How private 5G empowers manufacturers to maximize AI use cases

While Wi-Fi networks have historically met the basic wireless connectivity needs of some manufacturing operations, they increasingly fall short in more complex, high-demand industrial environments.

Energy-Efficient Manufacturing 4.0: Integrating Smart Drives, LED Displays, and IoT for Sustainable Factories

Energy efficiency in manufacturing means producing the same or higher output while consuming less energy. It is measured by key metrics such as energy intensity (kWh per unit produced) and power utilization rate.

Why Manufacturers Must Rebuild Their Factories Around the Buyer

Today's generation of buyers expects products built to fit their needs, transparent pricing, reliable delivery, and ongoing support that extends beyond the initial sale.

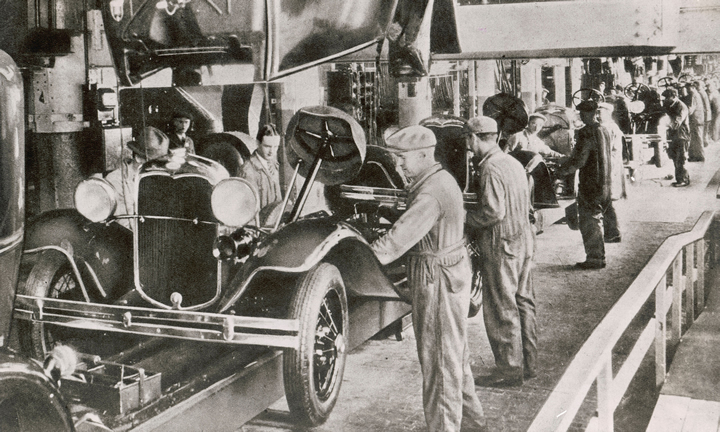

The Next Industrial Epoch is Here: Why Acting Now is a Strategic Imperative for Manufacturers

The convergence of technological maturity, proven financial returns, and a strategic need for resilient domestic production has created a generational opportunity, and the window to act is now.

How to Implement Zero Trust in a Smart Factory

Zero trust offers a strategic way to secure operations, boost efficiency and support sustainability. Leaders can gradually build a secure, scalable foundation by starting with asset mapping and small pilots like MFA and IAM.

From Legacy to Leading: How Manufacturers Can Bridge the Integration Gap

Despite big bets on AI, IoT and cloud platforms, many manufacturers are stuck at the starting line. Why? Because they're trying to race ahead while dragging decades-old systems behind them - and, those systems won't talk to each other.

Outlook for manufacturing to 2028

Technological advancements, consumer demand and global markets have always had the power to change the manufacturing industry, and in the coming years it is inevitable that we will see some big changes.

Why the U.S. is Poised to Lead a New Era of Manufacturing

Critics argue that high labor costs in the U.S. make it difficult for manufacturers to compete with countries offering cheaper wages. However, this perspective overlooks the strides the U.S. has made in workforce development and technological integration.

How manufacturers can apply smart buildings technologies to decarbonize operations

Gianluca Cassanova at ABB Electrification's Smart Buildings, explains how the application of smart buildings technologies can help multiple industries close the gap on sustainable manufacturing, the circular economy and the goal of zero waste to landfill.

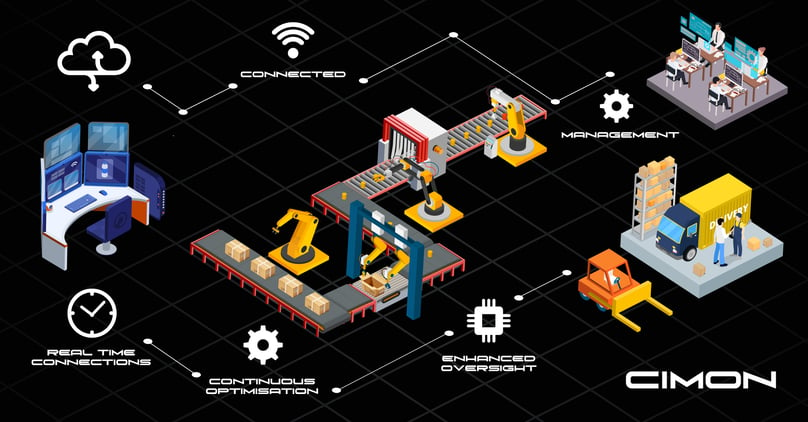

Smart Factories: A Digital Native's Guide

The way we leverage technology in a manufacturing environment is vastly different from one where most workers are seated in front of a computer all day. The established processes and daily challenges faced by plant managers are worlds apart from the digital realm of IT.

Factories of the future - What will manufacturing facilities look like in 2044

The landscape of manufacturing is set to evolve dramatically over the next two decades, as cutting-edge technologies redefine the way we produce goods. To envision what the future may look like, we do not need to rely solely on idle speculation.

Don't let delayed ROI delay your investment in smart connected products

Smart connected products can unlock new ways to generate revenue and cost efficiencies. While the payoff may be years away, companies need to invest today to remain not just competitive, but relevant.

The Role of Industrial PCs (IPCs) In Today's Smart Factories

The harsh conditions of factories such as extreme vibrations that may cause screens to crack, drastic changes in temperature and humidity levels, and physical debris have shown us that standard computing devices simply fall short in industrial environments.

Avoiding the Pitfalls: The Biggest Mistakes Manufacturers Make When Creating a Smart Factory

In this article, I will delve into the most common errors manufacturers make when working to create a smart factory, along with advice on how to prevent these mistakes.

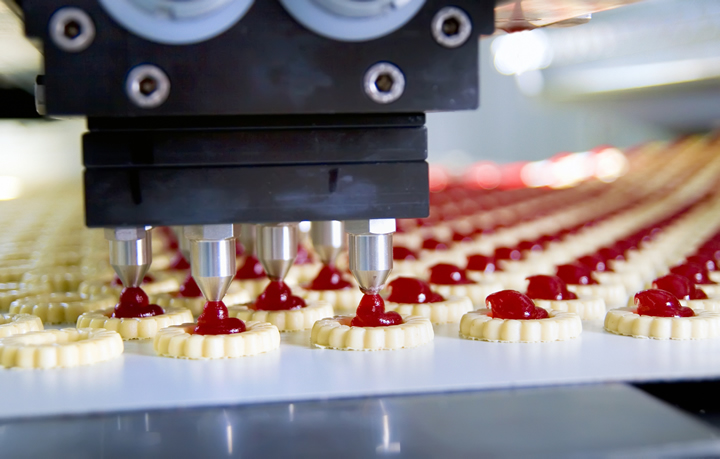

Why Manufacturers Should be All-in on Automation

Over the next five years, it's estimated that 25% of industrial spending will go toward automation. This spending will impact everything from logistics to retail to auto manufacturing and is expected to help improve several areas, including speed, safety, and product quality.

Records 1 to 15 of 157

Featured Product

MRPeasy - ERP for Small Manufacturers That Delivers Results

Always know what you have in stock and what you'll need to fulfill orders. Never forget to order parts on time or fail to notice a late delivery from your vendor. Easily create manufacturing orders and schedule them automatically according to resource availability or delivery deadline. Generate accurate cost and lead time estimates and provide customers with quick quotes. Receive notifications when orders are late or inventory levels reach a critical point. Ensure seamless communication between sales, production, warehousing, procurement, administration, and finance. Integrate with popular accounting, CRM, and e-commerce apps. MRPeasy is an ERP software for small manufacturers that gives you all that and more. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries. Try for free, no credit card needed.

Manufacturing and Automation - Featured Company

OnLogic

OnLogic is a global industrial computer manufacturer who designs highly-configurable, solution-focused computers engineered for reliability at the IoT edge. Their systems operate in the world's harshest environments, empowering customers to solve their most complex computing challenges, no matter their industry. OnLogic has helped more than 70,000 customers worldwide advance their ideas with computers that are designed to last, built to order and delivered in days.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)