Energy efficiency in manufacturing means producing the same or higher output while consuming less energy. It is measured by key metrics such as energy intensity (kWh per unit produced) and power utilization rate.

Article from | ADVANCED Motion Controls

Introduction

Energy-efficient manufacturing 4.0 integrates digital intelligence, automation, and data-driven systems to reduce energy waste and increase sustainability across production lines. In an era where industrial operations account for nearly 30% of global energy consumption, efficiency is no longer just a cost-saving strategy; it's a competitive advantage. Factories are becoming smarter, more connected, and more sustainable through the fusion of technologies like smart drives, LED visualization, and IoT-enabled monitoring. These systems don't just automate, they optimize. They allow machines to "think," displays to "communicate," and networks to "predict." In this article, we'll explore how these technologies are reshaping modern manufacturing, from real-time energy analytics to self-adjusting production systems designed for a cleaner industrial future.

What Does Energy Efficiency Mean in Manufacturing?

Energy efficiency in manufacturing means producing the same or higher output while consuming less energy. It is measured by key metrics such as energy intensity (kWh per unit produced) and power utilization rate. Efficient systems aim to reduce waste at every stage, including machine operation, heating, cooling, and logistics. When efficiency is maximized, manufacturers achieve greater profitability and environmental performance simultaneously.

Common indicators of energy efficiency include:

-

Power consumption per production unit

-

Utilization rate of machines and equipment

-

Ratio of energy input to productive output

-

Frequency of idle energy loss

These metrics help facilities evaluate where optimization opportunities lie, especially when integrated with smart, connected technologies.

What Is Manufacturing 4.0 and How Does It Transform Energy Management?

Manufacturing 4.0 refers to the digital transformation of industrial processes through automation, real-time data, and intelligent connectivity. It changes energy management by enabling manufacturers to track and control power consumption across every device and system on the shop floor. Through machine-to-machine communication, AI-driven insights, and IoT networks, energy use becomes transparent and manageable.

The four core pillars of Manufacturing 4.0 that support sustainability are:

-

Automation: Reduces manual error and energy-intensive inefficiencies

-

Connectivity: Links all machines for synchronized energy flow

-

Intelligence: Uses data analytics to forecast demand and optimize power usage

-

Adaptability: Adjusts production rates dynamically to prevent overconsumption

With these pillars in place, energy no longer disappears unnoticed; it's measured, analyzed, and optimized in real time.

How Do Smart Drives Contribute to Energy-Efficient Manufacturing?

Smart drives are electronic systems that control motor speed and torque using real-time feedback and adaptive algorithms. They are essential for improving energy efficiency because motors use most of the energy consumed in manufacturing. By adjusting motor behavior to match actual demand, smart drives reduce waste, lower heat output, and extend equipment lifespan. In the context of Manufacturing 4.0, these drives communicate with sensors and IoT platforms to continuously fine-tune performance.

Key Advantages of Using Smart Drives in Industry 4.0

Smart drives provide multiple energy and performance advantages.

There are five main benefits:

-

Reduce power loss by ensuring motors only run at required speeds

-

Enable predictive maintenance through built-in data analytics

-

Improve process stability by maintaining precise torque control

-

Enhance automation compatibility for synchronized production systems

-

Lower operational costs by extending motor life and reducing electricity usage

When paired with intelligent energy systems, they create self-regulating processes that continuously improve efficiency without human intervention.

Limitations of Smart Drives in Energy Optimization

While smart drives bring many benefits, they come with a few challenges.

The four main limitations are:

-

Increase upfront investment due to hardware and software costs

-

Require skilled integration for compatibility with legacy systems

-

May experience firmware limitations that restrict updates or custom features

-

Demand operator training to fully leverage advanced control features

Despite these obstacles, most manufacturers recover their investment through energy savings within 1 to 2 years.

How Do LED Displays Improve Factory Sustainability?

LED displays are electronic visualization systems that use light-emitting diodes to communicate critical information to operators and engineers. In manufacturing environments, they display performance metrics, energy usage, and safety alerts in real time. Their high brightness, long lifespan, and low energy demand make them perfect tools for sustainable factories. A well-designed LED system transforms data into visible insights, enabling faster decisions and reduced energy waste.

Integrating smart dashboards, such as Dynamo LED industrial visualisation systems, enables production teams to view power performance, temperature trends, and output data instantly. This visibility fosters a culture of awareness and proactive correction, preventing inefficiencies from escalating.

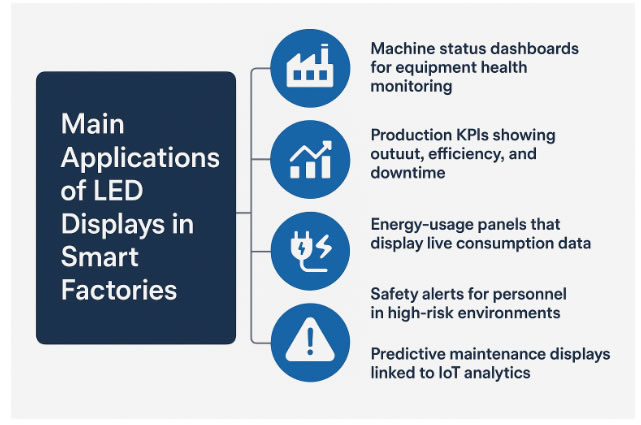

Main Applications of LED Displays in Smart Factories

LED visualization is used for a variety of manufacturing purposes.

Five key applications include:

-

Machine status dashboards for equipment health monitoring

-

Production KPIs showing output, efficiency, and downtime

-

Energy-usage panels that display live consumption data

-

Safety alerts for personnel in high-risk environments

-

Predictive maintenance displays linked to IoT analytics

By placing data at eye level, LED displays bridge the gap between energy consumption and operational decision-making.

Advantages of LED Displays Over Traditional Interfaces

LED displays outperform LCD and fluorescent signage in energy efficiency and clarity. They use less power, last longer, and offer superior brightness in industrial settings. Their durability and low maintenance further reduce long-term costs.

FeatureLED DisplaysLCD/Fluorescent Displays

Power Usage 40–60% lower, Higher

Lifespan Up to 100,000 hours 20,000–40,000 hours

Brightness High Moderate

Maintenance Cost Low High

These qualities make LEDs a cornerstone of visual communication in sustainable factories.

How Does IoT Enable Sustainable Manufacturing Operations?

The Internet of Things (IoT) is a network of interconnected devices that collect and exchange data. In manufacturing, IoT enables precise monitoring of machines, energy flows, and production conditions. By connecting smart drives, sensors, and visualization systems, IoT transforms isolated machines into intelligent energy ecosystems capable of self-optimization.

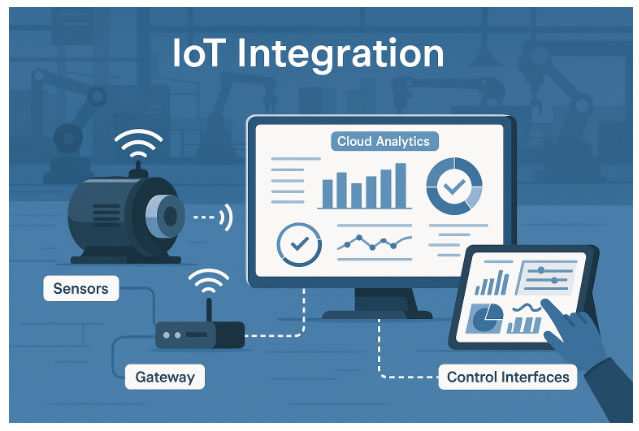

Core Components of an Industrial IoT Energy Network

An industrial IoT energy system is made up of four essential components:

-

Sensors: Measure voltage, current, and temperature in real time

-

Gateways: Aggregate sensor data and transmit it to analytics platforms

-

Cloud Analytics: Process and interpret the collected data for insights

-

Control Interfaces: Send back commands to optimize equipment performance

Each component plays a key role in keeping the energy loop closed and responsive.

Advantages of IoT-Driven Energy Monitoring

IoT-based monitoring provides significant advantages.

The five main ones are:

-

Predicts energy peaks and adjusts equipment loads automatically

-

Allows remote control of machinery and power distribution

-

Delivers real-time performance visibility across all systems

-

Integrates with ERP software for seamless operational planning

-

Improves regulatory compliance by logging energy consumption records

These benefits collectively make IoT the backbone of any sustainable manufacturing initiative.

Common Challenges in IoT Integration

Despite its potential, IoT integration in factories presents certain challenges.

Four common ones include:

-

Exposes systems to cybersecurity vulnerabilities if unprotected

-

Creates interoperability issues between different vendor technologies

-

Requires significant upfront investment for sensors and infrastructure

-

Generates massive data volumes that need specialized management tools

Manufacturers can overcome these issues through careful planning, network segmentation, and secure cloud deployment.

How to Integrate Smart Drives, LED Displays, and IoT Systems in a Factory

Creating an integrated, energy-efficient factory involves a structured approach. There are six main steps:

-

Conduct an energy audit to identify current inefficiencies.

-

Identify automation opportunities where smart drives can reduce consumption.

-

Select compatible drives and IoT sensors based on existing infrastructure.

-

Establish communication protocols like Modbus or OPC UA for connectivity.

-

Integrate visualization systems such as LED dashboards for real-time feedback.

-

Implement continuous optimization through data analytics and machine learning.

Each stage requires technical coordination, but the result is a self-improving ecosystem that balances energy efficiency with productivity.

What Are the Real-World Benefits of Integrating These Technologies?

The integration of smart drives, LED displays, and IoT creates measurable business outcomes.

The six main benefits are:

-

Reduce overall energy costs by 20–30%

-

Enhance production efficiency through automation and analytics

-

Lower machine downtime via predictive maintenance

-

Increase visibility across energy performance metrics

-

Enable sustainability tracking for corporate ESG reporting

-

Improve employee safety through real-time alerts and control

Manufacturers using these systems often see fast ROI, typically within two years of implementation.

How Much Does Energy-Efficient Manufacturing 4.0 Implementation Cost?

The cost of deploying these technologies depends on scale and complexity. On average, small facilities invest between $20,000 and $100,000, while large factories may spend up to $500,000.

Five main factors affect the cost:

-

Equipment such as smart drives, sensors, and displays

-

Software licensing for analytics platforms

-

Integration services required for system setup

-

Employee training to operate new technologies

-

Maintenance and support over time

Many manufacturers offset these expenses through energy savings and tax incentives for sustainability investments.

Case Studies: Examples of Energy-Efficient Smart Factories

Several companies have successfully transitioned to energy-efficient production. A European automotive supplier used IoT and smart drives to reduce energy use by 28% within 18 months. A US electronics plant employed Pheasant Energy energy-management for manufacturing solutions to optimize lighting and HVAC systems, achieving measurable savings. Similarly, an Asian precision-tool manufacturer combined LED visualization with IoT analytics, improving power utilization by 22%. These examples show how coordinated integration leads to practical, profitable sustainability.

What Are the Future Trends in Energy-Efficient Manufacturing 4.0?

The future of sustainable manufacturing is heading toward full digital autonomy. Artificial intelligence will optimize power distribution in real time, while digital twins will simulate energy outcomes before production begins. Wireless energy monitoring, green robotics, and renewable microgrids will soon become standard practice.

Four emerging trends to watch include:

-

AI-driven predictive energy control for adaptive performance

-

Digital twin simulations for resource planning

-

Decentralized microgrids integrating renewable power

-

Wireless sensors enabling flexible monitoring setups

Together, these innovations signal a shift toward net-zero manufacturing systems that learn and adapt.

Conclusion

Energy-efficient Manufacturing 4.0 represents the convergence of technology and responsibility. By combining smart drives, LED visualization, and IoT-based control, factories can operate intelligently while conserving resources. This synergy turns manufacturing from an energy-intensive process into a sustainable, data-informed ecosystem. As these tools evolve, manufacturers that embrace them early will not only reduce their carbon footprint but also gain long-term resilience and profitability in an increasingly competitive global landscape.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product