Learn when and why it is best to use digital pressure sensors in industrial applications and what types of features can help increase system safety, efficiency and reliability.

The Advantages of Digital Pressure Sensors in Industrial Applications

The Advantages of Digital Pressure Sensors in Industrial Applications

Martijn Stopel, Sr. Product Design Engineer | Sensata Technologies

Pressure sensors are used in a variety of industrial applications, ranging from hydraulics and pneumatics; water management, mobile hydraulics and off-highway vehicles; pumps and compressors; air conditioning and refrigeration systems to plant engineering and automation. They play a critical role in ensuring system pressures are within acceptable ranges and help to ensure reliable operation of the application. There are different advantages to using analog and digital pressure sensors, depending on the installation and system requirements.

When to Use a Digital vs an Analog Pressure Sensor System Design

One advantage of using analog pressure sensors is the simplicity in set-up if the existing system is based on analog control. If only one signal is needed on location for measuring dynamic processes, an analog sensor coupled to an analog-to-digital (ADC) converter would be a simpler solution as opposed to a digital pressure sensor which requires a specified protocol to establish communication with the device. If system electronics need very fast active feedback control loops, pure analog pressure sensors are the best solution. For systems that do not require a response time of faster than approximately 0.5ms, digital pressure sensors should be considered since they simplify networking with multiple digital devices and make the system more future-proof.

The right time to consider switching to digital pressure sensors in an analog system is when upgrading the components to include programmable microchips. Now that modern microchips are more affordable and more easily programmed, incorporating them into components like pressure sensors simplifies maintenance and system upgrades. This saves on potential hardware costs as digital sensors can then be updated with software instead of replacing entire components.

In applications with battery-operated systems, like in remote locations, battery-powered digital sensors with low power consumption are preferred over analog pressure sensors, which require constant power. Digital pressure sensors are easier to control and provide power-saving benefits to the system. For example, the ability to schedule when digital pressure sensors record or sleep can reduce power consumption by up to 500x when compared to analog sensors.

The plug-and-play design and shorter cable lengths of digital pressure sensors streamline system set-up and reduce the overall cost of installation in applications that are set up for digital communications. When digital pressure sensors are combined with GPS trackers, remote cloud-based systems can be located and monitored in real-time from afar.

Digital pressure sensors provide many advantages such as lower power consumption, minimum electrical noise, sensor diagnostics and remote monitoring.

Benefits of Digital Pressure Sensors

Once the user has assessed whether an analog or digital pressure sensor is most appropriate for the given application, understanding some of the beneficial features that digital pressure sensors offer industrial applications will help improve the system’s safety, efficiency and reliability.

A Brief Comparison of Inter-Integrated Circuit (I2C) and Serial Peripheral Interface (SPI)

Two common digital communication protocols used in industrial applications are Inter-Integrated Circuit (I2C) and Serial Peripheral Interface (SPI). I2C works better with more complex networks as the installation requires fewer wires. In addition, I2C allows for multiple masters/slaves whereas SPI only allows for a single master/multi-slave network. SPI is the ideal solution for simpler networks and when higher speed and data transfer is required, like reading or writing to an SD-card or recording images.

Output Signals & Sensor Diagnostics

An important distinction between analog and digital pressure sensors is that analog provides only one output signal where digital sensors provide two or more, such as pressure and temperature signals along with sensor diagnostics. In gas cylinder measuring applications for example, the additional temperature information extends the pressure signal into a more comprehensive measurement that allows for the calculation of gas’s volume. Digital sensors also provide diagnostic data which includes key information like the reliability of the signal, signal readiness, and live failures, enabling preventive maintenance and reducing potential downtime.

This diagnostic data provides the detailed status of the sensor, such as if a sensor element is broken, if a supply voltage was correct, or if there is an updated value in the sensor that can be fetched. Compared to an analog sensor which does not provide detailed information about signal errors, diagnostic data from digital sensors enables better decision-making when trouble-shooting errors.

Another benefit of digital pressure sensors is that they are available with features such as alarms to alert operators of conditions outside of set parameters and the ability to control the timing and intervals of readings which helps to lower overall power consumption. With numerous outputs and diagnostics available in digital pressure sensors, the whole system is more robust and efficient because the data provides the customer with a more comprehensive assessment of the system’s operation. In addition to expanding measurement and self-diagnostic capabilities, the use of digital pressure sensors allows for faster development and implementation of Industrial Internet of Things (IIoT) systems and big data applications.

Digital pressure sensors like Sensata’s PTE7300 feature additional electronics onboard that suppress noise from sources such as WiFi, Bluetooth, and GSM and ISM bands. In addition, they feature low power consumption for battery operation, fast response time, increased sensor diagnostics, and sensor communication integrity check using cyclic redundancy check (CRC).

Environmental Noise

Electromagnetically noisy environments such as those close to motors, long cable runs, or radio sources could present signal interference challenges for components such as pressure sensors. To prevent Electromagnetic Interference (EMI) in analog pressure sensors, the designs need to include proper signal conditioning like

grounded metal shielding or additional passive electrical components, as electrical noise could cause faulty signal readings. All analog outputs are highly susceptible to EMI; however, using a 4-20mA analog output can help to circumvent this interference.

In contrast, digital pressure sensors are not as vulnerable to environmental noise compared to the analog equivalents, so they provide a great solution for applications where EMI is a concern, and the desired output is not specifically 4-20mA. It is important to note that different types of digital pressure sensors provide varying degrees of EMI robustness, depending on the application. Inter-Integrated Circuit (I2C) and Serial Peripheral Interface (SPI) digital protocols are ideal for short distance or compact systems with cable runs under 5m long, though the precise allowable length is highly dependent on the type of cable and pull-up resistors being used. For systems that require longer cable runs up to 30m, CANopen (optional shielding) or IO-Link digital pressure sensors would be the best option for EMI resistance, though they would require higher power consumption than their I2C and Serial Peripheral Interface (SPI) counterparts.

Data Protection with Cyclic Redundancy Check (CRC) Checking

Digital sensors provide the option of including CRC in the chip to help assure customers that they can rely on the signals. The CRC of the communication data is additional to the integrity check of the internal chip memory and allows users to validate 100% of the sensor output, providing an extra measure of data protection for the sensor. CRC features are ideal for pressure sensor applications in noisy environments, like when installed close to a transmitter in a cloud-based system. In such a scenario, there is an increased risk of noise interfering with the sensor’s chip and producing a bit flip which could alter the communication message. The CRC on the memory integrity will protect the internal memory from such corruption and repair if needed. Likewise, some digital sensors also provide an additional CRC on the data communication which indicates corruption of data transferred between the sensor and controller and could trigger another attempt to assess a proper sensor readout. In some cases, end users circumvent this by interleaving the communication with the sensor with the external communication (for example to the cloud, a gateway or a controller). CRC simplifies this process and gives the designer more flexibility. In addition to data validity checking, some manufacturers include more electronics that suppress noise from sources such as WiFi, Bluetooth and GSM and ISM bands, further protecting data validity.

Digital Pressure Sensors at Work Enabling Smart Water Distribution Networks

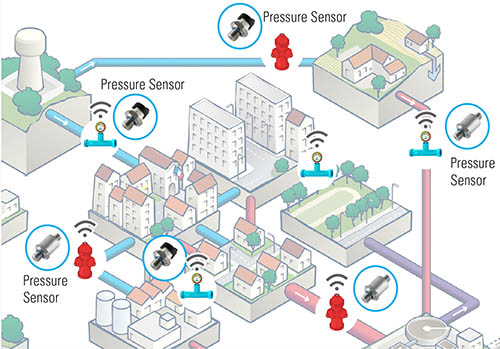

The loss of water either through leaks, metering inaccuracies, unauthorized consumption or a combination of the three is an ongoing challenge for large water distribution networks. Applying digital pressure sensors with low power consumption at nodes throughout the distribution network is a practical and cost-effective approach to mapping an area’s water distribution network and allows utilities to detect and target areas with unexpected water loss.

When applied at the nodes throughout a water distribution network, digital pressure sensors can help identify areas of unexpected water loss, allowing for effective trouble-shooting and improving system efficiency.

Pressure sensors ideal for these applications typically feature either a fully hermetic design rated to IP69K ingress protection or are modular to allow customers more design flexibility. To prevent water leaking into the sensor for the duration of the application’s life, some pressure sensor manufacturers utilize a glass-to-metal seal connection. A glass-to-metal seal is impervious and creates a hermetic seal on the “top” of the sensor, contributing to a sensor’s IP69K rating. This seal means that the sensor is always measuring the pressure difference between what is in the application and the air surrounding it, preventing offset drift.

Improving Pressurized Gas System Conditioning

Pressure sensors play several important roles in monitoring and transporting pressurized air and medical gas throughout distribution networks. In these types of applications, pressure transducers could be responsible for compressor control and a variety of monitoring functions including of the intake and output flow-rate, gas cylinder depletion and air filter status. While a pressure signal alone gives an indirect measurement of the amount of gas particles at one location of the system, the combination of both pressure and temperature feedback that digital pressure sensors provide delivers a much better estimate of the amount of gas at the location, and therefore better system conditioning and monitoring. This allows system developers to get closer to the ideal working conditions for the application. Using digital pressure sensors in these systems could enable the creation of custom dashboards that monitor the fullness of gas bottles and their locations, allowing operators to more efficiently troubleshoot and maintain the system.

Though there are still installations where using analog pressure sensors make the most sense, there is a growing number of applications in industry 4.0 that benefit from using their digital counterparts. From EMI resistance and scalable networking to sensor diagnostics and data protection, digital pressure sensors enable remote monitoring and predictive maintenance, increasing the efficiency and reliability of the system. Robust sensor designs that feature specifications such as IP69K ratings, additional data integrity checks and extensive onboard electronics for EMI protection will help prolong service life and reduce potential signal errors.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product