Top Viewed Articles of 2023

ManufacturingTomorrow readers sought out Use Cases and Expert Insights to help guide them through the rapid changes happening throughout the industry. Here are the Top 4 Viewed articles from 2023.

Using Technology to Combat the Skilled Labor Shortage

Successful manufacturing companies are combatting the skilled labor shortage by investing in automation and software to complement their existing workforce, meet production requirements, and attract new talent.

Rittal's Urbana Campus a Pillar of U.S. Production

The 105-acre campus combines cutting-edge production with in-house engineering and modification services to increase efficiency across each touchpoint of the Rittal value chain.

Will 2020 Be the Year You Embrace Blockchain in Manufacturing?

Blockchain has proven an effective salve for the dwindling trust in today's supply chains. It enables a network-wide protocol that helps reduce "trust tax," or the costs of maintaining trust.

IDC Manufacturing Insights

It's clear that the manufacturing industry is transforming, and although automation may be reducing the need for some tasks, overall we do expect the manufacturing industry and employment to increase. 2018 is shaping up to be a good year for manufacturers.

Endress+Hauser's IIoT Vision

We currently offer telemetry devices and cloud based dashboards for our customers to collect process data from remote instrumentation and provide dashboards and operational efficiencies for supply chain management with our Supplycare service offering.

Japan is moving towards Neo-Industrial Manufacturing - Formation of Flexible Factory Partner Alliance

It appears Japanese factories, companies are looking beyond the IOT and or IOE; aiming to connect a variety of assets, e.g., machines, data, technologies, people, and organizations, as well as the existing industries and digital technologies, thereby bringing about the creation of new added value and the solutions to societal problems, bringing "Connected Industries" to fruition.

76 Percent of U.S. Workers Do Not Fear Automation, According to Randstad US

It is evident from our research that not only are workers not afraid of losing their jobs to automation, they are more than willing to retrain to leverage the efficiencies and benefits of artificial intelligence (AI) and robotics in the workplace

Power to the People: How Humans are Heading Back to the Factory Floor

In response to consumer demand and competitive pressures, product variation is on the rise. That variation changes the manufacturing calculus somewhat, as the required variation and corresponding complexity means that the ability to think critically and independently and adjust to changing circumstances is a priority.

US Manufacturing Needs a Makeover if We're Going to Close the Skill Gap

Manufacturing in the US isnt dying-Its getting smarter

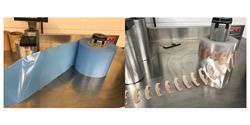

How to Increase Run Rates, Reduce Waste and Maximize Profitability

When you are looking for greater efficiency, higher run rates or less waste in your production, dont forget to look at the little things.

Is There a Tomorrow for Manufacturing in the United States?

Operators will soon be able to test and optimize the machine settings for the next product in line in the virtual world before they make the physical change-over.

Records 1 to 12 of 12

Featured Product

The Wire Association International (WAI), Inc.

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry. WAI hosts trade expositions, technical conferences, and educational programs.

Manufacturing and Automation - Featured Company

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.

.jpg)