The harsh conditions of factories such as extreme vibrations that may cause screens to crack, drastic changes in temperature and humidity levels, and physical debris have shown us that standard computing devices simply fall short in industrial environments.

The Role of Industrial PCs (IPCs) In Today's Smart Factories

Article from | CIMON

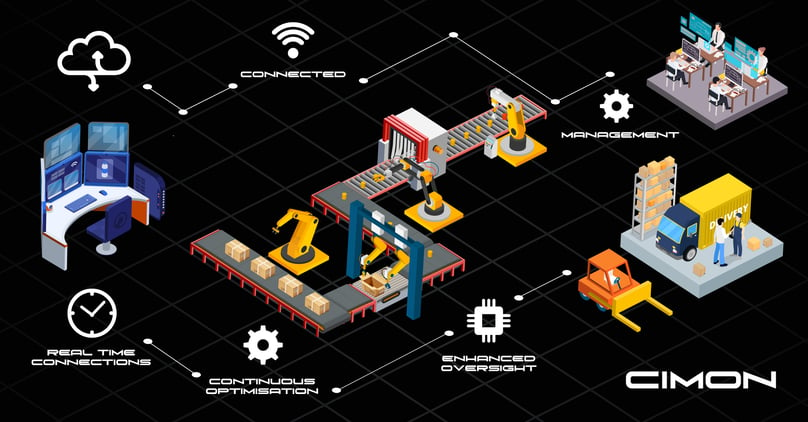

Factories today have been redesigned and equipped with technology to maximize production and minimize costs. Thanks to advances in Industrial Internet of Things (IIoT) technology and data analysis, smart factories have not only emerged but have become the industry standard. Smart factories emphasize increased efficiency and reduced labor and overhead costs using automation, resulting in greater total output, improved product quality, and higher levels of customer satisfaction.

Why Industrial PCs (IPCs) Are Necessary For Today's Smart Factories

The harsh conditions of factories such as extreme vibrations that may cause screens to crack, drastic changes in temperature and humidity levels, and physical debris have shown us that standard computing devices simply fall short in industrial environments. This is where Industrial PCs (IPCs) come into play.

IPCs have proven to be a superior fit in the increasingly complex environment of smart factories, standing out for several key features. Their rugged construction ensures that they can withstand the harsh conditions often found in industrial settings. Unlike traditional computers, IPCs employ fanless cooling systems, eliminating the need for vents or other moving parts. This design not only enhances their durability but also allows them to handle extreme temperatures and humidity, which are common in manufacturing facilities. The ability of IPCs to endure such demanding conditions makes them an essential component in modern smart factories, contributing to efficiency and reliability in industrial processes.

Roles That IPCs Can Play In Smart Factories

Temperature Control Within Factories

While smart factories are the future, most of today's manufacturing sites require retrofitting to incorporate IPCs. IPCs are playing an essential role in the modernization of existing manufacturing facilities, especially when it comes to climate control sensors. Through temperature and humidity control, IPCs can enable intelligent climate management within the factory. This may involve turning cooling or heating systems on and off after hours or triggering sensors to reduce humidity levels when necessary, allowing for more effective regulation of the factory floor. By using IPCs to manage these factors, smart factories can achieve lower total energy consumption and cost, making them more sustainable and profitable.

Inventory Management

Inventory Management is another vital area where IPCs can be used in smart factories. Poor inventory control can wreak havoc on any business, especially in manufacturing where precise coordination is essential. By employing IPCs, smart factories can leverage advanced data collection techniques to streamline inventory management. Items in inventory can be scanned, and the data can be stored and accessed through an Industrial PC. This digital management approach allows for real-time tracking and responsiveness, ensuring that inventory levels are maintained accurately, which is crucial for seamless production and profitability.

Minimizing Bottlenecks In Production With Preventative Maintenance

IPCs have the power to address one of the manufacturing industry's most pressing concerns: production bottlenecks. Billions of dollars are lost every year due to factory slowdowns. Before the advent of smart factories and IPCs, maintenance workers and supervisors had little means of anticipating or preventing these slowdowns. With the integration of IPCs, real-time data recording and visualization become possible, especially when combined with Human-Machine Interfaces (HMIs). This enables factory staff to closely monitor machinery, analyzing patterns that may signal the need for preventive maintenance. By acting proactively, factories can minimize slowdowns, increase overall efficiency, and make substantial savings in both time and money.

IPCs and Smart Factories Today

Smart factories are rapidly becoming the industry standard when it comes to manufacturing, with IPCs playing a crucial role in these changes. From energy control and inventory management to preventive maintenance and avoiding bottlenecks, the role of Industrial PCs is simply indispensable.

CIMON Automation offers IPCs suitable for any smart factory. Visit our website to learn more about how CIMON IPCs can transform your manufacturing operations, and take a step towards the future of smart factory technology with CIMON's top-of-the-line Industrial PCs.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product