Smart Technology Developer Optimizes Processes With RFID-enabled Workforce Tracking

Midwestern Bread Company Transforms Operations with Connected Workforce Solution

How to Navigate Cross-Border Logistics: Finding the Right Partner is a Key First Step

Geek+ drives automation of advanced BMW-producing plant in China

Building Sustainability Into Your Next System Design

Selecting the Right Adhesive-backed Mounts for the Best Use

Optimizing the Manufacturing Supply Chain With 7 Tech-Forward Solutions

How 3D Printing Can Dramatically Reduce Carbon Emissions in the Manufacturing Industry

Updating Warehouse Automation Solutions to Improve Productivity and Profitability

Semiconductor Chiplet: New Design Offers Auto Manufacturers Big Benefits

Robotics Providers: Challenges and Opportunities in a Dynamic Industrial Equipment Market

Looking to the Future: Visual Commerce in Manufacturing

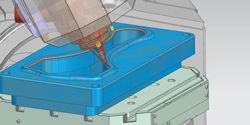

Machine Shop Robots Get Real

The 8 Wastes of Lean Manufacturing

Refurbishing Instead of Replacing

Records 31 to 45 of 824

First | Previous | Next | Last

Supply Chain - Featured Product

.jpg)

.jpg)

.jpg)