Choosing a Robotic Spindle for Deburring

The nature of the deburring task is highly repetitive, dirty, and carries a risk of injury. Retaining personnel for such a strenuous and messy job is challenging. Robotic deburring is an appealing option for these reasons, plus the results are more precise and repeatable.

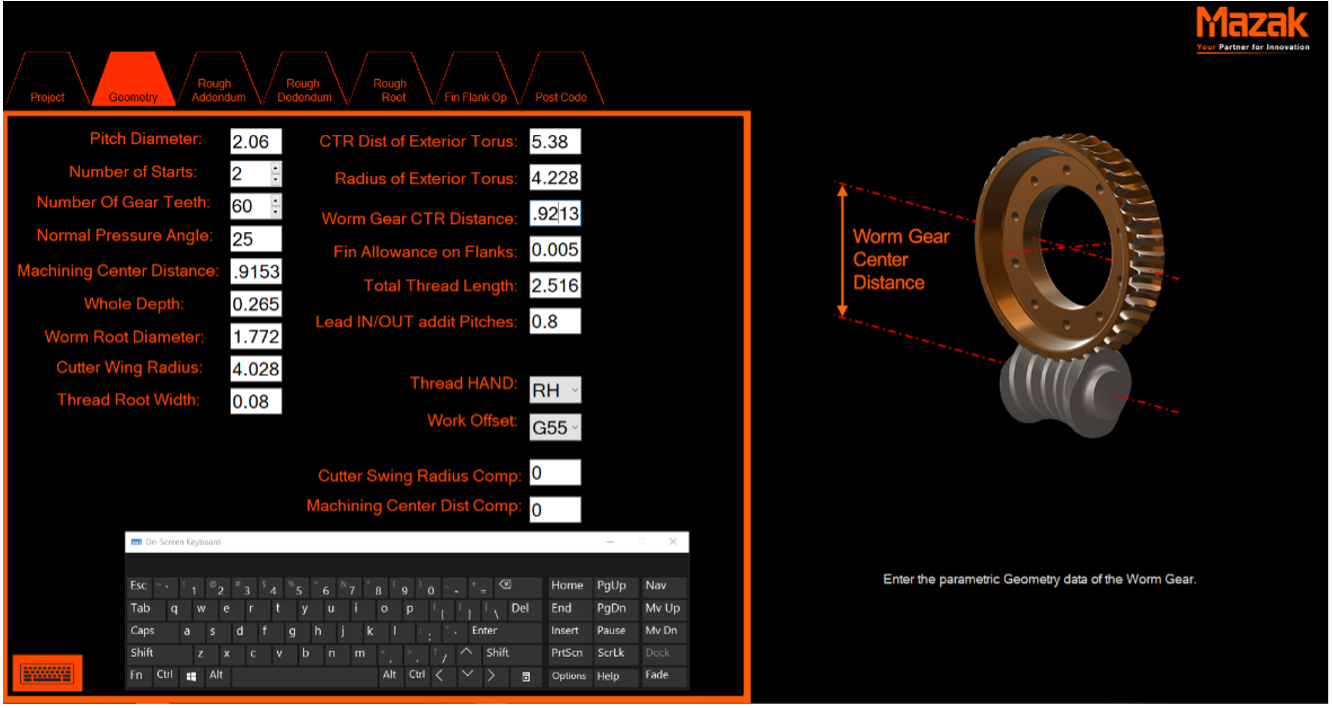

Customer Challenge: Double Enveloping Worm Threading on a Multi-Tasking Machine

While it's common for many shops these days to cut gears on Multi-Tasking machines such as our INTEGREX i-450ST, fulfilling the customer's request for tailored software to aid in programming proved a bit challenging to overcome.

Liquid HollowStream Cone Nozzles and Electrostatic Filters

The contractor used a cleaning solution to break down the contamination prior to rinsing and drying. They had to be careful with the electrostatic filters as the ionizing wires that are used to charge the particles are very thin and prone to breaking.

HEIDENHAIN In Action at OMIC

Exciting manufacturing research is happening daily at OMIC R&D (Oregon Manufacturing Innovation Center - Research & Development) and many types of HEIDENHAIN precision measurement components are working inside.

Transforming Legacy Manufacturing Enterprises With AI on the Edge

This article discusses how legacy manufacturing enterprises can harness the latest technologies, to optimize factory operations without having to ramp up infrastructure investment.

The Advantages of Digital Pressure Sensors in Industrial Applications

Learn when and why it is best to use digital pressure sensors in industrial applications and what types of features can help increase system safety, efficiency and reliability.

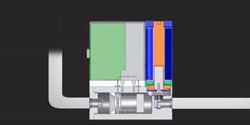

In the Vacuum Workshop

In the semiconductor industry, cleanliness and precision are absolutely critical. Swiss vacuum specialist VAT therefore partnered up with maxon to develop a drive system for wafer processing.

Engineered-to-Order Mission Critical Hydraulic Manifolds Drive Overall Equipment Effectiveness of Fluid Power Systems

With increased energy efficiency shorter flow paths minimize pressure drops reducing installation costs. Equally important in the ETO design process is the reduction of fluid leaks and upkeep.

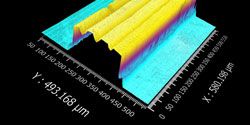

Advanced Metrology Tools Enable Reliable Engine Light-Weighting

This article analyzes the role of cutting-edge optical metrology tools have in facilitating the manufacture of light-weighted engine components. Light-weighting is a priority for automotive OEMs in their quest to adhere to exacting engine efficiency and emission guidelines.

4 Factors Impacting Accuracy and Repeatability of Your Scales

Even the highest quality industrial weighing scales are affected by several factors such as their surrounding environment, load cell accuracy, interferences etc. To prevent the negative impact of these factors, it's important to understand them.

Major Components of Mass Flow Meters and Controllers

A mass flow meter (MFM) has five major components: flow body, flow conditioning section, flow sensor tube, bypass, and electronics. A mass flow controller (MFC) has the same components as an MFM, but also has an integral control valve mounted on the same flow body as the MFM

Track and Protect Vital Industrial Assets with Print Yourself Asset Tags

Tagging essential equipment and tools guards against theft, loss, and misplacement while improving workflow, maintenance, and asset management.

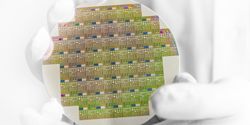

Plasma Wafer Processing Tools

During manufacturing of integrated circuits (ICs), it is necessary to perform many deposition and etching steps to build the necessary internal structures. Among the most common are ashing, or stripping, to remove photoresist from etched wafers..

How the Right Rollers Ensure a Better End Product

Tighter tolerances translate into less vibration, fewer jams, and increased performance consistency all important aspects of any manufacturing process.

When Should You Re-Manufacture or Refurbish Equipment?

In most cases, re-manufactured hardware is better because its closer to new. That doesnt mean refurbished hardware is bad, just that you should remain aware of the differences.

Records 1 to 15 of 15

Featured Product

Rapid Prototyping with the Modular Motor Series

Quick to configure. Quick to build. Quick to deliver. Parvalux understands the importance of getting product in the hands of customers quickly and efficiently. The Modular Range does just that allowing customers to configure their own solution, selecting motor and gearbox, adding encoders and brakes to create a solution perfectly suited for their specific applications such as conveyor belt systems, picking systems, parcel sorting equipment, pallet shuttles and automated storage and retrieval systems (ASRS). Read our modular range guide for specifics.

Manufacturing and Automation - Featured Company

Fronius Perfect Welding

We aspire to produce more than just welding systems, which is why we are the innovation leader for arc welding and are constantly developing welding processes further. In addition to welding technology for robot applications, we offer solutions for manual gas shielded arc welding, for MIG/MAG, TIG, and MMA welding processes. We also implement automated, complete welding solutions tailored to customer requirements in the field of welding automation. After all, welding creates connections - between metals, between industries, and between people. Connected by the arc, by passion, by the beat of welding.