The Role of Conveyor Systems in Warehouse Logistics

The Interplay Between Robotics and Artificial Intelligence in Manufacturing

Inventory Shrinkage - Causes, Consequences, and Tips

What Are The ISO Standards For Barcode Verification?

Manufacturing and Supply Chain M&A Outlook

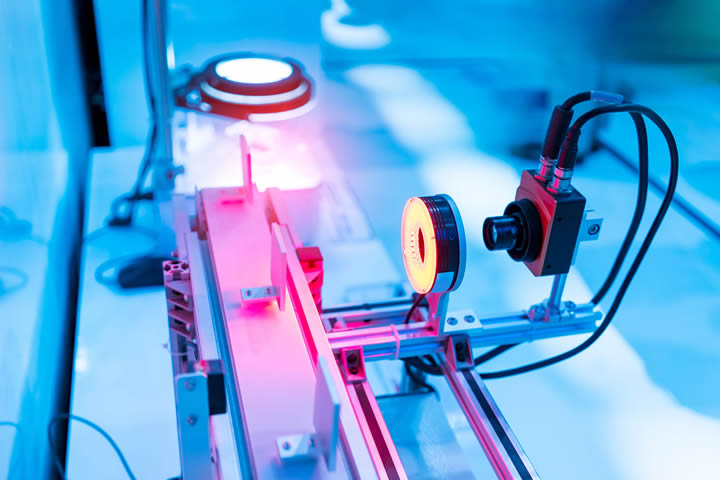

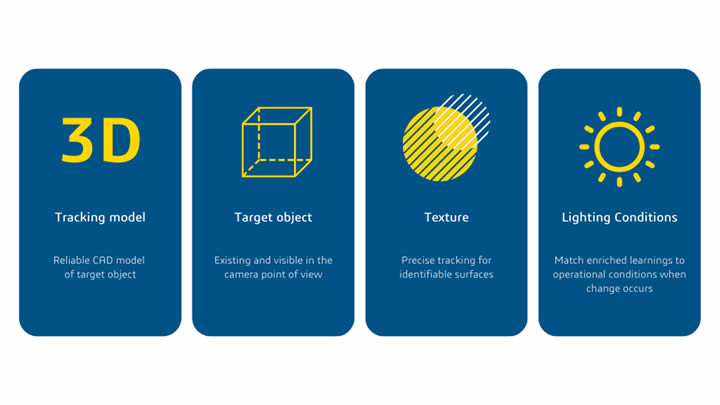

Do You Know the Role of Tracking in Augmented Reality?

Unlocking Customer Experience: The Critical Role of Your Supply Chain

BOOSTING PANERA BREAD'S EFFICIENCY WITH CIMON'S PLC AND HMI SOLUTIONS

A data-driven approach to supply chain management

Don't let delayed ROI delay your investment in smart connected products

A Packaging Look-Ahead for 2024 and Beyond

MODEX 2024 - Special News Feature

The secret lives of manufacturing defects - How defects pass through the system undetected

Specialty Food Manufacturer Meets FDA Requirements and Sustains Growth with MRP Software

Daifuku-Wynright: Manufacturing Visibility & Control with Quickbase

Records 16 to 30 of 845

First | Previous | Next | Last

Supply Chain - Featured Product

.jpg)

.jpg)