What is the process approach?

The process approach is a way of thinking about work: modeling it, improving it, and correcting errors. The reason everyone uses it is that it works. Describing your work as a process makes you more effective in many contexts.

Process and System Efficiency: You Can't Improve What You Don't Measure

KPIs are quantifiable metrics used to measure the success of a particular process or system. They are typically tied to specific objectives and goals and are used to track progress over time.

Flexible feeding for a smarter production line

Vibratory feeders are used to align and feed small products and parts during the assembly and production process using gravity and vibrations. They are a common element of many operations and an effective way of automating production lines.

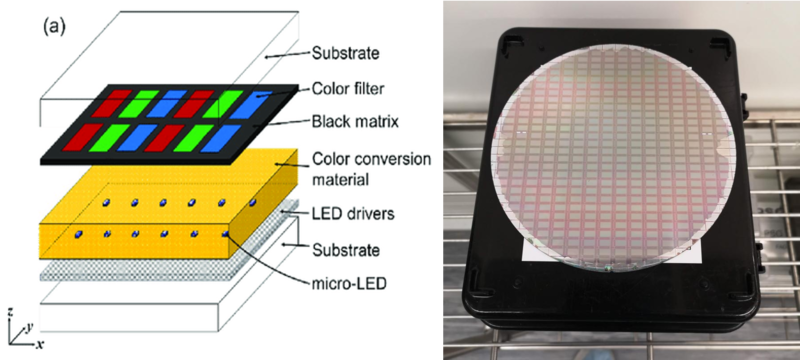

Progress in MicroLED Fabrication and Quality: Closing the Commercialization Gap

Establishing cost-effect fabrication processes for microLED displays has proven to be challenging, and manufacturers are still working to close the gap between promise and market reality.

7 Improvements to Manufacturing Processes - and How They Affect the Bottom Line

New technologies and processes must have a demonstrable impact on a company's bottom line to make a convincing argument for adoption. In that spirit, here are seven recent manufacturing process improvements and how they affect profits.

Readers Choice 2020: Impact of COVID-19 on the Process Manufacturing Industry; 2020

Read to know how the many process manufacturing businesses around the world impacted by COVID-19 can bounce back.

Advantages of Web-based ERP for the Process Manufacturing Industry

Cost-effective, easy to use, and quick to implement, web ERP software offer several functionalities and advantages to your process manufacturing businesses.

Ensure the Quality of Food through innovative Sieving solutions

Foodborne illness is the global threat to the world. Associations and government bodies have put up strict guidelines to follow in the processing line. Therefore, manufacturers are bound to use hygienic food processing equipment to meet the regulations.

Taking an Incremental, Multi-Stage Approach When Upgrading Aging DCS Systems

Addressing gaps, potential risks and islands of automation on a staged basis minimizes costly disruptions to operations and provides greater flexibility as equipment and data needs evolve over time

Tips and Tricks for Selecting a Process Manufacturing ERP

Over the years, the enterprise resource planning (ERP) solutions have proved to be a crucial tool that can help transform any business by boosting its productivity and operational efficiency, and eventually improving its bottom-line.

Big Opportunities in IoT Tech for Process Manufacturing

The report examines the technology by software, hardware and networking elements, all of which comprise the IoT system. Software is forecast as the fastest growing market (31.0% CAGR) over the next five years; although hardware currently has the largest installed base.

Records 1 to 11 of 11

Featured Product

MRPeasy - ERP for Small Manufacturers That Delivers Results

Always know what you have in stock and what you'll need to fulfill orders. Never forget to order parts on time or fail to notice a late delivery from your vendor. Easily create manufacturing orders and schedule them automatically according to resource availability or delivery deadline. Generate accurate cost and lead time estimates and provide customers with quick quotes. Receive notifications when orders are late or inventory levels reach a critical point. Ensure seamless communication between sales, production, warehousing, procurement, administration, and finance. Integrate with popular accounting, CRM, and e-commerce apps. MRPeasy is an ERP software for small manufacturers that gives you all that and more. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries. Try for free, no credit card needed.

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.

.jpg)

.jpg)