The Real ROI of AR in Manufacturing: Beyond the Hype

If you think AR's real value is still theoretical, think again. Over the last decade, forward-thinking manufacturers have adopted AR solutions with measurable gains that go beyond aesthetics.

Industrial Metaverse: Pioneering Remote Maintenance Solutions

The Industrial Metaverse is emerging as a transformative technology in manufacturing and maintenance, blending advanced technologies to create a more efficient and responsive operational landscape.

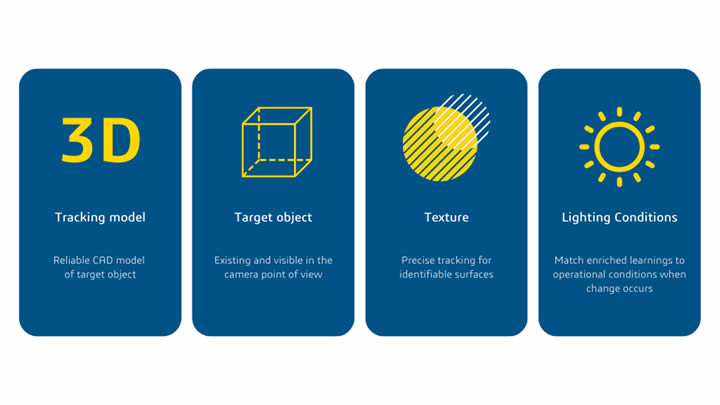

Do You Know the Role of Tracking in Augmented Reality?

Tracking is used in the DELMIA Augmented Experience solution to identify the equipment to be assembled or inspected. Thanks to its 3D model, it simultaneously locates several elements at once, and displays the digital information required for the industrial process.

How Automation-as-a-Service Combined with AI & AR/VR Is Benefitting Manufacturers

By integrating AR/VR (augmented reality and virtual reality), robotics, machine learning, and AI (artificial intelligence), AaaS solutions automate repetitive tasks, optimize processes, and facilitate data-driven decision-making.

3 ways Augmented reality advances assembly operations

Wendy Mlynarek, DELMIA Strategic Business Development and Marketing Director takes a closer look at how augmented reality is playing a vital role in assembly operations.

Improving Manufacturing Operations with Augmented Reality Solutions

When workers are located in different regions or countries, it can be difficult to provide on-site support and training. Vuzix AR glasses can provide real-time guidance from remote experts, enabling workers to perform complex tasks without the need for on-site support.

How VR and AR are Creating the Next Generation of Welders

By replicating authentic job scenarios in a safe and virtual setting, it's possible to both test and train welders effectively while simultaneously minimizing your long-term cost base.

AR & VR in Manufacturing - Q&A with Will Gee, CEO of Balti Virtual

Balti Virtual recently piloted an immersive training experience for The Army, which replaced a slide deck and video. The result was a gamified training experience that created more engagement and better retention than traditional methods.

Pick-by-Vision Has Arrived

There is very little new to witness at MODEX 2020 regarding pick-to-light or voice-picking. The same vendors in these product categories have been selling the same products for a decade or more. The good news is that pick-by-vision has arrived.

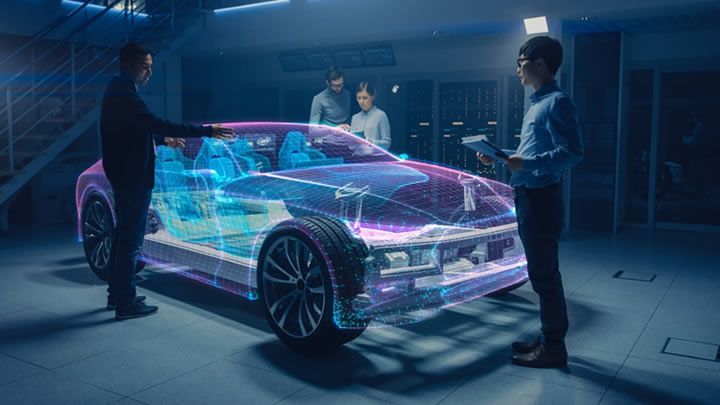

Augmented Reality in Manufacturing

Some people confuse AR with virtual reality. Virtual reality (VR) is a complete immersive experience that shuts out the real world. Augmented reality superimposes a computer generated (CGI) video onto a camera captured video.

Virtual and Augmented Reality in Manufacturing

Recently, the manufacturing sector has discovered the potential of AR and VR in cutting costs and increasing safety and productivity. But what exactly are the applications of this revolutionary technologies in the factory?

ARC White Paper: AR in Manufacturing

Learn how manufacturers are using augmented reality to onboard new workers faster and to help workers of all skill levels become more effective.

Game On: Augmented Reality Is Helping Factory Workers Become More Productive

AR is one of many tools GE is applying to fulfill its vision of the digital "Brilliant Factory." Last week the company announced plans to train workers for the arrival of 3D printing, big data, robotics, digital and lean manufacturing, and other advanced technologies on the factory floor.

Virtual Reality in Manufacturing

In manufacturing, a MR system can indicate the name and attribution of parts by displaying virtual labels overlaying the objects. The system can guide an assembler, showing virtual arrows as to where the part goes into an assembly.

How Practical AR Tech Tools Can Transform Manufacturing Processes

The most effective applications of AR technology are designed to error-proof and streamline manual assembly and manufacturing processes, utilizing a combination of industrial strength projection technology and sophisticated software to present an intuitive and interactive visual guide.

Records 1 to 15 of 15

Featured Product

PI USA - High-Speed Hexapod for Nanopositioning

To meet industrial demands for higher dynamics, reliability and precision in 6DoF positioning systems, PI engineers came up with a new hexapod concept, based on direct-drive lever actuators. This new concept reduces complexity, improves performance, and minimizes wear.

Manufacturing and Automation - Featured Company

NORD DRIVESYSTEMS

With four production facilities in the Midwest, on both coasts, and in the South, NORD is prepared to serve you with some of the shortest lead times in the industry. We house extensive component inventory, allowing us to assemble and ship 25% of all standard product orders same or next day!

.jpg)