Twin transition: a path to the future or just another corporate buzzword?

Here, Johannes Wolf, Managing Director at automation supplier COPA-DATA Central Eastern Europe & Middle East (CEE/ME), explains why the green and digital twin transition is more than hype - and how we can turn it into measurable impact.

Indian Aircraft Manufacturing Company Raphe mPhibr Revolutionizes Unmanned Aerial Vehicle Innovation with Dassault Systèmes' 3DEXPERIENCE Platform

Dassault Systèmes' 3DEXPERIENCE platform helped Raphe mPhibr reduce prototype development time from years to three months. The 3DEXPERIENCE platform integrates design, simulation and collaboration, supporting in-house design and manufacturing

Digital Twins in the Supply Chain: A Pathway to Predictive Logistics and Lean Operations

This article describes not only what a digital twin is but how it works as a predictive and resilient backbone for contemporary supply chains. From demand planning to warehouse automation, the revolution of the digital twin has already arrived.

Updates on Technology in Engineering: Digital Twins and AI Reshaping Product Development

Industry leaders like Dassault Systemes, Siemens, PTC, and Omnix International are pushing the boundaries of virtual twin experiences, AI-driven development, and immersive digital environments. Here is a look at some of the exciting updates in digital twins and engineering

These Innovations in Telecommunications Are Elevating Manufacturing in 2025

From 5G to edge computing, innovations are reshaping how factories operate and redefining smart manufacturing's potential.

Leveraging the Virtual Twin Experience for Decarbonization in the Metals Industry

In this article, Prashanth Mysore, Senior Director for Strategic Business Development at DELMIA, explores how Virtual Twin technology can transform your business operations, whilst also addressing decarbonization.

How XR is Accelerating Digital Twin Technology for Global Machine Hardware Manufacturers

Extended Reality or 'XR' is an umbrella term for Virtual Reality (VR) and Augmented Reality (AR). While digital twin technology has always helped to bridge the gap between virtual and physical realms, XR extends its capabilities several steps further.

ADLINK's AI Edge Server Successfully Deployed in Smart Manufacturing, Driving AI Innovation and Digital Transformation

Through real-time data analysis and intelligent decision-making, enterprises can simulate and predict production processes in a virtual environment, identify and solve potential problems in advance, and accelerate the pace of digital transformation.

The Future of Manufacturing: How Digital Twins, 3D AI, Robotics Automation, and Immersive Reality Tech Are Modernizing Industries

The manufacturing sector today is being driven by rapid advancements in sophisticated technology. Among the most significant contributors to this modernization are Digital Twins, 3D AI, robotics automation, and immersive reality technologies.

The Evolution of MQTT: Empowering Industrial Automation for 25 Years and Beyond

In manufacturing and industrial automation, the evolution of communication protocols has been pivotal in shaping operational efficiency, predictive maintenance, and overall innovation. Among these, MQTT stands as a beacon of connectivity

Using AI to Fill Blind Spots and Revolutionize Manufacturing Processes

One of the biggest pain points in the manufacturing industry is that most processes are not instrumented, resulting in upwards of 75% of digital blind spots. This lack of visibility on the shop floor leaves manufacturers without a complete data picture.

Navigating the future of metalworking in 2024 - Manufacturers turn to digitalised CNC machining and interconnected smart factories

Tezmaksan Robot Technologies looks at the key trends in manufacturing and explores why manufactures should embrace transformative technologies with user-friendly interface and adaptability to keep up with the evolving needs of the metalworking industry.

NVIDIA and Hexagon Deliver Suite of Solutions for Accelerating Industrial Digitalization

Sweden's Hexagon AB is connecting its reality capture and manufacturing platforms to NVIDIA Omniverse so enterprises can more easily develop and deploy digital twin applications.

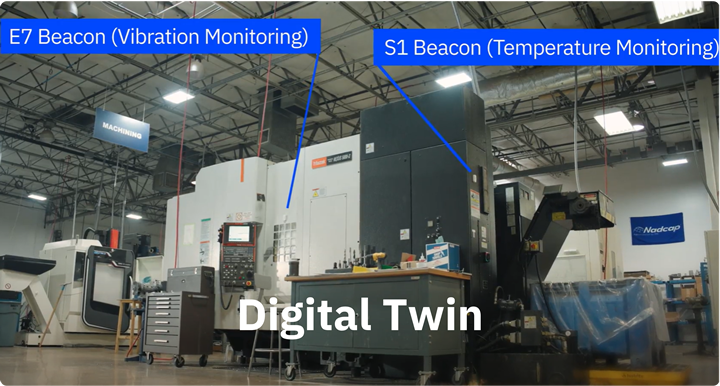

What is Digital Twin technology and why is it important for manufacturers?

Whilst uptake in smaller manufacturing firms has been slower, those within the sector are slowly starting to see the value that digital twin technology can bring, no matter the size of the business.

Optimizing the Manufacturing Supply Chain With 7 Tech-Forward Solutions

Every manufacturing operation needs an efficient and resilient supply chain. Stock shortages, shipping delays and similar disruptions can prolong production, raise costs and impact customer satisfaction, so manufacturers must prevent them as much as possible.

Records 1 to 15 of 24

Featured Product

Quality assurance in the manufacturing industry

Efficiency and precision with CSP software. In the highly competitive world of manufacturing, quality assurance is a critical factor for success. CSP offers you state-of-the-art software solutions specifically designed to ensure the highest standards of quality assurance in the manufacturing industry.

Manufacturing and Automation - Featured Company

ResinDek / Cornerstone Specialty Wood Products

At Cornerstone Specialty Wood Products®, we know and understand the importance of having the right flooring product for the right application. That's why we offer a variety of ResinDek panels in different thicknesses, densities, and with different surface finishes. Since 1994, ResinDek flooring panels have been installed in distribution centers, warehouses, manufacturing plants, and cold storage facilities for major corporations worldwide. The intent of Cornerstone Specialty Wood Products then and now is "We don't just make better mezzanine floors"¦We make mezzanine floors better". We strive to provide solutions that improve the ergonomics in work environments, reduce environmental impacts, and bring significant value to the professionals in many different industries.

.jpg)

.jpg)

.jpg)