Maximizing OEE with Smart Selection of Electric Linear Actuators

How a careful actuator selection and modern motion system design can unlock higher availability, performance, and product quality in automated manufacturing.

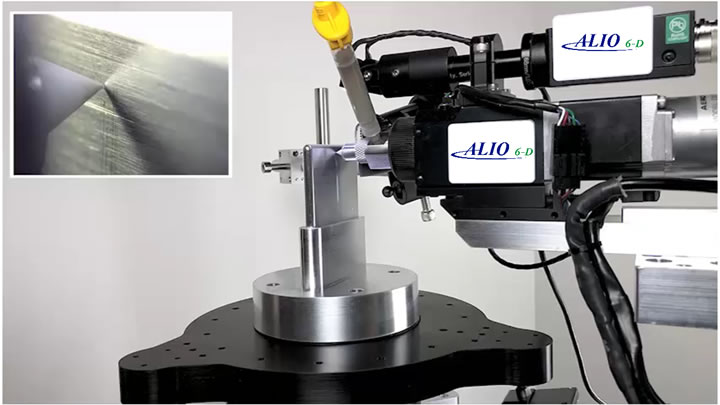

Demonstrating Flexible, Powerful 5-axis Laser Micromachining

With a suitable system, it is possible to control the entire micro-machining process - the laser, scan head and workpiece positioning - to produce macro-sized components to sub-micrometer dimensional tolerances.

Custom linear motion solution drives Swiss river restoration research project

The project required smooth, uninterrupted motion across the record-long dimensions, which the Institute achieved through collaboration with linear motion manufacturer Thomson Industries and automation expert König Lineartechnik.

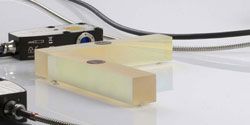

What is the advantage of buying linear guideways with integrated linear encoder pre-installed?

Direct measurement is usually favorable over indirect position measurement. In the case of integrating direct position measurement, there are two primary methods of adding position measurement to an axis.

From Ready-Made Motion Code to Built-In Diagnostics, Unitronics 'Servo Made Simple' Increases Profit - By Saving Time.

Say goodbye to complexity-you can now benefit from Plug-and-Play integration, and remotely commission, configure, program, run, and troubleshoot your motion control systems. Meet Servo Made Simple from Unitronics.

SUPPLIER SELECTION FOR CRITICAL MOTION CONTROL APPLICATIONS

In this article, I attempt to arm manufacturers with the questions that they need to ask to ensure that the motion control solution option chosen is right first time and up to the job. These questions should ideally focus on not just capabilities but also values.

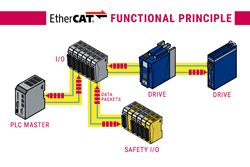

5 Advantages of Using EtherCAT for Motion Control

EtherCAT is proven to optimize machine performance with its deterministic performance, flexible topology, and diverse set of features. To better understand why users should use EtherCAT, let's review its history, how it works, and the problems it solves.

VFDs-How Smart Selection Saves on Costs

Integrating VFDs into your applications enables you to implement robust, precise control that cuts your energy requirements; built-in communication-based control reduces your wiring and IO modules costs.

High Precision Linear Motor Stages for Industrial Automation

Precision industrial motion systems are used in test, assembly or laser micro-machining of high precision and high value components and in electronics, optics, and photonics manufacturing, to name a few.

Discussing ATX West with HEIDENHAIN

Motion control is at the core of automation technology. Whether it is 3D printing, robotics, semiconductor manufacturing or machine tools, HEIDENHAIN offers the precision feedback in both linear and angular, as well as positioning systems and controls. Booth #4466

Ultra-Precision Motion Control - Key Considerations for Supplier Selection

As the demand for more and more exacting motion control increases across numerous industry sectors, it is vital that before investing, customers are informed enough to make sure that they select the right solution for their specific application.

Encoders Hold the Key to Ultra-accurate Motion Control

Aerotech, continuing its commitment to the art and science of motion control, looks to Renishaw for versatile, high-precision laser interferometer encoders for its medical stages.

Applications of Nanometer-Level Precision Motion Control Solutions

Crucial to many exacting applications requiring nanometer-level accuracy and repeatability are best-in-class motion control solutions. This article will look at the top-end solution in terms of accuracy and repeatability...

Celera Motion Case Study - Precision Rotary Axis Control

The customer required precision rotary axis control in the lowest profile form factor for multiple sequential robot arm joints. Key additional requirements included minimal movement at start-up to report absolute position...

Top Article for 2018 - Machine Automation Explained

Motion control systems are ideal for use in applications that require product positioning, rapid start and stop motions and synchronization of unconnected elements. PLCs have the capability to offer the required signals for commanding stepper systems and servos...

Records 1 to 15 of 27

Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Manufacturing and Automation - Featured Company

EXAIR

EXAIR intelligent compressed air® products solve problems in industrial plants while reducing compressed air consumption and increasing safety for personnel. We have the largest variety of sizes, materials and performance characteristics in order to provide the best solution for your processes and problems.

Our products are commonly used to conserve air, cool processes or parts, convey material, clean surfaces or coat surfaces. EXAIR's 15 extensive product lines include air knives, air wipes, air nozzles and jets, atomizing nozzles, static eliminators, cold gun air coolant systems, air amplifiers, safety air guns, air operated conveyors, industrial housekeeping products, vortex tubes and spot cooling products, cabinet cooler systems, vacuum generators, compressed air optimization products, and associated accessories.

Products meet OSHA standards and are CE and RoHS compliant. Five-year warranty on compressed air products and one-year warranty on accessories and electrically powered products.