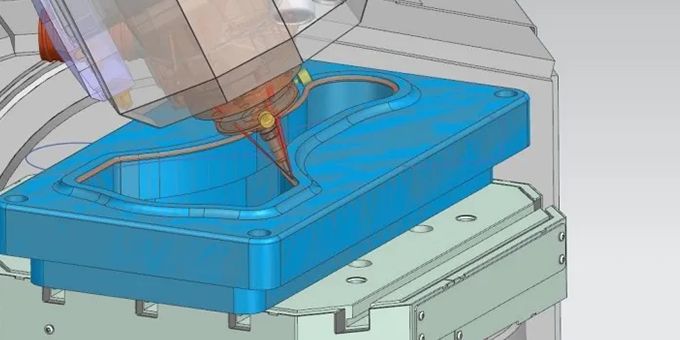

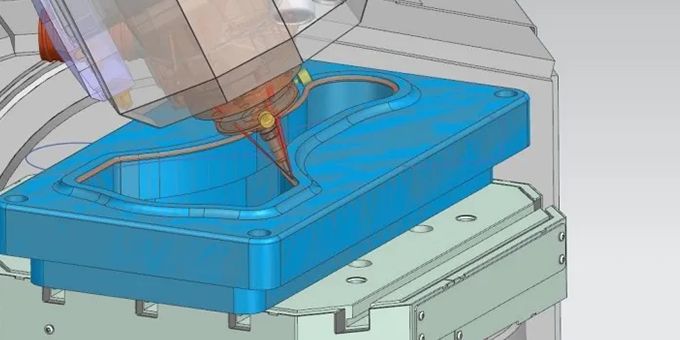

With cutting rings, a shearing tool removes the worn edges before they are built back up with 3D printing. Finally, the cutting rings are machined to the final shape.

Refurbishing Instead of Replacing

Refurbishing Instead of Replacing

Article from | Siemens

Reduce, reuse, and recycle are the watchwords of sustainable industries. However, until now, for many players in industry it was simply uneconomical to repair worn-out machine components. That’s changing with 3D metal printing machines from the CHIRON Group powered by Sinumerik One from Siemens.

What sounded like science fiction just a few years ago is now possible with a new product from the CHIRON Group: The 3D metal printer AM Cube, which employs laser metal deposition (LMD) technology. It is a veritable revolution in additive manufacturing (AM), as it can change the deposition head while a process is running in order to fulfill various requirements on a workpiece. For example, to achieve a high surface quality or a high deposition rate, or for internal and external coating. The AM Cube can also apply wire or powder in different stages of production.

Sinumerik One from Siemens drives the AM Cube. This digital-native computerized numerical control (CNC) system in combination with NX CAM uses digital twin technology to simulate and test work processes completely virtually before they are put into action. Users save time, resources, and costs. What’s more, Sinumerik One connects automation, competence in technology, and digitalization to form a single solution offering for more productivity. Thanks to this flexible platform and automatic deposition head change, the AM Cube can be used for coating and repairing components as well as for the near-net-shape production of semi-finished products. The AM Cube is a true multitalent.

Repair instead of replacing

Hammerwerk Fridingen counts on AM Cube for repairing cutting rings. “The ability to repair instead of replace is a valuable feature because it allows us to meet our sustainability goals,” says says Dominik Hipp, head of machine tool manufacturing, Hammerwerk Fridingen. An added benefit is less reliance on volatile supply chains, since parts can be repaired close to their place of use.

With cutting rings, a shearing tool removes the worn edges before they are built back up with 3D printing. Finally, the cutting rings are machined to the final shape. Thanks to this approach, the lifetime of a cutting tool is extended by a factor of 2.5. In practice, this means 40,000 cycles instead of the usual 16,000 before replacement is necessary. By renovating cutting rings, Hammerwerk Fridingen consumes fewer resources and saves time compared with manual processes or with using a cutting ring just once.

Use case under investigation: A big boost for the circular economy

Wind power is making a huge contribution to the world’s supply of renewable energy. Onshore and offshore turbines operate around the clock, all the while facing the full force of the wind.

Understandably, these strains take a toll on mechanical components, especially the gear wheels that connect the rotor to the generator. Proper maintenance, especially of the gear wheels, is essential to keep the turbines operating for their planned lifetime of 20 to 25 years.

In view of the role wind turbines play in sustainable energy production, refurbished would be the natural choice. “However, for gear wheels the decision is almost always made for new, because refurbishing can’t be done economically,” says Cedric Bardenhagen, who is key account manager at Siemens responsible for the CHIRON Group. But that could soon change. Siemens and the CHIRON Group have completed a study on the viability of using the AM Cube to cost-effectively refurbish these gear wheels.

Repair of cutting rings with the 3D metal printer AM Cube in practice. The result: significantly less material usage and a 3-fold increase in tool life (photo: CHIRON Group)

New business opportunities

Sinumerik One has the added benefit of increased productivity in machining operations by up to 30 percent. This is down to the fact that with Sinumerik One machining centers can achieve higher path velocities and greater productivity. Combined with the advanced additive and subtractive capabilities in NX CAM software, companies can industrialize additive manufacturing. The comprehensive Siemens technology enables machine builders to offer technology capable of refurbishing worn parts quickly, flexibly, and at a competitive price. These capabilities open the door for new business opportunities for companies like CHIRON Group and Hammerwerk Fridingen.

Perhaps even more important is the contribution this software development is making toward the circular economy. When maintenance staff is faced with the question of new or refurbished, they can increasingly choose the most ecofriendly option. “In a growing number of cases, that will be for a refurbished part,” concludes Till Oeschger, project manager AM Cube, CHIRON Group.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product