Motion control is at the core of automation technology. Whether it is 3D printing, robotics, semiconductor manufacturing or machine tools, HEIDENHAIN offers the precision feedback in both linear and angular, as well as positioning systems and controls. Booth #4466

Q&A with | HEIDENHAIN

Tell us about your Company.

HEIDENHAIN CORPORATION is the North American subsidiary of the German company DR. JOHANNES HEIDENHAIN GmbH, a leading international manufacturer of precision measurement and control equipment. This superior technology is utilized within high precision motion control and machining systems worldwide. It is headquartered in Schaumburg, IL, and San Jose, CA, and has been serving the U.S. industry for over 50 years. Here nine company brands are represented.

What makes your booth a must visit for Expo Attendees?

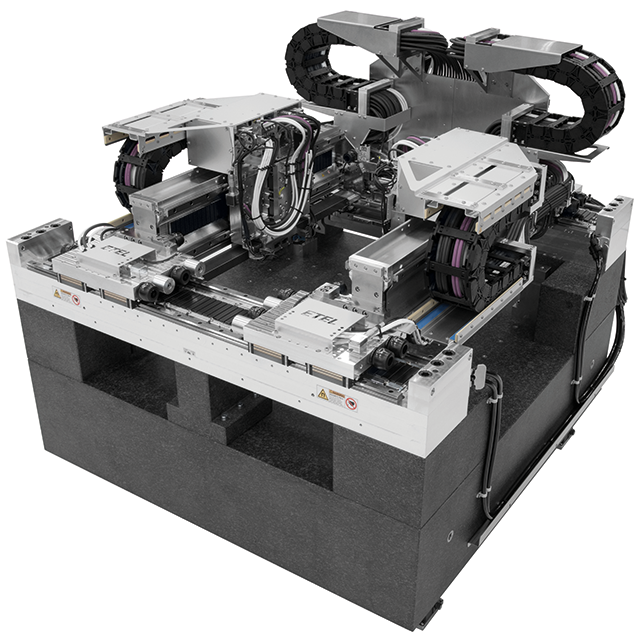

Visitors must see the latest in advanced motion control technology from ETEL which is a HEIDENHAIN brand. This includes actuators to torque motors and complete motion systems.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

We as an exhibitor are, obviously, most interested in connecting with customers with which we can provide motion solutions. We are happy to be included in this great gathering in order to start to meet those needs.

Advanced Manufacturing is undertaking rapid advancements, be it 3D Printing and the materials used to automation and robotics. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

Motion control is at the core of automation technology. Whether it is 3D printing, robotics, semiconductor manufacturing or machine tools, HEIDENHAIN offers the precision feedback in both linear and angular, as well as positioning systems and controls.

Give us your thoughts on what the future holds for manufacturers and automation technology.

Better connection, speed and accuracy = throughput. No matter how one slices it, that’s the future.

If you like this article you may like "Advanced Metrology Tools Enable Reliable Engine Light-Weighting"

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product