Can Stage 3 FSA Confirm Your Safety Instrumented System Is Ready for Operational Use?

The deliverable for a Stage 3 FSA includes a comprehensive report with a Stage 3 FSA checklist derived from a site visit and independent assessment. This report will present findings, including serious deficiencies, recommendations, and general observations.

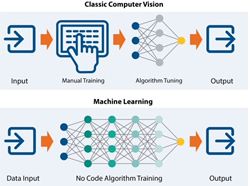

Error-Proofing: The Key to Modern Manufacturing Success

For manufacturing engineers, a large part of the job is managing and eliminating risks. This process is called error-proofing, or poka-yoke in the industry.

How Ethernet Cameras Are Making a Comeback with New, Powerful Features

In this blog, you'll get expert insights about the role of Ethernet cameras in embedded vision, their challenges, and the exciting features that continue to make PoE technology extremely valuable.

Making the case for Augmented Reality

The market size for AR applications was estimated to be $15.2B in 2021 and growing to over $90B by 2028. This shows clearly that companies are investing heavily in this transformative technology but why is it such a key innovation and how can you make best use of it?

2021 Top Article - Quality in the Era of COVID-19

Every day in 2020 has been somewhat of a surprise, but probably the biggest surprise of all has been how well manufacturers and quality teams have navigated all of the new rules, restrictions, PPE requirements and product mix changes that emerged.

AI for End-to-End Quality

Artificial intelligence (AI) is gaining favor as a solution for quality problems, but many manufacturers struggle with the perceived cost and complexity of implementing new technology.

Designing Zero Defect Manufacturing Systems Post-Pandemic

In the time of lean manufacturing where almost no company is fully vertically integrated, companies simply cannot have defective parts show up at their doorstep or build in lag time to allow for additional inspections that could have otherwise been avoided.

Readers Choice 2020: Quality 4.0: The 3 Most Important Technologies for Manufacturers

This article will explain the three technologies, that, based on Boston Consulting Group's Quality 4.0 study - will be deployed by most manufacturers who are planning to improve their quality management.

Modular Cubes with Modular Connection System for Smart Factory

KOSF's key project are the Smart Cubes, which are modular blocks that perform a dedicated task in the automation process, e.g. quality inspection, testing cells, robotic assembly, packaging and many more.

Three Ways Autonomous Machine Vision (AMV) Benefits Plastic Injection Moulding

Plastic injection moulding is a difficult application for machine vision. The highly reflective surface of plastics is hard to illuminate, and the fact that the same production line can create items of different colours and shapes is problematic for traditional solutions.

The Real World Quality Journey

Quality 4.0 blends technology with traditional methods of quality, in order to help manufacturers achieve operational excellence. It leverages technology to collect data enterprise-wide to provide visibility into the complete product lifecycle and manage workflows.

New Laser Welding Process Monitoring Systems Ensure Data Traceability

Ensuring seamless laser weld quality control and manufacturing traceability, the monitors catch weld errors as they occur in real time, instead of reacting to defects downstream. This ultimately increases yield, improves quality, saves labor, and increases savings.

Records 1 to 12 of 12

Featured Product

OnLogic Karbon 520 Series of Scalable Rugged Computers

The OnLogic Karbon 520 Series of rugged computers is purpose-built to deliver unwavering performance and reliability in the face of extreme temperatures, vibration, and dynamic power conditions. Powered by the latest Intel® Core™ Ultra processors and validated by MIL-STD-810H testing, the Karbon 520 Series makes it possible to deploy dependable computing for AI at the edge, advanced automation, or critical remote and in-vehicle applications in even the most challenging environments.

Manufacturing and Automation - Featured Company

MRPeasy

MRPeasy is a seriously powerful and easy to use ERP software for small manufacturers that gives you everything you need to manage your manufacturing and distribution processes. Integrating sales, procurement, inventory, production, finances, and your team, it provides you with an accurate real-time overview of your operations.

MRPeasy is trusted by 2000+ small manufacturers worldwide, 700+ of which are based in the US and Canada. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries.

Try for free, no credit card needed.

.jpg)

.jpg)