Do You Know the Role of Tracking in Augmented Reality?

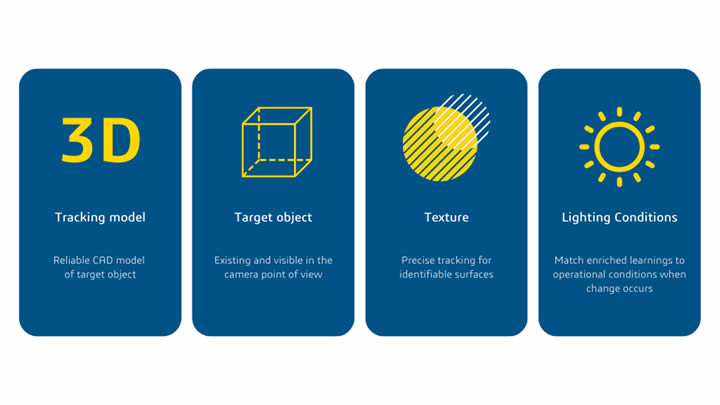

Tracking is used in the DELMIA Augmented Experience solution to identify the equipment to be assembled or inspected. Thanks to its 3D model, it simultaneously locates several elements at once, and displays the digital information required for the industrial process.

Efficient Warehouse Management: Saving Costs with Rapid Pallet Trackers and Basler ace Cameras

Artemis Vision, a company with more than 10 years of experience in quality assurance for manufacturing processes, develops vision systems for industrial automated inspection and logistics optimization that deliver reproducible and reliable results.

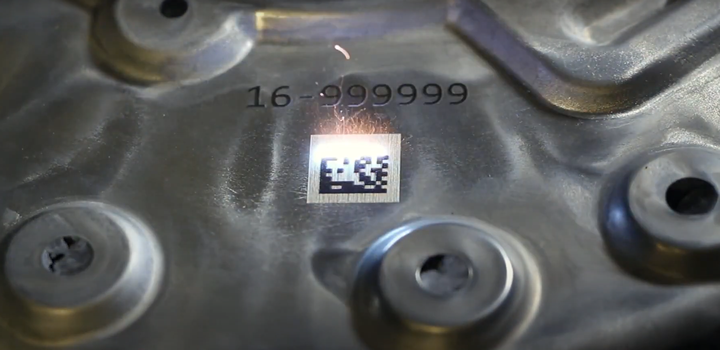

Why Laser Technology Is a Good Automation Tool for Traceability

Automating the traceability process is essential for manufacturers who want to avoid production bottlenecks, reduce production costs, and improve the marking quality to meet OEM traceability requirements.

Digital Twin and Digital Thread: The Innovative Way to Track Product Life Cycles

The interesting thing about modern products is that smart technology can enhance them. That makes them traceable throughout their life cycle, and technologies such as cloud platforms enable the products to be tracked during their life journey.

Records 1 to 4 of 4

Featured Product

Quality assurance in the manufacturing industry

Efficiency and precision with CSP software. In the highly competitive world of manufacturing, quality assurance is a critical factor for success. CSP offers you state-of-the-art software solutions specifically designed to ensure the highest standards of quality assurance in the manufacturing industry.

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.