We've all heard the phrase, 'like a kid in a candy store'. Visiting automation trade shows can leave even the calmest visitors eager to get their hands on some automation action. Before parting with your cash, Claudia Jarrett suggests three important questions to ask.

The Three-step Guide to Buying Automation

The Three-step Guide to Buying Automation

Claudia Jarrett | EU Automation

How long is the warranty?

Sounds obvious, right? Under the intense lighting of a trade show venue however, asking about warranty can easily be forgotten. Take the time to establish how long the warranty covers your new product for, and what actually counts as a warranty claim. Take a six-axis robot as an example. Does the warranty cover the detachable parts, should as the grip pads or nozzles?

Remember, even reconditioned parts should come with a 12-month warranty. Once this formality is established — and confirmed in writing — you can rest assured you won’t be left in a warranty war should the equipment break down.

Is the part compatible with existing machinery?

Buying a new machine without any consideration for integration is like buying a pet goat and expecting it to get on with your cats. It’s not impossible, but it’s unlikely. Factories are an intricate ecosystem, and one incompatible part will have a knock-on effect on other machines downstream.

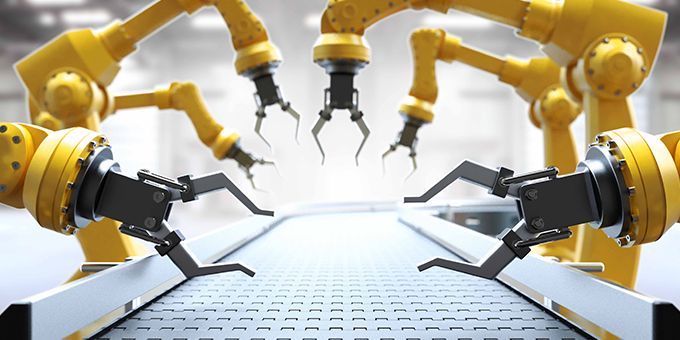

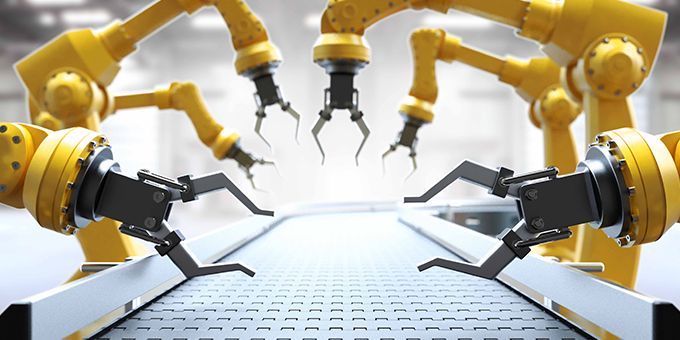

By the time you’re signing on the dotted line for a new robot, you should already know which part of production it will be used for. What equipment will it interact with? Perhaps it’s a pick-and-place robot for use alongside a conveyor. In this case, you will need to ensure the line’s machine vision is compatible with both pieces of equipment.

You should also consider whether your production line will enable equipment to work to its full potential. Existing machinery may mean the robot cannot deliver the 0.4 second cycle time it can achieve, as the conveyor cannot accommodate this speed. As a result, a bottleneck scenario is created.

In cases like this, it could be argued you haven’t targeted the best pain point in production. Ask these questions first, and you will avoid disappointment later.

Will it fit?

Have you considered the layout of your shop floor? Before making a purchase, there are factory floor layout simulators available to see what your reorganised floor would look like with a new part. When simulating this, you shouldn’t forget the peripheral equipment that may be required for your new part. For instance, buying a robot may require safety fencing, adding a few extra metres to the machine’s footprint.

If your part requires fencing, you might also require additional safety automation that needs to be purchased. Mat guards and industrial light curtains are both examples of necessary, but sometimes forgotten costs. Does the budget allow for these extras?

Visiting a trade show this year? Stop, think and breathe. There’s a lot of candy up for grabs, but you need to unwrap a few truths before parting with your cash.

If you like this article you may like "Predictive Analytics vs Machine Learning"

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product