Automation Alley announces new year-long format for Integr8 event

New approach will offer up to a dozen Integr8 roundtables series events exploring Industry 4.0 topics and an Integr8 Roundtable Summit on Oct. 3

Abingdon School UK Teaches 21st Century Skills With Makerbot 3D Printers

As schools look to bridge the skills gap in the workforce, 21st century skills like 3D design, design thinking, and CAD will be more critical now than ever before.

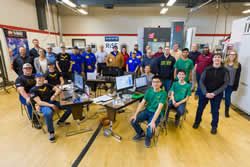

Integrated Engineering Program Opens Up Opportunities for Students

"The PLTW Engineering Program at Corona High School in Corona, California, is designed to

set the students up to give them the best real world breadth education to be able to go directly

into the manufacturing field..."

The Top 4 Applications of 3D Printing Technology from Education, Medicine, Industry to Art

The impending uses of 3D printing are still being exposed. This article highlights some of the applications presently under way that are probable to be in general use first.

Sierra College Hosts US Dept. of Defense Project MFG™ Challenge

Kennedy High School team wins Project MFG™: Next Generation Manufacturing™ Challenge held in Sierra College Advanced Manufacturing lab.

Swinburne to establish world first Industry 4.0 Testlab

Swinburne has received a record $135 million grant from engineering giant Siemens to digitise its Factory of the Future and create Australias first fully immersed Industry 4.0 facility.

SME Launches High School Membership Program to Build the Manufacturing Workforce Pipeline

With an anticipated skills gap of 2 million jobs by 2025, the manufacturing industry needs to attract and inspire the next-generation workforce,

Basic Assembly Skills Are as Important as Ever, Even in This Technology-heavy Era

Whatever advancements the future holds, production facilities will continue to need individuals who have a wide range of basic assembly skills and those individuals will always be indispensable.

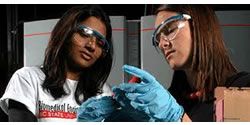

Robots Helping Grads Get Jobs

Not many students can claim they have hands-on experience with automation and robotics going into an interview. Looking at the question with a macro lens, our students are offered job opportunities on being well-rounded, even at the sophomore-level when many accept summer/semester-long internships.

Developing Manufacturing Workers Who Are Job-Ready on Day One

Over the next decade, 3.4 million manufacturing jobs will likely be needed, and 60% of them are likely to be unfilled due to the talent shortage. How can we close that number (and the skills gap)?

ULTIMAKER PARTNERS WITH THE UNIVERSITY OF ILLINOIS TO DEVELOP A NEW ONLINE COURSE ON 3D PRINTING

Ultimaker, a leading 3D printer manufacturer, has partnered with the University of Illinois, and Coursera, an education platform that offers online courses from top universities and organizations worldwide, to create a series of 3D printing courses that will be open to learners around the world.

Records 1 to 11 of 11

Featured Product

Super Air Knife Replaces Blowers & Saves Energy

Super Air Knife reduces compressed air usage & noise when compared to other blowoffs. The Super Air Knife offers a more efficient way to clean, dry or cool parts, webs or conveyors. It delivers a uniform sheet of laminar airflow across entire length.

https://exair.co/184_523

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.