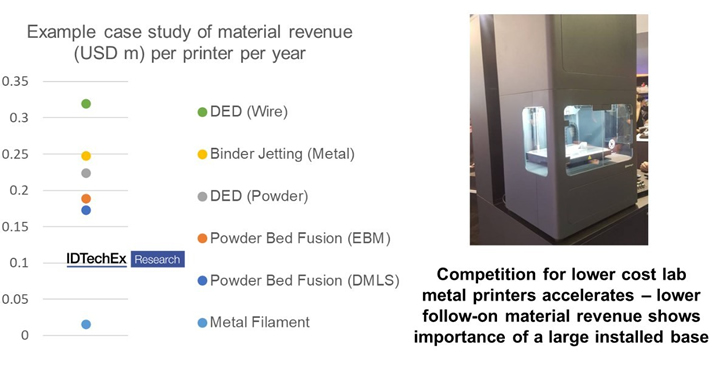

Metal Additive Manufacturing: The Cheaper the Better, asks IDTechEx

ADDERE REDUCES THE PART COUNT IN LARGE SCALE ASSEMBLIES

Quick Guide to Metal Additive Manufacturing for Industrial Components

U.S. Army Research Lab Selects 3D Systems to Develop World's Largest, Fastest Metal Powder 3D Printer

The Technology of 3D Metal Printing

Who's Afraid of the Big Tall Build?

A Q&A Guide to Etching Metals

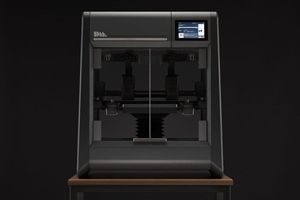

KDT Leads $160 Million Investment in Desktop Metal to Drive the Adoption of the Company's Metal 3D Printers for Mass Production and the World's First Office-Friendly Metal 3D Printing System

Talking IMTS with Desktop Metal

Sciaky, Inc. and Concurrent Technologies Corporation Enter Strategic Partnership to Expand the Reach of Metal Additive Manufacturing

FluidFM® μ3Dprinter - A new function allows unique pinpoint metal additive manufacturing

3D printing doubles the strength of stainless steel

Laser ultrasound: the future of metal 3D printing?

100x faster, 10x cheaper: 3D metal printing is about to go mainstream

Desktop Metal gets $115 million investment in 3D printing technology

Records 16 to 30 of 36

First | Previous | Next | Last

Featured Product

NVIDIA RTX PRO™ BLACKWELL DESKTOP GPUs N

Manufacturing and Automation - Featured Company