Transportation & Logistics Company Cuts Costs and Improves Asset Tracking with HiveMQ

As the shipping and logistics company scaled and especially during their peak season between Black Friday and Christmas, the number of devices, connections, and topics being created overwhelmed the broker, causing a lot of headaches.

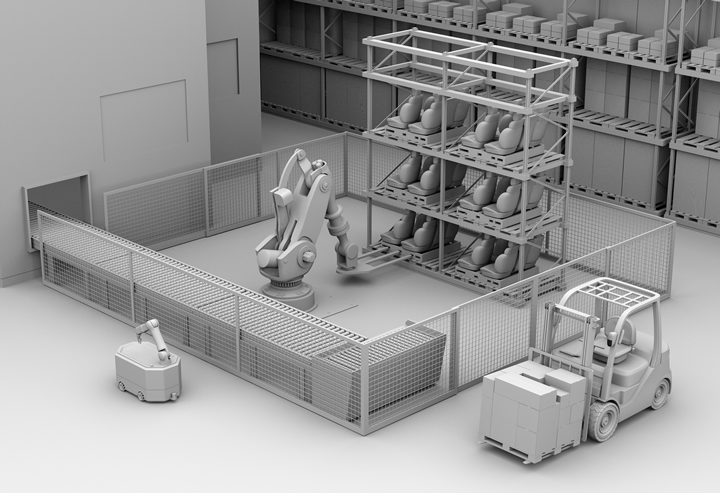

The Rise of Automation-as-a-Service (AaaS): Democratizing Warehouse Automation for Businesses of All Sizes

Automation-as-a-Service is a subscription-based solution that enables companies to integrate sophisticated automation tools into their operations without the hefty capital investment traditionally required for hardware, software, and maintenance.

5 Steps to Meet the Growing Demand for Automated Warehouses in 2025

Rising consumer expectations and supply chain complexities have placed a premium on efficiency, reliability, and safety. Here are five areas facility managers should prioritize to stay ahead of the curve.

Leveraging Voice-Directed Picking to Boost Warehouse Productivity

This innovative solution allows workers to receive audio instructions via headsets, keeping their hands and eyes free for picking tasks. Here is how you can use voice-directed picking to boost your warehouse's productivity.

Automation isn't a one-size-fits-all: 5 key considerations for your warehouse

From AI-vision systems revolutionizing inventory management to advanced depalletization solutions streamlining logistics, we'll explore five critical considerations that can make or break your journey toward integrating robotics into warehouse operations.

You Might Not Need Automation To Realize Greater Efficiency in Storage Operations

You could get the greatest benefits from additional automation if you first make sure your existing facilities support the highest productivity possible and the highest storage density feasible for your type of operation.

Steel King Selective Racking Systems to Bring New Efficiencies to North Pole Warehouse and Fulfillment Centers

A one-of-a-kind fulfillment center with a unique timeline for picking, packing, and magically delivering orders worldwide within a 12-hour timeframe, has selected Steel King for the new selective pallet racking system for its North Pole warehouse and distribution facilities.

PACK EXPO 2023 Product Preview

PACK EXPO 2023 takes place September 11th - 13th in Las Vegas, Nevada. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Tompkins Industries Reaches New Heights with its Vertical Lift Automation System

The automated vertical lift project kicked off in January 2022 and relied heavily on technical assistance from the team at PathGuide to incorporate the automated vertical lift into Latitude.

How Thoughtful Authentication Supports Your Sustainability Strategy

A sound sustainability strategy consists of continuous change, improvement and further development. It requires the continuous commitment of everyone, from management to trainees. And it is made up of many small things.

Embracing Automation Technologies to Optimise Just-in-Time Processes

As businesses' priorities evolve as a means to navigate today's challenging landscape, new processes, such as Just-in-Time (JIT), are being implemented to meet customer demands in the most efficient way.

Optimizing Warehouse Cold Storage Capacity and Longevity

Freezer and cooler storage pallet rack must withstand some of the greatest forklift abuse in warehouse material handling. This can be attributed to a number of factors including confined space, slick surfaces, and the cold temperatures.

How to Overcome Common Manufacturing Storage Challenges

Inventory issues can cause delays, limit productivity and generate unnecessary expenses. Manufacturing storage must improve if the industry is to become more efficient and resilient.

Three Ways to Improve Production Line Modularity

In today's competitive business environment, customization is key. Manufacturers in all industries are expected to provide a wide range of sizes, colors, styles and assortments, and they're finding that flexible manufacturing strategies are essential for staying competitive.

Electrostatic Dissipative Flooring vs. Anti-Static Flooring: Which Flooring is Right for Your Facility?

On the surface, anti-static sounds like the right choice. Anti-static means no static, right? Not quite. Read on to learn the key differences between anti-static flooring and electrostatic dissipative (ESD) flooring.

Records 1 to 15 of 24

Featured Product

NORD Delivers Powerful, Reliable Drive Solutions for Demanding Packaging Applications

When you need quality, flexibility and high efficiency, NORD has you covered with complete drive solutions for primary and secondary packaging, end-of-line packaging, and higher-level applications. NORD supports you through the entire life cycle of your drive systems with pre-sales engineering support, online tools, and a global service network. Drive systems for both vertically and horizontally networked technology with all the options for sensor incorporation and integration into the higher-level control system.

Manufacturing and Automation - Featured Company

Fronius Perfect Welding

We aspire to produce more than just welding systems, which is why we are the innovation leader for arc welding and are constantly developing welding processes further. In addition to welding technology for robot applications, we offer solutions for manual gas shielded arc welding, for MIG/MAG, TIG, and MMA welding processes. We also implement automated, complete welding solutions tailored to customer requirements in the field of welding automation. After all, welding creates connections - between metals, between industries, and between people. Connected by the arc, by passion, by the beat of welding.

.jpg)