AM Produced Mandrels Provide New Opportunities for Composite Manufacturers

Connecting Robot Accessories to Any Industrial Network

How the Additive Manufacturing Industry Emphasized End-Use Part Production at Rapid + TCT 2023

Being a Good Steward

Benefits of Gearbox Customisation for OEMs

Metal Additive Manufactured Parts for Racing Car

Total Cost of Ownership - Unwrapping the Hidden Costs of Manufacturing

The Case for Mass Finishing for AM Parts and Components

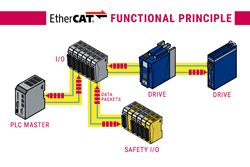

5 Advantages of Using EtherCAT for Motion Control

Case Study: Plug & Produce in Sensor Production

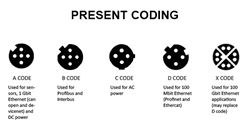

M12 Connections Explained: What Are They & Which Are Best For Your Purpose?

6 Reasons to Choose EDM Over Traditional Machining for Better Results

Cincoze CV-117/P1001 Enhanced Productivity for Stone Processing Machine

3D Printing New Parts for a Classic Ferrari

It's Not Just Consumers Who Prefer To Buy Online

Records 16 to 30 of 84

First | Previous | Next | Last

Featured Product

Quality assurance in the manufacturing industry

Manufacturing and Automation - Featured Company

.jpg)

.png)

.jpg)