Tips to Help Manufacturers Address the 2021 Labor Shortage

The U.S. has been seeing declines in skilled labor during the past few years as experienced and knowledgeable employees continue to retire while fewer are choosing employment in factories or skilled trades.

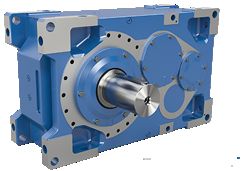

NORD MAXXDRIVE Industrial Gear Units: Built for the Toughest Applications

Rugged, reliable, and thermally optimized, NORD's industrial gear units are ready to take on the most demanding industrial drive technology requirements.

Change in the technology buzzword blizzard - Automation specialist explains the latest trend: hyper-automation

Hyper-automation, as the name may suggest, relates to excessive automation. This is something that Elon Musk pleaded guilty to in 2018 after the production line for the Tesla Model 3 came to a complete halt for four days.

How Are Mechatronics and Industrial Automation Different?

Mechatronics and industrial automation are two fields that overlap to some extent. But they have their differences, too. Here's a definition of each, plus how they benefit the manufacturing sector.

Retrofitting Legacy Equipment

Here Jonathan Wilkins, director at EU Automation, discusses the issues and solutions surrounding retrofitting legacy equipment with smart technology.

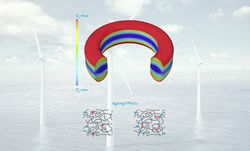

Accurate long-term predictions - Freudenberg Sealing Technologies' new method shows how static seals actually age

Freudenberg Sealing Technologies has now developed a method that takes material changes at the molecular level into account when predicting the long-term durability of seals.

The Three-step Guide to Buying Automation

We've all heard the phrase, 'like a kid in a candy store'. Visiting automation trade shows can leave even the calmest visitors eager to get their hands on some automation action. Before parting with your cash, Claudia Jarrett suggests three important questions to ask.

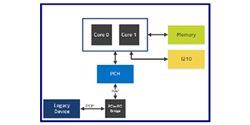

Effect of PCI Devices on Automation Systems

Industry 4.0 is changing systems architecture across all domains in industrial automation. Upcoming edge computing architectures use virtualization for scaling dedicated applications with deterministic key performance indicators (KPIs) on a heterogeneous operating systems.

Tips and Tricks for Implementing Automation in Your Manufacturing Plant

IoT and connected devices are making the development process more transparent. The technology also allows plant managers and overseers to accurately review operations, which leads to a more positive direction for everyone.

International Manufacturing Technology Show

Now, with connectivity, controls, process integration and automation, job shops and manufacturers can harness more uptime from their CNCs. Visit more than 350 companies in the Metal Cutting Pavilion.

Top 5 Reasons to Use Flat Cables Instead of Round

Flat Cables have many technical and performance enhancing advantages over round cables, so Cicoil has released a New Video to clearly illustrate "The Top 5 Reasons to Use Flat Cable in your Design"

ManufacturingTomorrow - Special Tradeshow Coverage

IMTS 2018

IMTS 2018 takes place at McCormick Place in Chicago, IL September 10th - 15th. This ManufacturingTomorrow.com Special Tradeshow report aims to bring you news, articles and products from this years event.

ABB is leaving the repair shop after transitional year - CEO

John Revill, Oliver Hirt for Reuters: "The last couple of years ABB was in the repair shop and now we are coming out. With political stability and digitalisation we have positive conditions and a better platform to participate in the upturn,"

Kuka Showcases Robotic Demos at TechCenter Grand Opening

Candace Roulo for SME: The grand opening featured 13 live robotic automation demonstrations, tours of the new TechCenter, and presentations on new technology.

Apple and GE just put iOS inside Industry 4.0

Jonny Evans for ComputerWorld: Apple and GEs new agreement opens the door for further iOS deployment across industry infrastructure and puts Apple at the core of digital transformation.

Records 1 to 15 of 20

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Strain wave gearheads are ideal for use in applications requiring precision motion control and high torque transmission in a compact design. maxon strain wave gearheads are a specialized type of gearhead where precision and compact design are crucial. This type of gearhead is often used in applications in a confined space. With their advanced gear tooth design, maxon's strain wave gearheads provide high efficiency and good back drivability. Typical applications include:

Robotics, Aerospace, Medical technology and Optical systems

.

Manufacturing and Automation - Featured Company

The Wire Association International, Inc. (WAI)

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry.

WAI hosts trade expositions, technical conferences, and educational programs.