Unlocking Customer Experience: The Critical Role of Your Supply Chain

Cost implications play a pivotal role in delivering exceptional experiences for end-users. By optimizing expenses, businesses can allocate resources to enhance product quality and service delivery, ensuring customer satisfaction.

BOOSTING PANERA BREAD'S EFFICIENCY WITH CIMON'S PLC AND HMI SOLUTIONS

The initiative aimed not only to streamline operations but also to fit seamlessly within the limited space of retail restaurants, a challenge in the bustling food service industry.

A data-driven approach to supply chain management

On my journey within the manufacturing sector, I've learned that the challenges and trends remain constant, but the approaches to addressing them are continuously evolving. This dynamic presents new opportunities, particularly in fiercely competitive markets.

Don't let delayed ROI delay your investment in smart connected products

Smart connected products can unlock new ways to generate revenue and cost efficiencies. While the payoff may be years away, companies need to invest today to remain not just competitive, but relevant.

A Packaging Look-Ahead for 2024 and Beyond

As packaging converters and their brand/retailer clients look to the future, there are four key areas of focus that are getting a lot of attention: Artificial Intelligence, Sustainability, Automation, and Hiring and Retaining talent.

MODEX 2024 - Special News Feature

MODEX 2024 is happening and our special newspage is loaded with news and product announcements from the event.

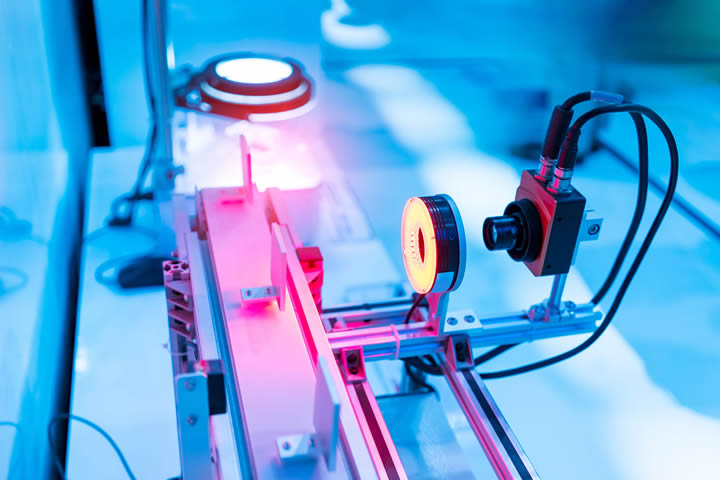

The secret lives of manufacturing defects - How defects pass through the system undetected

Here Zohar Kantor, chief revenue officer at quality inspection pioneer QualiSense, traces how defects enter the manufacturing process and avoid detection.

Specialty Food Manufacturer Meets FDA Requirements and Sustains Growth with MRP Software

Specialty food manufacturer Tait Farm Foods implemented MRP software to get a clear overview of their operation and increase profitability.

Daifuku-Wynright: Manufacturing Visibility & Control with Quickbase

In maintaining equipment required for manufacturing processes, organizations want seamless processes and confidence in their providers. With Quickbase, Daifuku-Wynright has been able to create that peace of mind, and know that they can handle rapidly shifting challenges.

Technology Plays a Key Role in Manufacturing Sector's Recent Resurgence

The U.S. manufacturing industry is undergoing a significant renaissance, indicating a shift toward a more advanced and sustainable domestic ecosystem. There is a renewed energy behind "Made in the U.S.A."

The 5 Warning Signs of Inventory Inefficiency

If you want to know when inventory issues are getting in the way of growth, you need to learn where to look for it. Fortunately, there are some telltale signs to watch for that will let you know you're experiencing inventory inefficiencies

How a Candle Maker Grew from the Kitchen Table to 7 Figures

With 70% of their business taking place during the holiday season, Fontana Candle Company relies on MRPeasy to ensure the timely production and delivery of their products. "I could never do it without MRPeasy," says Eric Roering, Founder and COO.

A Culture of Proactive Compliance

After establishing a compliance team, the reality of just how big a task this was set in. "As we started tackling it, first you get a couple of questions, then you get 20 questions, and then you realize this could be a full-time job, more than a full-time job.

DOOMSDAY CLOCK REMAINS AT 90 SECONDS TO MIDNIGHT

"Make No Mistake": Clock Freeze No Indicator of Stability; Bulletin of the Atomic Scientists Cites Wars, Multi-Dimensional Nuclear Threats, Failures to Address the Climate Crisis, Bio-Threats, and Artificial Intelligence.

Powering Ahead: the Rise of Energy Storage Systems

The ESS market is rife with possibility and growth. As we look ahead to an all-renewable future, we will need to embrace long-duration energy storage solutions and store energy for days and weeks, not hours.

Records 1 to 15 of 824

Supply Chain - Featured Product

Parvalux by maxon - AC or DC electric motors for conveyor systems?

The material handling industry uses conveyors to ensure that products are distributed effectively, AC or DC motors are chosen depending on the weight it needs to carry and the speed at which it needs to work. Learn which type of conveyor motor might be best for your application and how Parvalux can help you select a geared motor from stock or create a fully custom design.

.jpg)