Will 2020 Be the Year You Embrace Blockchain in Manufacturing?

Blockchain has proven an effective salve for the dwindling trust in today's supply chains. It enables a network-wide protocol that helps reduce "trust tax," or the costs of maintaining trust.

Value of Blockchain in Manufacturing

Blockchain has massive value in supply chains, and supply chains are the cornerstone of every manufacturing business. As such, increasing supply chain efficiency via the implementation of this technology will mean manufacturers can improve their material ordering process...

From Blockchain to Digital Twinning: Technologies That Can Revolutionize Business Models in Manufacturing

In its recent 'Exponential technologies in manufacturing' study, Deloitte observes that organisations from every industry now face mounting pressure to transform and make the shift from product-centric business models to capture other sources of value

Syncfab Presents Blockchain Solution With Sap, Boeing Panel at IOT Tech Expo 2018

Distributed ledgers allow authentication with just one single, unique entry for every part, user, or supplier, thereby increasing accuracy and cost savings when it comes to inventory management.

Chain, Chain, Chain

As consumers and participants in the supply chain demand greater transparency, blockchain has the potential to transform how information about a food product flows from farm to fork to ensure quality and safety by adding greater visibility and efficiency to the process.

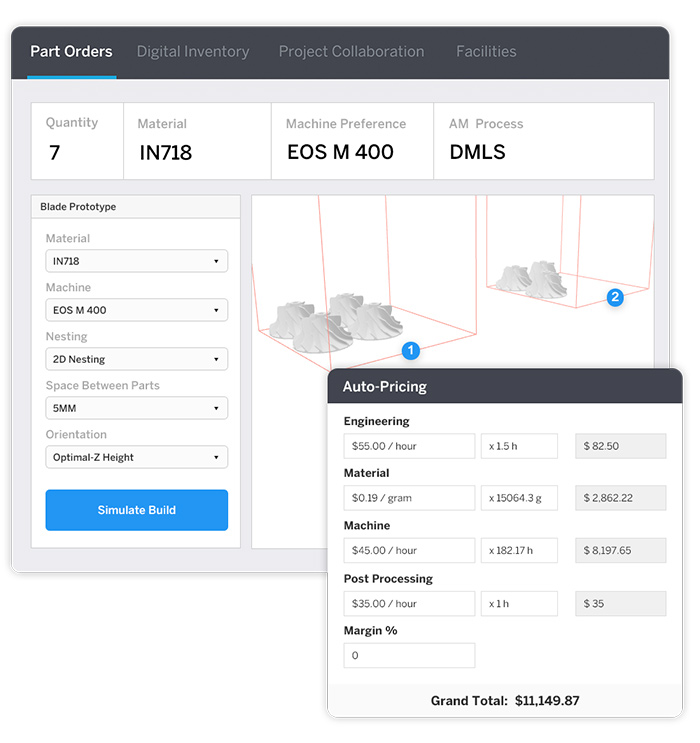

Using Blockchain Technology with 3D Printing Processes

3D digital manufacturing inherits several privacy and security-related challenges with multiple stake holders. Blockchain technology can be used for enabling data governance, data provenance, data auditability and data validation in 3D printing.

Startup Wants to Connect Thousands of 3D-printers in a Blockchain-based Network Hub

Kata Karath for CoinTelegraph: 3D-TOKEN, a project of the Italian Politronica Srl startup wants to integrate it with Blockchain technology to create a 'one of a kind glocal decentralized Just-In-Time Factory 4.0 matching the digital revolution of the 21st century.

How Blockchain will Transform the Enterprise

With machine-to-machine communication, how does one validate "identities" and secure data at such massive scale.

Records 1 to 8 of 8

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Strain wave gearheads are ideal for use in applications requiring precision motion control and high torque transmission in a compact design. maxon strain wave gearheads are a specialized type of gearhead where precision and compact design are crucial. This type of gearhead is often used in applications in a confined space. With their advanced gear tooth design, maxon's strain wave gearheads provide high efficiency and good back drivability. Typical applications include:

Robotics, Aerospace, Medical technology and Optical systems

.

Manufacturing and Automation - Featured Company

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.