Epson Elevates Automation to New Heights with Expanded 6-Axis Robot Lineup

Leveraging four decades of expertise, the C-B Series offers next-level performance and flexibility in a compact footprint. It features advanced GYROPLUS® vibration reduction technology for fast production speeds and smooth motion control.

How Small Manufacturers are Building a Business Case for Robotics

Smaller manufacturers are the fastest-growing area of industrial robotics today, driven by the need for new collaborative robotics systems.

EU Automation publishes new guide: How to Get Robotics Right - Avoiding the Common Costly Mistakes of Automation Adoption

The useful guide provides engineers with valuable information about how to introduce automation into manufacturing practices successfully, so they can realise the full potential of robotics

Breaking down Walls to Build e-Factories

Thomas Burke, Global Strategic Advisor at CC-Link Partner Association (CLPA), looks at how industrial automation vendors, machine builders, and end users can futureproof robotic systems with value-adding network technologies.

Is RaaS the way to go?

Back in 2017, the International Data Corporation (IDC) predicted that 30 percent of commercial robotic applications will be in the form of Robots as a Service (RaaS) by 2019. Was this forecast accurate?

The Future is Here with Robot Guidance Systems

Manufacturers are facing a number of challenges, but perhaps the biggest of them all is the implementation of automated material handling solutions. SICK, Inc. has the answer to this problem with a system-solution approach.

Innovative Manufacturers Should Embed Automated Systems in Production Processes

Precision tools improve process control and result in higher product quality.

ManufacturingTomorrow - Special Tradeshow Coverage

IMTS 2018

IMTS 2018 takes place at McCormick Place in Chicago, IL September 10th - 15th. This ManufacturingTomorrow.com Special Tradeshow report aims to bring you news, articles and products from this years event.

Manufacturing Challenges and Industry 4.0

As we move deeper into the Industry 4.0 era, advancements in automation, artificial intelligence, machine learning, cloud computing and big data play an increasingly important role in how factories operate.

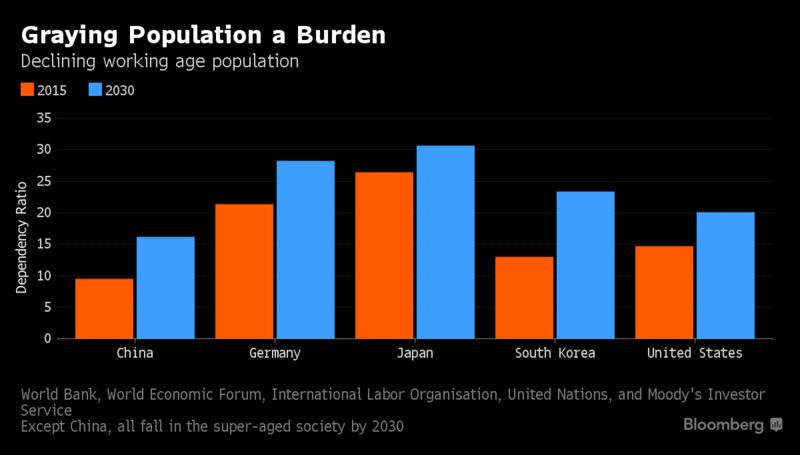

Robots May Help Defuse Demographic Time Bomb in Japan, Germany

Anirban Nag for Bloomberg: Robots to offset negative impact of slower labor force growth. Emerging markets wont be so lucky, Moodys report says

Getting Started with Collaborative Robots - Part 4 - Assess Your Potential Applications

Documenting the actual process will allow you to evaluate if the process can be automated. This will also give you a starting point on cell performance and improvement opportunities.

Records 1 to 11 of 11

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Strain wave gearheads are ideal for use in applications requiring precision motion control and high torque transmission in a compact design. maxon strain wave gearheads are a specialized type of gearhead where precision and compact design are crucial. This type of gearhead is often used in applications in a confined space. With their advanced gear tooth design, maxon's strain wave gearheads provide high efficiency and good back drivability. Typical applications include:

Robotics, Aerospace, Medical technology and Optical systems

.

Manufacturing and Automation - Featured Company

PI USA (Physik Instrumente)

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1700 people worldwide. PI's customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors and aerospace.

.jpg)