9 Evidence-Backed Predictions for the Next Decade of Auto Part Manufacturing

How Real-Time Manufacturing Operations Drive Competitive Advantage in Volatile Markets

How to Employ AI in Manufacturing Sales

When Clean is the Key to Precision

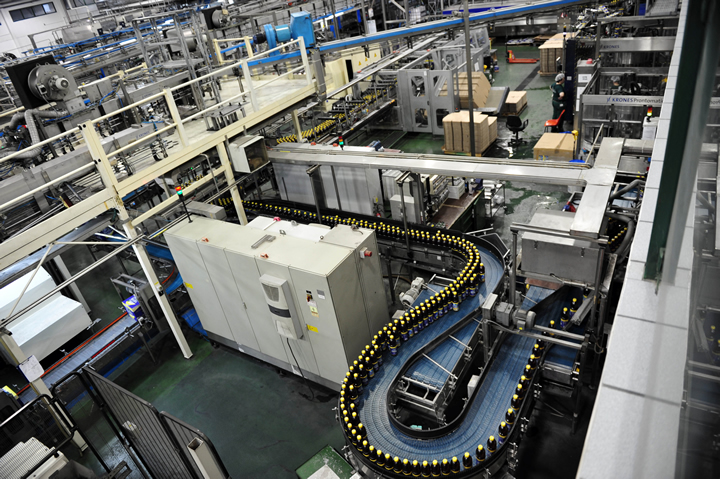

"Building for the Surge: How to Prepare Your Factory Storage for Times of Peak Demand"

Why Manufacturers Must Balance Proactive Cybersecurity with Verified Recovery

From Heat to Shock: A Materials Playbook for Gigacasting Automation

The Data Imperative for Smart Microfactories: Enabling Real-Time Agility and Resilience

Understanding End-to-End Configuration: A Primer

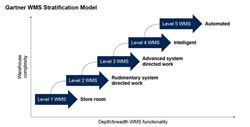

How Gartners 10 Dimensions of Warehouse Complexity can Transform your WMS Strategy

Unlocking the Benefits of a Data-Driven Manufacturing Supply Chain

Top 5 AI-Powered Capabilities to Look for in a WMS Vendor

Beyond Automation: How Software is Redefining Industrial Machinery

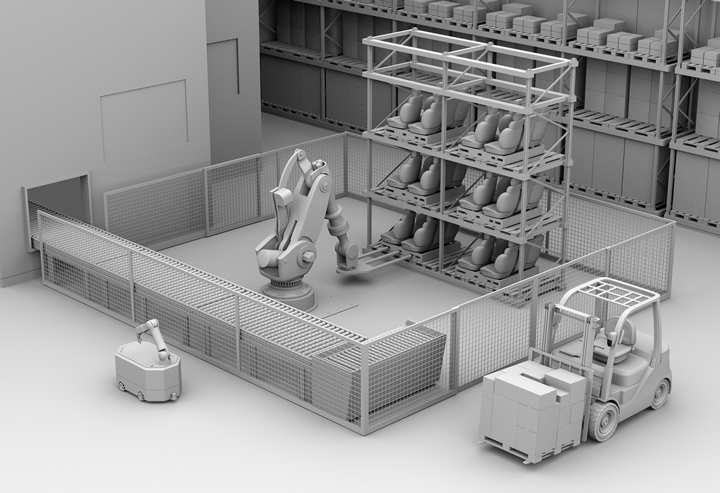

4 Robotic Finishing Techniques for High-Precision Manufacturing Applications

Adaptive Ventilation Is Creating Healthier, More Efficient Manufacturing Spaces

Records 16 to 30 of 1286

First | Previous | Next | Last

Featured Product

Datanomix Production Monitoring

Manufacturing and Automation - Featured Company

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)