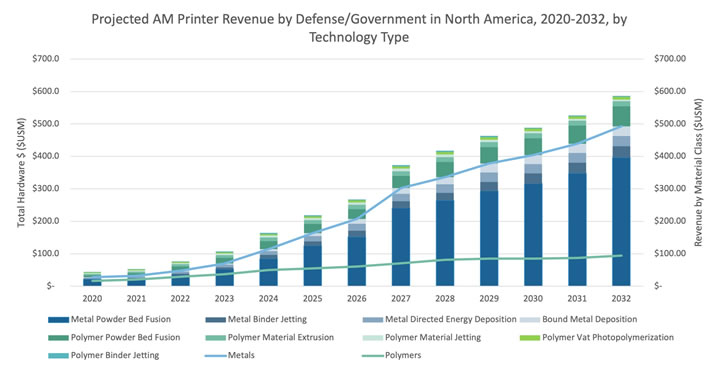

AM Research Publishes In-Depth Market Study on Additive Manufacturing for Military and Defense; Estimates $0.3B in Direct DoD Spend in 2023, Growing to $1.8B in 2032

The comprehensive study sheds light on the rapid evolution and potential impact of additive manufacturing technologies on the defense and military landscape.

How Additive Manufacturing Can Step Up to Print Emergency Replacement Parts in the U.S. Military

Technological innovation in the U.S. military is revolutionizing defense, responding to natural disasters, and so much more, but it also creates unique challenges. 3D scanning combined with additive manufacturing (AM) can step in to print emergency replacement parts.

Evolution of the Need for Expeditionary Manufacturing

There is a demand signal to produce a machine capable of Metal printing on the front lines. Phillips has developed a Hybrid technology that adds a Wire fed Direct Energy Deposition head to a Haas machine.

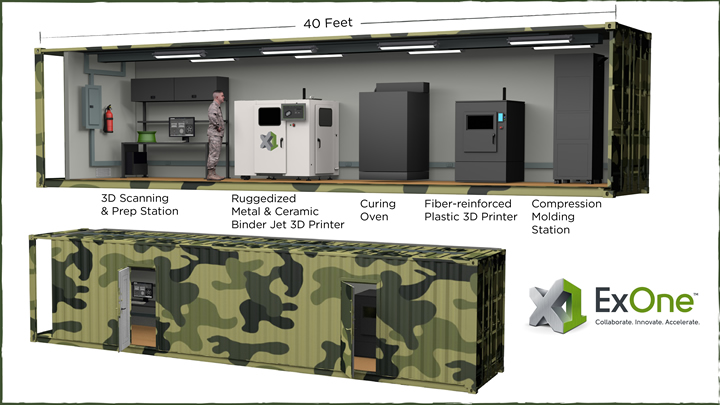

ExOne Developing Portable 3D Printing Factory in Shipping Container for Department of Defense

ExOne has been awarded a U.S. Department of Defense contract to develop a fully operational, self-contained 3D printing "factory" housed in a shipping container. Now under development.

U.S. Army Research Lab Selects 3D Systems to Develop World's Largest, Fastest Metal Powder 3D Printer

United States government invests $15 million towards the development of the next generation of metal 3D printing technology - advancing U.S. competitiveness and national security.

How to Keep Your Manufacturing Site Secure in the Age of the IIoT

Manufacturing sites of all kinds now find themselves potentially vulnerable to new types of cyber-attacks - the kinds that turn our own connected devices and equipment against us.

GE Awarded $9 Million from Office of Naval Research to develop framework enabling the rapid qualification and certification of 3D Printed Parts

3D printing could replace legacy manufacturing processes no longer in use to produce decades-old replacement parts

The US Navy 3D printed a concept submersible in four weeks

Andrew Liptak for The Verge: The team began work in August 2016, and used a massive industrial 3D Pinter called Big Area Additive Manufacturing (BAAM) to manufacture six carbon fiber sections, which were then assembled into the 30 foot long vehicle.

Researchers fire 3-D printed ammo out of a 3-D printed grenade launcher

Mr. Seung kook “Sunny” Burns and Mr. James Zunino for US Army Blog: Researchers at the U.S. Army Armament Research, Development and Engineering Center (ARDEC) successfully fired the first grenade created with a 3-D printer from a grenade launcher that was produced the same way. This demonstration shows that additive manufacturing (commonly known as 3-D printing) has a potential future in weapon prototype development, which could allow engineers to provide munitions to Soldiers more quickly.

The printed grenade launcher, named RAMBO (Rapid Additively Manufactured Ballistics Ordnance), was the culmination of six months of collaborative effort by the U.S. Army Research, Development and Engineering Command (RDECOM), the U.S. Army Manufacturing Technology (ManTech) Program and America Makes, the national accelerator for additive manufacturing and 3-D printing.

RAMBO is a tangible testament to the utility and maturation of additive manufacturing. Cont'd...

Records 1 to 9 of 9

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.