The Library of Machine Malfunctions and Changing the Factory-Worker Relationship

The goal from day one was clear: build the definitive source of industrial reliability knowledge, and open it up to empower teams everywhere to shift from reactive troubleshooting to proactive control.

The Importance of Preventive Maintenance in Modern Warehouse Operations

This piece explores the framework of a comprehensive preventive maintenance strategy and how it supports a future-proof, efficient warehouse.

Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

Control System Migrations | Part 6 | Monitoring, Change Management, & Reporting

Effective project monitoring, proactive change management, and thorough reporting are keys to successful control system migrations. When executed properly, these processes provide significant stress relief, enabling project teams to maintain control

Advances in Preventive Maintenance Are Refining the Manufacturing Supply Chain in 2025

The need for innovative care and repair technologies grows as uptime and reliability become larger concerns. Recognizing which solutions offer the greatest potential for a facility is the first step to optimizing machinery throughout the supply chain in 2025.

7 Emerging Solutions for Reduced Manufacturing Downtime in 2025

Manufacturers hoping to reduce downtime more effectively in 2025 should pay attention to several emerging trends. Here are seven such technologies and strategies for greater uptime this year and beyond.

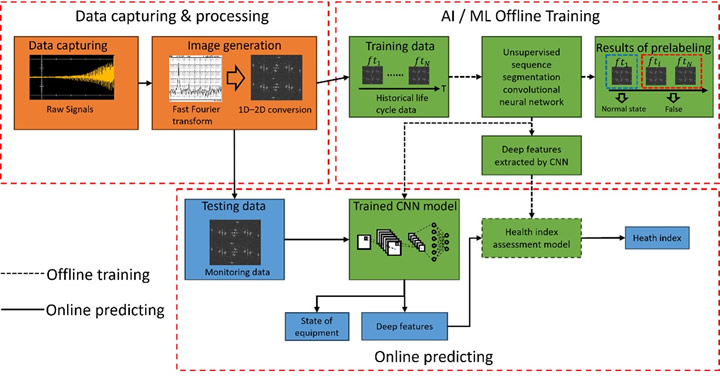

Machine Learning Unlocks Predictive Maintenance for Manufacturer

With an accuracy rate of more than 99%, AI-aided predictive maintenance systems can greatly reduce costs and improve uptime for manufacturers.

Reliable Industrial Robots with AI - Enhancing Fail-Safe Operations with Predictive Maintenance

With industrial robots' hourly operating rate of $2500, the financial impact of their failure can escalate quickly. Thus, it is crucial to avoid such technical disruptions in operations, whether it involves one singular robotic arm or several hundred industrial robots.

Proactive Maintenance: The Key to Reducing Unscheduled Downtime

Thermal imaging, also known as Thermography is a powerful tool for preventative maintenance in manufacturing. It involves using infrared cameras to detect heat patterns and anomalies in equipment

Three Ways AI Improves Maintenance Operations for Manufacturers

AI-driven maintenance decision intelligence tools give teams an unparalleled level of efficiency and insight, automating the integration of varied data sets and surfacing insights across your maintenance operations technology stack.

The Benefits of Predictive Maintenance Capabilities in Energy Management Systems for Industrial Facilities

Future trends in predictive maintenance focus on leveraging AI and machine learning to improve system accuracy and efficiency, and integrating IIoT for enhanced connectivity and data exchange in smart factories.

Beyond Noise: The 5 Benefits of Acoustic and Vibration Analysis

If we know the good behavior of a stationary random vibration, we can analyze and understand the random vibrations of a rotary machine that is wearing down over time and predict its failure.

Minimizing Unplanned Downtime: Strategies for Maximizing Productivity in Your Plant

By leveraging robust downtime tracking and analysis strategies, you can pave the way for preventative measures that detect and address potential defects in equipment promptly to protect production efficiency and safety.

Three layers of predictive maintenance - New horizons in a world of AI and Big Data

The key difference between preventive maintenance and predictive maintenance is that the latter means completing maintenance only when needed, as opposed to scheduled intervals.

ABB survey reveals unplanned downtime costs $103,000 per hour

It emphasizes the importance of effective maintenance strategies and service partnerships. 92% of respondents are interested in how outcome-based maintenance agreements can boost business success

Records 1 to 15 of 34

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Manufacturing and Automation - Featured Company

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)