How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

Conveyor systems are central to most warehouse operations, and without regular maintenance, downtime can prevent a warehouse from functioning which obviously has a large financial impact.

The Role of Conveyor Systems in Warehouse Logistics

In many warehouses there is still a reliance on manual labour and heavy lifting which can put workers at risk, as well as compromise on efficiency. This is where conveyor systems can completely revolutionise a warehouse operation.

Case Study from NORD DRIVESYSTEMS - A Better Conveyor

OCC Systems is making automotive assembly lines safer, more energy-efficient, easier to maintain, and less expensive to operate

Outbound Distribution Center

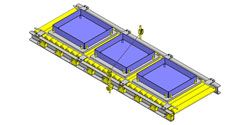

A brand-new outbound distribution facility needed to be equipped with a solution that would provide flexibility, improve productivity metrics, and meet expected quality and durability.

Automation Design Tips: Transferring with Rollers

As technology advances, components become smaller and more compact which requires specific automation techniques and maintenance. Transfer mechanisms require high versatility in its capabilities.

Can You Complete Your Project Without A Conveyor? The Pros and Cons

Can you accomplish the same goals with alternatives to conveyor? Possibly - but consider the opportunity cost. Lets explore some common misconceptions about conveyors, as well as some pros and cons of conveyor alternatives.

Trends in Conveyor Systems and Technology

Conveyors today are built to your specifications to improve efficiency and output of your production line. Theres no reason to settle for a conveyor thats being shoe-horned into your application

Beyond Conveyors: Conveying a Quality Solution

Designing the optimal material handling systems requires a deep understanding of the product, process, and challenges inherent in the manufacturing process.

Records 1 to 8 of 8

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Strain wave gearheads are ideal for use in applications requiring precision motion control and high torque transmission in a compact design. maxon strain wave gearheads are a specialized type of gearhead where precision and compact design are crucial. This type of gearhead is often used in applications in a confined space. With their advanced gear tooth design, maxon's strain wave gearheads provide high efficiency and good back drivability. Typical applications include:

Robotics, Aerospace, Medical technology and Optical systems

.

Manufacturing and Automation - Featured Company

NORD DRIVESYSTEMS

With four production facilities in the Midwest, on both coasts, and in the South, NORD is prepared to serve you with some of the shortest lead times in the industry. We house extensive component inventory, allowing us to assemble and ship 25% of all standard product orders same or next day!