The Importance of Digitization for Medical Device Manufacturers

The medical device manufacturing sector faces many challenges with respect to their daily operations such as: data collection and reporting, downtime tracking, real-time visibility and shop floor engagement.

Optimizing Integration of End-of-Line Packaging Systems for Medical Devices

Maximizing the capabilities of end-of-line packaging systems for handling medical devices depends upon how smoothly the disparate functions are integrated into a singular, optimized packaging line. Robotics and turnkey integration provide the solution.

Case Study: A Task Force Uses Rapid Prototyping to Evaluate an Emergency Medical Device

A team of engineers and medical experts joined forces during the first wave of COVID-19 to rapidly prototype a medical device. Xometry manufactured 9 prototypes in under 3 weeks, providing advice and rapid production for critical decision making.

How to Safely Manufacture and Ship Vaccines

Vaccines can easily become damaged or unusable at almost any step of the manufacturing and shipping process. Pharmaceutical companies wanting to maintain their margins and high standards of quality need to take measures to prevent error and contamination.

Danny Gets His 3D Printed Bionic Hand

For 21 years, Danny Florence has lived with one hand. But when he became a father, he decided to apply for an Open Bionics Hero Arm. With the help of the maxon driven prosthesis he can now build a strong bond with his son.

Additive manufacturing in the medical industry

Additive manufacturing enables not just personalisation but also, importantly, cost reduction and gains in success. There are sure to emerge many more potential applications.

Acquiring Complex Machined Parts in the "No Bid Zone"

Pharmaceutical companies are partnering with machine shops capable of producing ultra-high tolerance parts for enhanced reliability.

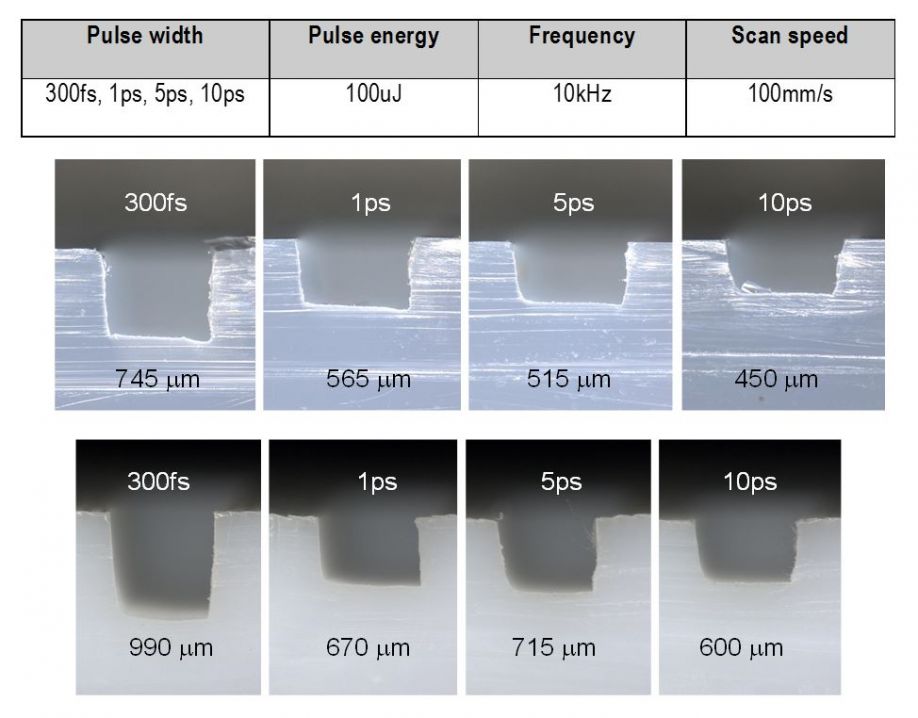

Ultra-Short Pulse Lasers Are Great Tools for Processing Plastics for Medical Devices

As an independent laser integrator with our own application labs in which we test and select the best laser for the job, we have conducted testing on USP lasers for polymer processing and want to share some of our findings and recommendations for success.

Spring Assemblies and Medical Devices: What to Think About Before You Design

When you are working on designs for new medical equipment, thinking about the components you will have to bring together and the systems they will create is essential.

New Tube Cutting Technology Meets Next Generation Production Needs

While legacy stent and tube cutting systems have performed well during recent decades, new cutting technologies coming onto the market offer faster and better cuts, with higher production rates and new and unique cutting capabilities.

Hospital to get first dedicated 3D tissue-printing facility

Steve Dent for enGadget: You still can't get a 3D-printed liver transplant made from your own cells, but an Australian hospital is trying to push the tech into the mainstream. The Queensland University of Technology (QUT) in Brisbane is building a dedicated "biofabrication" space where doctors and researchers can develop tech to model and print cartilage, bone and other human tissue. "It will be the first time a biomanufacturing institute will be co-located with a high-level hospital," said Australian Minister of Health Cameron Dick.

The facility will occupy two floors of the hospital and use state of the art tissue manufacturing tech in surgery procedures. "Our vision for healthcare is that the biofabrication institute will pave the way for 3D printers to sit in operating theaters, ready to print tissue as needed, in our hospitals of the future," Dick said. Cont'd...

Records 1 to 11 of 11

Featured Product

OnLogic Karbon 520 Series of Scalable Rugged Computers

The OnLogic Karbon 520 Series of rugged computers is purpose-built to deliver unwavering performance and reliability in the face of extreme temperatures, vibration, and dynamic power conditions. Powered by the latest Intel® Core™ Ultra processors and validated by MIL-STD-810H testing, the Karbon 520 Series makes it possible to deploy dependable computing for AI at the edge, advanced automation, or critical remote and in-vehicle applications in even the most challenging environments.

Manufacturing and Automation - Featured Company

PI USA (Physik Instrumente)

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1700 people worldwide. PI's customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors and aerospace.