WHY 3D PRINTING - BENCHMARKING AGAINST TRADITIONAL MANUFACTURING

Manual Work Meets Modern Automation to Empower Workers With Handicaps

Lessons from World War II on Manufacturing and the COVID-19 Pandemic

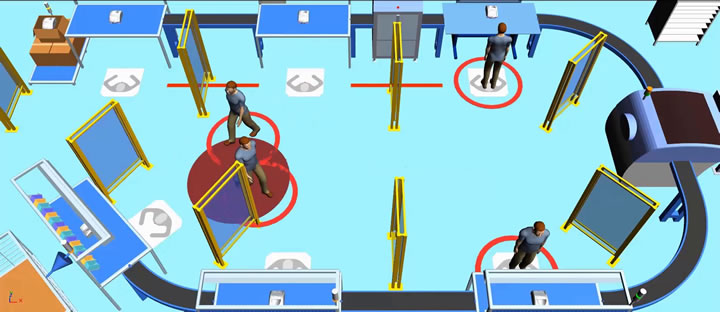

Siemens introduces workplace distancing solution to manage "next normal" manufacturing

How Manufacturing Can Rise from the Ashes of the Old Norms, Stronger and Better

Quality 4.0 Takes More Than Technology

ManufacturingTomorrow - Special Tradeshow Coverage

ATX West, MD&M and Design & Manufacturing

Augmented Reality in Manufacturing

Sierra College Hosts US Dept. of Defense Project MFG™ Challenge

Switching to Biobased Plastics: IDTechEx Research Asks Why So Slow?

Washtenaw Community College to showcase advanced manufacturing, cybersecurity programs at NAIAS

FROM FANTASY TO REALITY: FORD'S NEW $45 MILLION ADVANCED MANUFACTURING CENTER BRINGING THE FUTURE TO LIFE - TODAY

Automating Back-End Processes in Advanced Manufacturing

SFA Explores MFG Day - Three journeys to close the MFG skills gap explored

Russell Compact Sieve® skyrockets efficiency at New Balance additive manufacturing center

Records 16 to 30 of 43

First | Previous | Next | Last

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Manufacturing and Automation - Featured Company