Tagging essential equipment and tools guards against theft, loss, and misplacement while improving workflow, maintenance, and asset management.

Track and Protect Vital Industrial Assets with Print Yourself Asset Tags

Track and Protect Vital Industrial Assets with Print Yourself Asset Tags

Del Williams | Technical Writer

For almost any sized company or institution with assets that need to be tracked –including industries such as automotive, manufacturing, technology, construction, healthcare, and government – it is essential to efficiently tag, track, and protect required assets. This commonly involves smartphones, laptops, machinery, construction tools, or diagnostic instruments.

Without proper asset management, equipment and tools shared across departments or jobsites can be misplaced, lost, stolen, or inadequately maintained. Asset and financial audits can get complicated. So, asset tags are utilized to ensure efficient workflow, reduce administrative overhead, and keep tools and equipment in good working order.

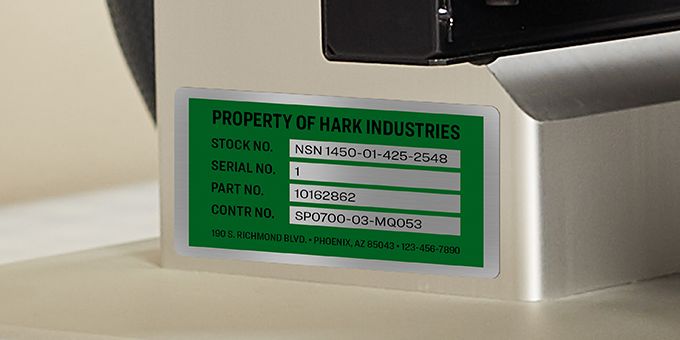

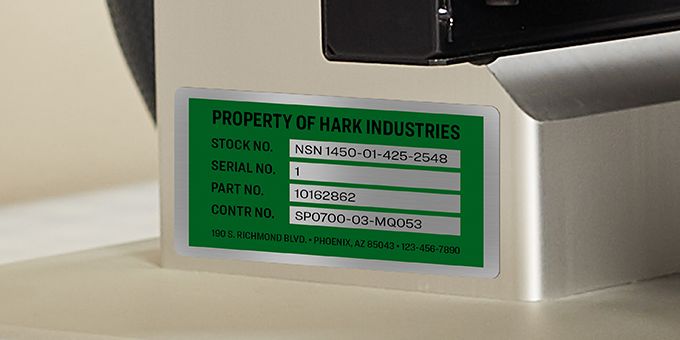

Asset or property tags, also known as equipment tags or labels, usually take the form of barcode labels attached to equipment, tools, and machinery. When scanned, this enables easy identification and processing. This capability is crucial when the tools or equipment are shared across jobsites or departments, checked in/out, or are otherwise prone to pilferage or misplacement.

In such conditions, the use of asset tags with barcodes that can be quickly scanned to provide needed information helps to improve security and workflow, maintenance and lifecycle management, as well as accurate inventory record keeping and financial depreciation to meet audit requirements.

However, successfully achieving this requires utilizing a combination of the right asset tag labels, asset management software, and barcode scanners for the job. One sticking point in this process has been the conspicuous absence of high-performance print yourself asset tags.

While traditional print yourself labels can be inexpensive, these often have not been durable or sticky enough, and typically offer poor print quality.

On the other hand, custom printed labels are usually high quality, but are expensive and require long lead times with high minimum order quantities. With custom printers, a typical investment of $400 or more is needed just to get started. Not all companies need 500 asset tags at a time. It can be a big commitment to decide up front what text and numbers to include on each custom label.

Due to industry innovation, however, low cost, high-performance industrial asset tags have been developed to improve security and workflow. Because these durable asset tags can be customized and printed as needed with an existing laser printer in minutes, this enables easier, more economical tracking of necessary equipment and tools for operations and asset managers.

This approach not only works with traditional one-dimensional (1D or linear) barcodes, but also for two-dimensional (2D) barcodes, which hold far more data in less space by using two dimensions to more efficiently encode data.

While 1D barcodes can typically encode data such as location, department and IP address (an identifying number for network hardware), 2D barcodes can contain not only website addresses but also images and voice.

Such labels, however, can only successfully serve as industrial asset tags when they reliably affix to tools, devices or instruments, remain undamaged, and scan properly. Failing this can lead to delayed device checkouts, lost gear, and high equipment replacement cost, as well as inaccurate inventory counts and botched audits.

Choosing the Right Label

Selecting the best label for the job depends on a number of factors, according to Tina Huff, Group Product Manager at Avery Products Corporation, a provider of industrial and commercial label products.

“Start by factoring in the work environment,” says Huff. “Think about where the asset will be used, whether it will be indoors, outdoors, affected by rugged use, abrasion, or exposed to water or chemicals.”

For light duty applications, Huff recommends that the asset tags should still be tear resistant and water resistant. This helps to avoid inadvertent label damage and ensure reliable scanner readings.

To withstand more challenging industrial environments, heavy duty metallic labels are typically preferred. While metallic print yourself options are not new, even some of these have had problems in terms of reliability, durability, and ease of use.

As an example, lesser quality pre-die cut labels can come apart inside a printer when the outside matrix material peels off the backing. This can cause serious jams, which render the labels unusable, and can even damage the printer.

Other print yourself labels lack sufficient abrasion or chemical resistance, leading to damaged print and barcode reading errors.

Some metallic label sheets even build up a static charge when printing that can shock anyone who picks the labels up from the printer!

As a solution, however, some metallic asset tags are designed for enhanced reliability, durability, and ease of use.

The heavy-duty Metallic Asset Tags in the new Avery PermaTrack™ line of asset tag labels, for example, are designed to be waterproof, resistant to tears, abrasion, and chemicals as well as shock free.

Because of this, in testing, the labels have provided good barcode scan ability even after 20 cycles of Taber Abrasion with 500 grams of force. Similarly, in further testing, the labels showed essentially no print loss after a 32 second soak in chemicals like Isopropyl Alcohol, followed by 10 abrasive rubs. The labels are also designed to dissipate static buildup, so that no one will get an unpleasant shock.

Once the asset tag labels have been chosen, appropriate label design software is needed. For the best print on demand results, the label printing software should be able to be easily customized to meet changing corporate, departmental, or regulatory demands as conditions or formats change.

However, the problem is that custom printed asset tags have traditionally required a large upfront investment of hundreds of dollars, with relatively large minimum order quantities and no flexibility once they have been printed. As such, the average price is usually over $1 per label.

In response, industry innovators such as Avery have developed a simplified, flexible approach using standard laser printers at a cost as low as $0.15 per label, which avoids high minimum orders. The company’s free online Design and Print Software enables customizable printing utilizing templates.

Employees can create and print their own asset tag barcode labels from pre-designed templates or create them step-by-step on demand at their desk. Most employees find the process intuitive, since it resembles creating an office document from pre-designed templates.

With all the coordination in tracking, inventorying, and maintaining equipment and tools required in an industrial setting, the ability to conveniently print asset tag labels as needed in minutes will go a long way toward keeping facilities and jobsites running efficiently with much less hassle and cost.

For more information visit www.Avery.com/assettags.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product