Cross-functional collaboration isn't just helpful, it's the backbone of a smooth new product introduction. You can have the best design on paper, but if engineering, operations and supply chain aren't aligned from day one, you're setting yourself up for late-stage surprises.

Maximizing Operation Efficiency through Manufacturing Processes

Maximizing Operation Efficiency through Manufacturing Processes

Q&A with Avinash Dinka Erappa

Tell us about yourself and your expertise within manufacturing processes.

I started my career as a Trainee Engineer in a sugar factory, where I was responsible for operating a 24MW turbine as a DCS operator. That role gave me early exposure to the importance of reliability and process control. From there, I moved to a global cutting tool manufacturer, where I spent over five years in a hands-on production role. During that time, I led several continuous improvement projects using Lean Six Sigma principles- helping improve productivity, reduce cycle times, and even working directly with suppliers to improve their quality and output.

I started my career as a Trainee Engineer in a sugar factory, where I was responsible for operating a 24MW turbine as a DCS operator. That role gave me early exposure to the importance of reliability and process control. From there, I moved to a global cutting tool manufacturer, where I spent over five years in a hands-on production role. During that time, I led several continuous improvement projects using Lean Six Sigma principles- helping improve productivity, reduce cycle times, and even working directly with suppliers to improve their quality and output.

Later, I came to the U.S. to pursue my Master’s in Industrial Engineering at NJIT. During my studies, I interned with a food manufacturing company, which was a completely new world - especially with its strict hygiene and safety standards. That experience helped me see how process efficiency works in highly regulated environments.

After graduation, I joined the same company full-time as a Process and Project Engineer. There, I focused on eliminating bottlenecks and building tools using Excel and Power BI to make data more accessible for everyone - including dashboards that helped directors make quick decisions and tools that reduced reporting time by over 70%.

Right now, I work as an NSI/NPI Coordinator at an engine manufacturing company, helping launch new systems and products. I get to work across engineering, operations, and quality, which has really helped me see how collaboration can speed up implementation and reduce issues downstream.

Overall, my passion lies in solving real production problems using a mix of hands-on experience, data-driven tools, and team collaboration.

How can manufacturers effectively integrate continuous improvement principles with modern automation technologies to maximize operational efficiency?

In my experience, continuous improvement isn’t about one big fix, it’s about solving the small problems that interrupt flow daily. And that’s where automation becomes powerful. You can combine Lean thinking with smart, simple tools to reduce errors, save time, and make the system more transparent.

For example, in one of my roles, I implemented a poka-yoke solution after operators were manually entering CTQ data, which sometimes led to customer complaints. I automated the report using Excel formulas and Power Query to pull real-time data and eliminate manual input. This built trust with the quality team and reduced errors.

At another plant, I developed interactive dashboards using Power BI and Excel to give better visibility to production data. These dashboards helped teams react quickly to deviations instead of waiting for end-of-week reports.

More recently, I worked on a Python-based label printing program that generates QR-coded labels immediately after laser marking. This eliminated manual lookup, reduced delays, and improved traceability. Whether it’s Excel VBA, Power BI, HMI or Python, it’s about using the right tool for the problem, and always thinking about the operator experience.

To me, continuous improvement with automation is about keeping the process lean, smart, and operator-friendly, making sure technology supports people, not the other way around.

What are the most common bottlenecks you see in manufacturing processes today, and how can companies identify these pain points before they impact production?

From what I’ve seen, bottlenecks can appear anywhere, in equipment capability, process planning, scheduling, or even in how teams communicate.

At Kennametal, during a new product introduction, the demand was high and deadlines were tight. We brought in new machines to produce standard products, but the first bottleneck came from tool setup. Manual and hydraulic adapters caused frequent changeovers and idle time, so we switched to shrink-fit thermal adapters for better rigidity, tool life, and productivity. We standardized planning so operators avoided multiple setups, and changed the outsourcing process from weekly batches to daily minimum shipments. That kept the flow steady, doubled our monthly output from 700 to 1,400 units, and earned me the plant’s Best Productivity Award.

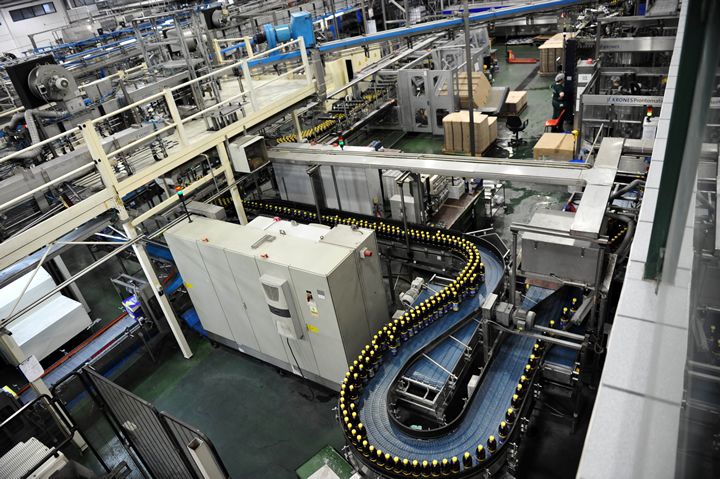

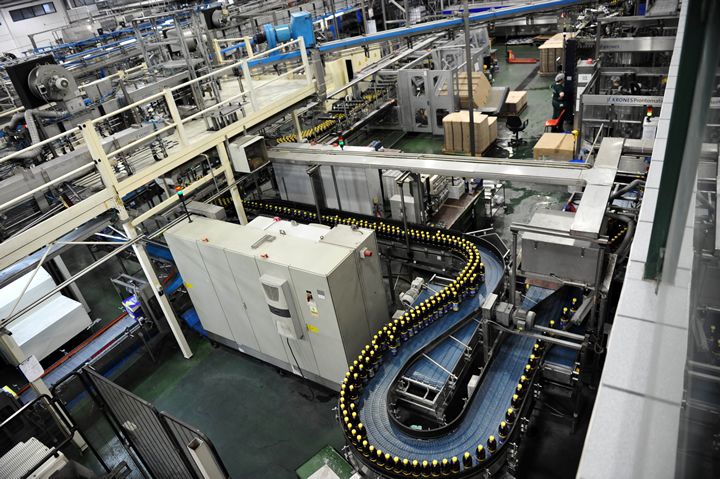

At Glanbia Nutritionals, belt stoppages were halting the entire line. I pulled six months of HMI data, reviewed 80+ tag IDs, and plotted patterns to see which faults repeated. Working with the maintenance and CAPEX teams, we fixed the underlying causes, cutting daily stoppages from 13,000 seconds to just 1,500 seconds.

At Caterpillar, a smaller but critical bottleneck was labeling after laser marking. Operators had to search and enter details manually, creating delays and errors. I built a Python program that generated labels with QR codes instantly after marking, removing the manual search step and improving both speed and accuracy.

To identify these issues before they impact production, you have to foresee the process. If possible, simulate it. Speak openly with every department involved and encourage transparent discussions. Know the process in detail, and map it with Value Stream Mapping, updating it whenever there’s a change. Look for points where manual intervention can be replaced with automation to reduce delays and human error. Above all, be proactive rather than reactive, a bottleneck prevented is always cheaper than a bottleneck fixed.

What role does cross-functional collaboration play in successful new product introduction, and how can engineering teams better align with operations?

Cross-functional collaboration isn’t just helpful, it’s the backbone of a smooth new product introduction. You can have the best design on paper, but if engineering, operations, quality, maintenance, and supply chain aren’t aligned from day one, you’re setting yourself up for late-stage surprises.

At Kennametal, I saw this firsthand when we were introducing new products with tight launch deadlines. We brought product engineering, tool room, and operators together early to standardize setups, which cut down on idle time and avoided constant retooling. It wasn’t just about the machine setup, it was about everyone knowing the plan and their role before production started.

At Glanbia, tackling belt stoppages was a team effort. Engineering alone couldn’t have solved it, we needed maintenance to fix root causes and the CAPEX team to back the upgrades. Because everyone had visibility into the problem and the impact, changes were supported and implemented quickly.

In my current Caterpillar work, introducing a new supplier’s product involves engineering, design, supply chain, quality, and CMM/product development from the very start. We hold weekly meetings with all departments to surface issues early and address them before moving to the next stage. This avoids rework, keeps timelines realistic, and ensures every department is ready before launch.

The key is transparency, early communication, and involving the right people before decisions are locked in. When teams align early, you replace last-minute firefighting with predictable, repeatable launches, and that’s when NPI really works.

How are global supply chain disruptions changing the way manufacturers approach process optimization and contingency planning?

In my experience, supply chain disruptions have forced manufacturers to think beyond traditional cost or lead-time optimization and focus more on resilience and flexibility.

At Caterpillar, we now run weekly alignment meetings involving engineering, design, supply chain, and quality teams before onboarding new suppliers. Even small material delays caused massive line stoppages in the past, so now we proactively plan for alternate sources and buffer stages earlier in the process.

When I worked at Kennametal, we outsourced to multiple suppliers to reduce lead times and cost, but constant switching created challenges in maintaining consistency. To keep customer satisfaction high, we had to sustain a 97% fill rate at distribution centers. That meant optimizing not just internal processes, but also tracking supplier performance, updating planning cycles, and flagging any potential breakdowns early.

At Glanbia Nutritionals, even though it was a food manufacturing setup, the impact of supply chain delays was just as critical. When one ingredient or packaging material was delayed, it stopped the line, so I worked on aligning production and procurement visibility to allow better planning. We developed dashboards to track delays and helped build in process flexibility for changeovers.

Across all these roles, I’ve learned that process optimization today is less about just speed or cost, and more about building resilience. Being able to foresee issues, create flexible workflows, and keep teams aligned is what makes operations future-proof.

What emerging technologies do you see having the biggest impact on manufacturing excellence in the next 3-5 years?

From what I’ve seen across different industries I’ve worked in, especially in places like Glanbia and now Caterpillar, the biggest impact will come from practical automation and operator-focused digital tools. It’s not just about the latest flashy tech; it’s about what actually solves problems on the floor.

For example, I worked on automating label generation using Python at Caterpillar, where we reduced manual searching and errors after laser marking. A simple automation, but huge in daily operations. At Glanbia, I built Power BI dashboards that pulled real-time data to track phage trends and streamline decision-making. These weren’t expensive systems, just smart, operator-friendly solutions.

I personally believe machine learning, predictive analytics, and IoT will keep growing, but only when they’re implemented in a way that’s scalable and easy to use. Same with augmented reality for training or maintenance, and HMI systems for visualizing downtime or trends, I didn’t build the HMI, but I worked closely with the team to drive changes based on insights from downtime patterns and operator feedback.

At the end of the day, technology should be a support system, not an overhead. If it takes too much training or adds layers of complexity, it defeats the purpose. I’ve always pushed for solutions that make life easier for the people running the line, that’s where real impact happens.

How can smaller manufacturers compete with larger operations by implementing strategic process improvements without massive capital investments?

In my experience, smaller manufacturers can absolutely compete if they approach operations strategically. During my time at Kennametal, I managed an outsourcing plant where we worked with multiple vendors, often small or mid-sized suppliers. One of the key challenges was meeting monthly demand targets for both standard and special products, while avoiding bottlenecks and delays at the warehouse and final processing stages.

We started by analyzing the entire supply flow. Instead of waiting for weekly shipments that caused pileups and end-of-month chaos, I worked with the suppliers to implement a system of daily deliveries. This required value stream mapping, better communication, and forecasting, not expensive equipment.

We also separated the planning for standard and special parts, which simplified scheduling and gave the operators clarity on priorities. These small changes made a big difference, we began seeing improvements in 2 months, and by the 5th month, the system had fully stabilized and was running smoothly.

For small manufacturers, the key isn’t big money, it’s visibility, planning, collaboration, and streamlining. With a proactive mindset and openness to tweak processes, even lean teams can scale their efficiency significantly.

Avinash Dinka Erappa is an Industrial Engineer with global experience leading process improvements, automation initiatives, and production optimization in manufacturing. Hw specializes in new product introduction (NPI) coordination and cross-functional engineering program management. He holds a Master's in Industrial Engineering from NJIT with expertise in continuous improvement methodologies and bridging engineering operations across global supply chains.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product