stress to dissipate energy and, unlike normally brittle ceramics, can be 3D-printed in bulk with full density in the as-printed state, opening up possibilities for practical applications in defense, infrastructure, aerospace, and even high-performance sporting equipment.

AMufacture to Host Industry Showcase Open Day Featuring HP Technology

AMufacture is throwing open the doors of its Portsmouth base for an Open House and Demo Day in collaboration with HP Additive Manufacturing Solutions in the new year.

Additive & 3D Printing - Featured Product

BigRep ONE: Large-Scale 3D Printing

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Additive & 3D Printing - Featured Company

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.