How to Upskill Frontline Employees as Industry 4.0 Gains Traction

How VR and AR are Creating the Next Generation of Welders

8 Causes of Lost Productivity in Manufacturing and How Managers Can Address Them in 2022

2022 Online Training Trends: What to Expect in Safety and Beyond

Michigan Economic Development Corp. (MEDC) Starts Preparing Companies for the Future of Manufacturing

Manufacturing Impact: Rising Consumption of Entertainment Drives Demand For 3D Animated Content

Tips to Help Manufacturers Address the 2021 Labor Shortage

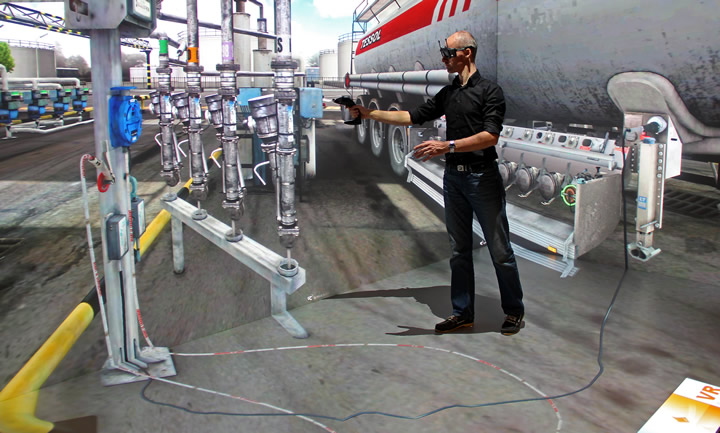

How VR can Ensure Manufacturing Safety

Prestigious 140+ Year Old University Delivers Advanced Engineering and Technical Training With Method X

Transforming Workplace Training With the Most Effective Digital and Augmented Reality Tools

Post-Pandemic Operations Must Incorporate Real People into the Automation Process

Routes to Professional Success in Automation

MFG Day 2020 to Educate Students Across the Country on the Importance of the Modern Manufacturing Industry

Integrated Engineering Program Opens Up Opportunities for Students

50 Ways to Impact Your Business with AI

Records 16 to 30 of 84

First | Previous | Next | Last

Featured Product

PI USA - Nano- and Micro- Essentials Products

Manufacturing and Automation - Featured Company

.jpg)

.jpg)

.jpg)

.jpg)