Static bills of materials, disconnected tools, and manual workflows limit scalability. They slow timelines, erode margins, and make it harder to manage increasing product complexity across the lifecycle.

The Next Evolution of Configure-to-Order in Manufacturing

The Next Evolution of Configure-to-Order in Manufacturing

Bruce Bookbinder,Product Marketing Manager | Aras

Configure-to-order (CTO) has long promised mass customization without the high cost and risk of engineer-to-order (ETO) approaches. While CTO offers many clear advantages, traditional models can fall short. Static bills of materials, disconnected tools, and manual workflows limit scalability. They slow timelines, erode margins, and make it harder to manage increasing product complexity across the lifecycle.

Manufacturers face growing pressure – from both consumers and partners – to deliver tailored products with faster lead times, greater efficiency and traceability, and fewer errors. To meet these demands, new technologies and strategies are emerging that enable manufacturers to modernize CTO through digital integration, modular design, improved application capabilities and better-connected data.

The Problem with Traditional CTO Models

Traditional CTO models work well on a small scale – particularly for teams that can easily collaborate across product lifecycle stages. However, as product lines expand and teams grow, predefined configuration rules quickly become too rigid and simplistic to support evolving product iterations and modular design.

Additionally, legacy CTO models often operate in silos, with design, engineering, production, sales, service teams working from different datasets, instructions, and standards. This disconnect leads to product inconsistencies, quality issues, delays, unsold inventory, and increased costs. While configurators have occasionally helped – for example, by bridging gaps in BOM management – they fall short when broader, integrated data and robust product architecture are needed.

The Role of Modular Product Architectures and Unified Data

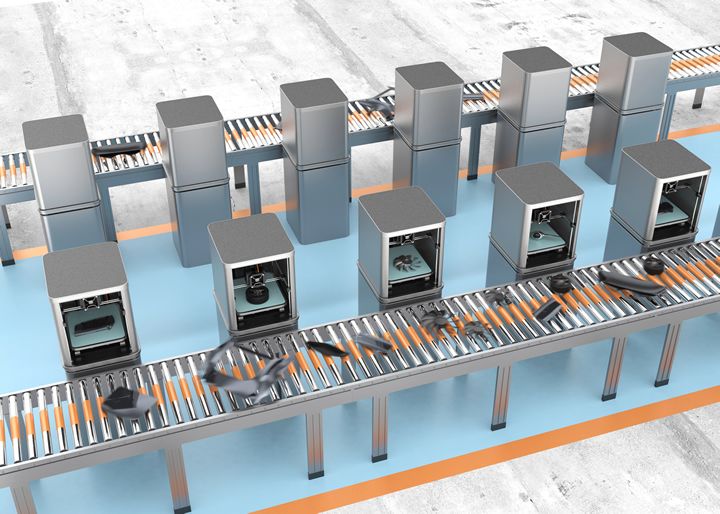

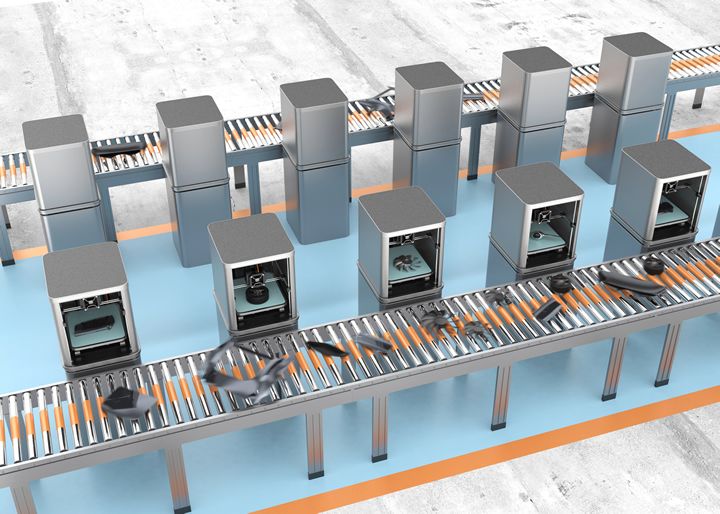

To overcome the limitations of rigid, surface-level configuration rules, manufacturers are adopting advanced technologies that support increased modular product architectures. Modular design enables the creation of standardized components that can be reused across different product modules and variants.

For example, attributes like size, color, performance level, and add-ons can be pre-engineered and tested for compatibility, ensuring reusability across configurations. This simplifies engineering, streamlines supply chain requirements, and enables faster delivery of tailored products. With modularity, configuration rules become more flexible and dynamic, applying across various structures and components. Both parts and rules evolve into reusable, standardized building blocks – scalable across teams and product lines.

This flexibility is made possible by unified information models and shared data access. When all teams – regardless of their role in the product lifecycle – work from a common digital foundation, configuration logic, product structure, and lifecycle data stay aligned. The result is a cohesive, traceable, and efficient CTO process that extends from initial configuration through maintenance and end-of-life.

Improving CTO Outcomes With the Digital Thread

One of the most powerful enablers of next-generation CTO is the digital thread – a connected, contextualized flow of product data and assets spanning all relevant domains of the product lifecycle. With a platform that enables a digital thread, all types of data become configurable, version-controlled, and traceable – making them accessible and actionable across teams.

Digital threads also unlock broader value, particularly as PLM platforms increasingly incorporate artificial intelligence (AI). Together, AI and the digital thread create a “connected intelligence”, enabling the system to validate configurations, perform rapid QA on product components, and identify inconsistencies before they impact production. In cases where a CTO project requires a more customized engineer-to-order (ETO) approach, the digital thread provides the deeper data context needed to support that transition smoothly.

Tips for Enhancing CTO Models and Technologies

Whether you’re already operating with a CTO or hybrid model, or planning to transition into a CTO manufacturing strategy, the following best practices can help your team achieve stronger outcomes:

- Clarify your business requirements: Understand what your organization truly needs and can sustain with CTO. Tailor your modularity strategy and platform investments based on your current goals and resources.

- Choose a scalable, flexible platform: A cloud-based PLM and digital thread platform provides the flexibility and scalability necessary to manage large-scale product variability. massive amounts of data on product variability. Cloud infrastructure also ensures real-time data access across locations and teams.

- Integrate CTO and modularity into your company culture: Successful CTO requires cross-functional buy-in. Create a clear vision, define key steps, and implement a change management strategy that’s supported at every level.

- Start small with modular CTO: Run pilot projects using prototypes, small teams, or controlled test environments. This allows teams to build the skills and confidence needed to scale modular design and production.

- Empower program leaders to make strategic CTO changes: A CTO transition needs strong leadership. Appoint a committed program manager with the authority, resources, and organizational support to drive strategic change.

- Improve data quality and governance: Digital threads rely on clean, accurate data. Invest in proper data collection, cleansing, management, and governance practices to ensure consistent, trustworthy information across the lifecycle.

- Track ROI and adjust accordingly: Track costs and performance to identify where configuration delivers the greatest value—and use those insights to guide future modularization efforts.

Rethinking CTO as a Lever for Profitability and Agility

While CTO has traditionally been viewed as a sales enabler, a modern approach – powered by modular design and digital thread technology – extends its impact deep into engineering and operations. With a unified data source and a strategic view of modularization, organizations can streamline engineering workflows, reduce production costs, and unlock new revenue opportunities through scalable product variation.

For companies that want to upgrade their CTO strategies, one thing is clear: agility pays off. A flexible, scalable platform empowers teams to assess what’s working, adapt quickly, and make more informed product decisions – accelerating innovation and improving business outcomes.

Bruce Bookbinder is a Product Manager at Aras. He is currently driving strategy for the Aras cloud and SaaS deployments as well as other technical aspects of the Aras PLM Platform. Before Aras, Bruce held several IT management and technology positions at General Electric, Avon Products, Reader’s Digest, and Control Data Corporation. Bruce holds an MS and a BS in Computer Science Management.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product