An Island of Manufacturers: What Does "Made in Britain" Mean for the Economy?

A new government could represent a fresh start for British manufacturing, if they increase support for manufacturing businesses and protect the vital jobs they create.

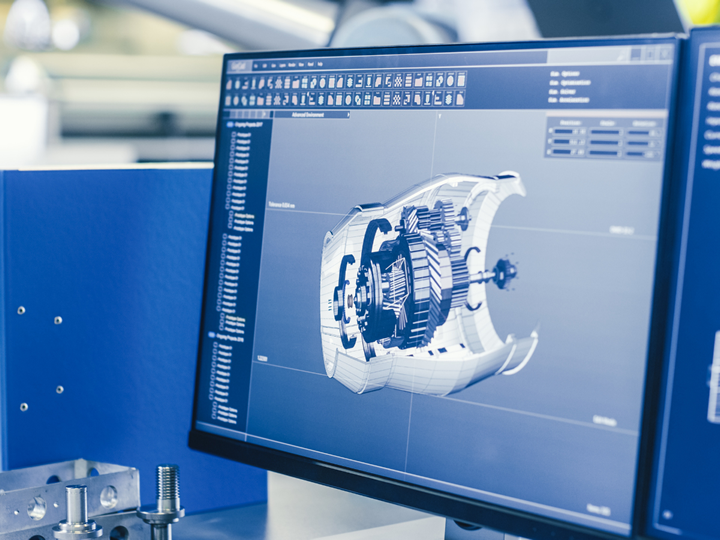

What Is MES & Why Should Manufacturers Invest In It?

Whilst MES has established itself with some of the major manufacturers, there's still a large number of businesses that could stand to benefit from the solution but simply don't have enough understanding about the tangible benefits it can bring to their operation.

Unlocking the Value Potential of Additive Manufacturing

Still seen primarily as a prototyping technology, additive manufacturing is getting a boost from AI and machine learning software that can help with AM decision making.

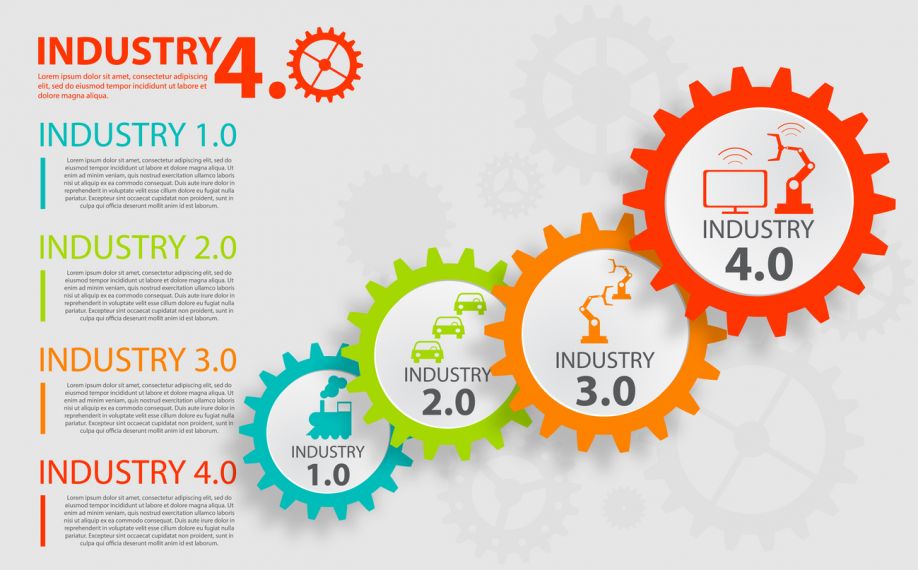

How IoT Will Elevate 8 Types of Equipment in 2023

A rising global population means a higher demand for goods and services. Companies find ways to increase production and quality control, such as through the Internet of Things.

Smart Manufacturing - A Layered Approach to Digital Transformation

One of the main goals of digital transformation is to transform the shop floor into smart manufacturing to help manufacturers to manage their core production operations digitally to maximize the production by minimizing machine downtime and quality losses.

U.S. Manufacturers Falling Behind China in EV Production

Electric vehicles (EVs) are changing the face of auto manufacturing. As concerns over climate change grow, zero-emission cars are becoming an increasingly crucial part of this industry. However, recent reports suggest the U.S. is falling behind in production.

FANUC America Nearly Doubles Michigan Campus to Accommodate Automation Demand

The global automation solutions leader invests in US manufacturing with plans of a second expansion in three years to meet growing need

Four Lessons Manufacturers Learned from the Pandemic

Many investments made by manufacturers over the past two years delivered new capabilities and efficiencies that should be carried forward as manufacturers look to the future in search of new business growth.

Carbon Offsetting for Manufacturing Facilities

Given the advanced state of anthropogenic climate change and widespread awareness of its human impact, it's time for manufacturing to adopt carbon offsetting practices.

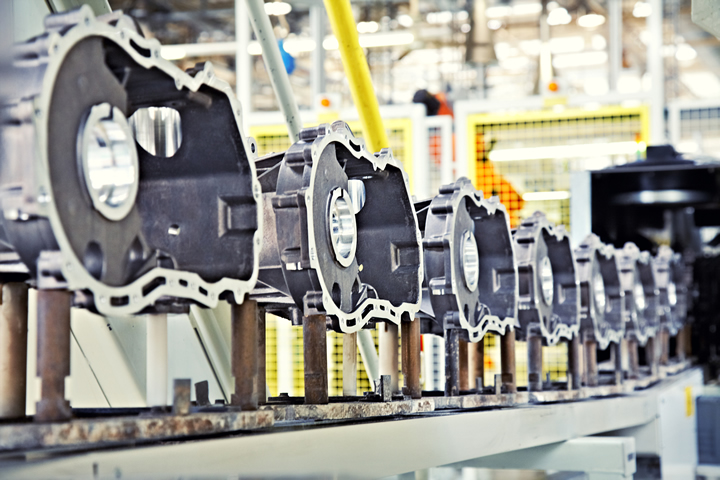

The Benefits Of Factory And Manufacturing Automation For Today's Industry

In this article, we are giving you a complete guide through factory and manufacturing automation. Continue reading to find out more about the nature of both of these groundbreaking processes that have changed the industry approach toward production forever.

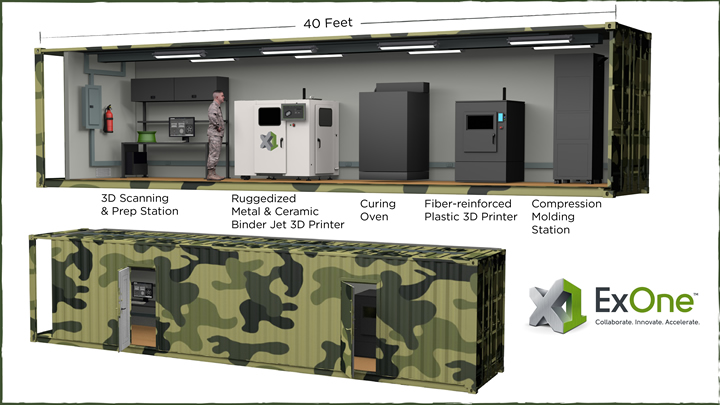

ExOne Developing Portable 3D Printing Factory in Shipping Container for Department of Defense

ExOne has been awarded a U.S. Department of Defense contract to develop a fully operational, self-contained 3D printing "factory" housed in a shipping container. Now under development.

Opportunity Tonasket It's a Lifestyle Choice

Our primary mission is to promote economic development and growth in the city of Tonasket and surrounding area. We wish to assist and promote existing businesses wishing to relocate, local businesses wishing to expand and local individuals wanting to startup a business.

Manufacturing and Processing: Smart Moisture Measurement Technology Continually Optimizes Product and Process Quality

Instant measurement and production line correction is enabled since calculations are performed in real-time inside the sensor and data is analyzed multiple times per second with integrated software

3D Printing Will Soon Be a Game-Changer in the Manufacturing Industry. Here's Why

Until now, manufacturers have been dipping their toes and getting familiar with the technology, using it to create prototypes rather than final products. But that is changing. It's only a matter of time before AM makes the leap from prototyping to manufacturing.

Are You Fit for 3D Printing Success?

Additive Manufacturing is not intended to replace conventional or traditional manufacturing, but rather compliment it. When implemented correctly, AM offers manufacturers real flexibility and design freedom while enabling more resilient and robust value chains.

Records 1 to 15 of 43

Featured Product

KEB VFDs for High Speed Motor Control

KEB's VFDs are the key to unlocking peak performance in your high-speed machinery. Engineered for precision control, even without feedback sensors, our F6 and S6 drives utilize advanced software and high-frequency output. This ensures smooth operation, reduced vibration, and optimal efficiency. Whether you're building turbo blowers, power generation systems, or other high-speed applications, KEB VFDs deliver the reliability and performance you need.

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.

.jpg)

.jpg)

.jpg)

.jpg)